We investigated a large amount of information about the injection molding machine industry, studied the market dynamics of the entire industry, and wrote this practical report based on our years of experience. The purpose is to provide our peers or the plastic manufacturing industry using injection molding machines with a better understanding of injection molding or injection molding machines. This report focuses on the global injection molding machine market, emphasizing its regional segmentation and dynamics. Let’s share with you several aspects. Let’s take a look!

How do they work?

Injection molding injects molten plastic into a mold cavity and then cools it. Injection molding machines use pressure to inject molten plastic into mold cavities at high speeds to form parts ranging from small consumer goods such as toys, phone cases, and pens to vital automotive components such as bumpers or fenders.

There are two different types of molds in this process: open-face molds and closed-face molds. Open molds have a hollow cavity through which