5 key performance indicators to track in molding machine production

2025/10/15 By le zhan

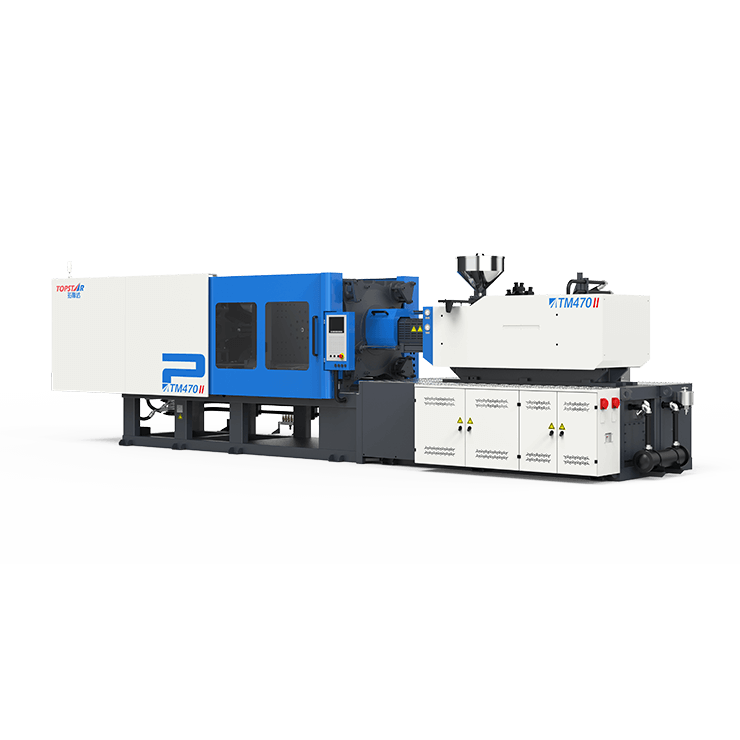

Inadequate monitoring of molding machine performance in injection molding production can lead to scrap, rework, and financial losses. As a Topstar injection molding machine user, you are responsible for your production results when using our machines. Therefore, we have leveraged our experience as a manufacturer to provide you with five performance indicators to track during production.

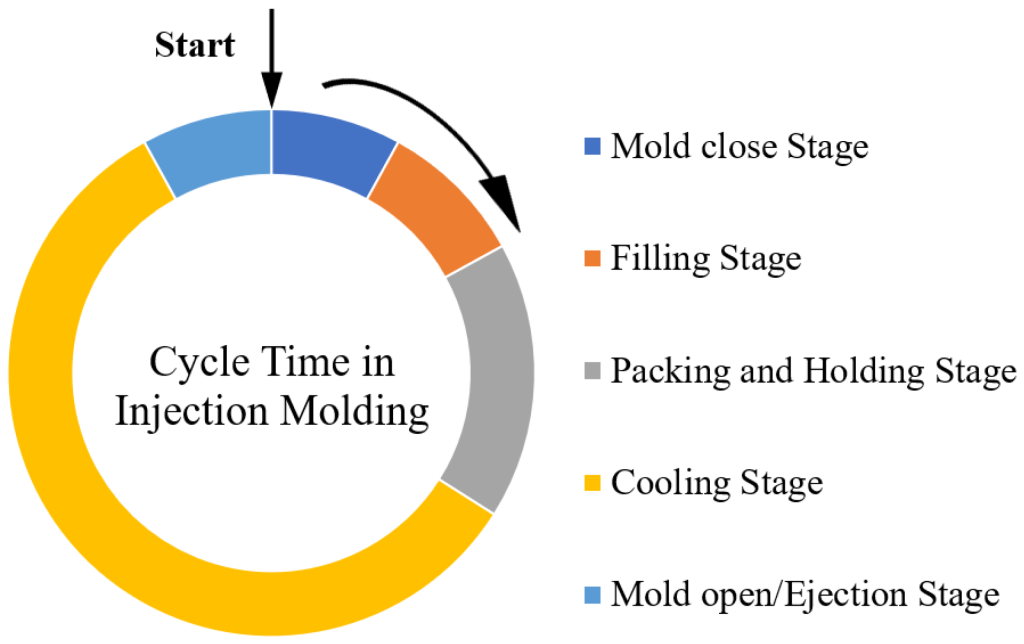

Observing Cycle Time Consistency: The Foundation of Efficient Molding Machine Production

Cycle time in a molding machine is the time it takes to complete injection, cooling, and ejection. Even slight variations can have a significant cumulative impact: a 2-second cycle delay on a Topstar TEll 160t injection molding machine producing 10,000 parts per day can result in a loss of 5,500 parts per week.

How to Track on Your Injection Molding Machine:

Access real-time cycle time data directly from the Topstar HMI. Most models record the time for each cycle and display an average of 10, 50, or 100 parts. Set a target cycle time and flag any deviations exceeding ±1 second.

Tracking is crucial because it can identify issues that could lead to inconsistent cycle times, such as clogged cooling lines (extended cooling time), worn ejector pins (slower ejection speed), or incorrect injection speed, allowing for timely replacement.

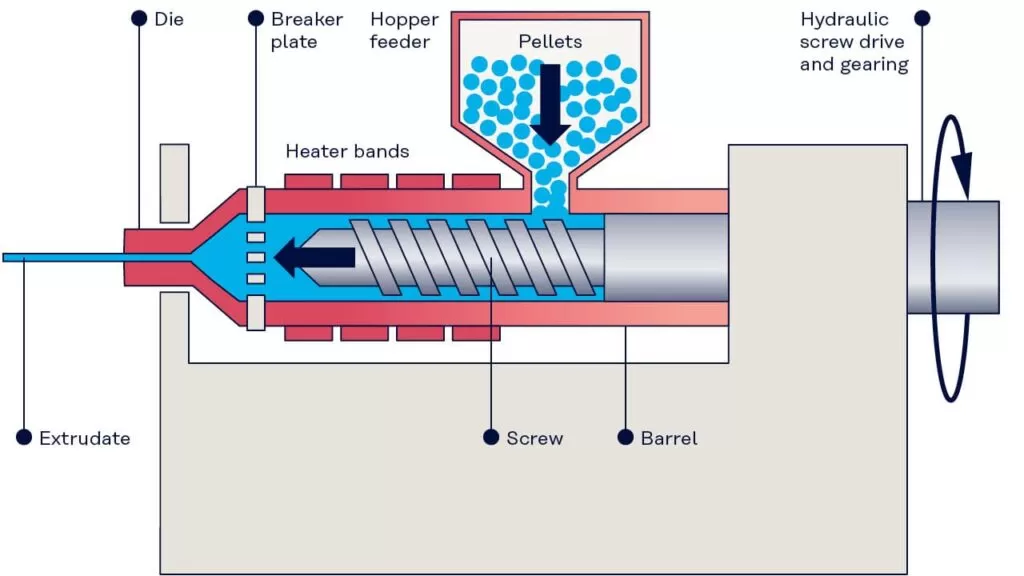

Ensuring shot weight accuracy: Ensures the molding machine can deliver accurate shot weight.

Shot weight determines part size and integrity. A deviation of even 0.5 grams from the target value can result in overfill (flash) or underfill (voids), both of which require scrap or rework.

Topstar molding machines have built-in load cells that measure shot weight during each cycle. This data is viewed on the HMI, and tolerances are set to ±0.1 grams for critical parts and ±0.3 grams for less precise parts. For more stringent requirements, “shot weight verification” can be performed every two hours: five parts are weighed consecutively on a precision scale and compared to the data recorded by the machine.

Observing Injection Pressure Stability

In injection molding, consistent injection pressure is crucial to avoid part defects. Voids, flash, or uneven filling can impact final product quality. Topstar’s injection molding machines all utilize proportional backpressure control to maintain stable pressure, but wear or incorrect settings can affect this stability. During production, you can monitor the real-time pressure during the injection process by tracking the pressure curve on the injection molding machine’s HMI. A stable curve should have smooth peaks and align with the target pressure. For example, PC resin should be at 1,800 bar. Record pressure data daily and note any deviations exceeding ±50 bar, as this is the typical defect threshold.

A packaging customer using a Topstar TMll series injection molding machine noticed pressure spikes as high as 2,100 bar (target pressure: 1,900 bar), resulting in flash on bottle caps. After inspecting the mold, they discovered a clogged vent. After cleaning, the pressure stabilized, and flash defects were reduced by 85%.

Monitor temperature uniformity to maintain resin quality in the barrel and mold

Uneven temperatures within the molding machine barrel or mold can lead to resin degradation or flow problems. Topstar injection molding machines utilize zone-controlled barrel heating and mold temperature controllers with PID control. Regular monitoring ensures temperature consistency. During daily production, each heating zone is checked via the HMI, with a reasonable target deviation of ±1°C. Thermal sensors are also used to measure the temperature at four points on the mold surface (top, bottom, left, and right). The target temperature deviation is also ±1°C.

A toy manufacturer experienced part cracking during assembly. Tracking revealed that the temperature in barrel zone 3 reached as high as 240°C (target: 230°C), causing ABS resin degradation. Lowering the temperature in this zone resolved the brittleness issue and eliminated part failures.

Record the defect rate for each batch

The percentage of defective parts per batch is the ultimate key metric, as it links all other metrics to actual quality. Tracking the defect rate helps pinpoint the issue with the molding machine. For example, you can conduct a “100-part audit” every shift: inspect parts for common defects (flash, voids, warpage) and record the number of defects found. Use Topstar’s data logging capabilities to correlate defects with other KPIs. For example, “90% of warped parts occur when cycle times are > 32 seconds.” For one furniture parts client we work with, they tracked a 2.5% defect rate for warped parts. Cross-referencing cycle time data, they found that warpage increased dramatically when cooling times fell below 15 seconds. Increasing the cooling time to 18 seconds reduced the defect rate to 0.3%.

Take Control of Your Injection Molding Production

Tracking these five KPIs is more than just a task; it is about taking control of the quality of your injection molding production. When using Topstar injection molding machines, the built-in HMI simplifies monitoring and data logging, allowing you to identify problems early, reduce waste, and deliver consistent parts to your customers. By doing so, you ensure your molding machines are operating optimally and that your final parts meet your quality standards.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/10/15

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/10/15

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/10/15

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/10/15

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar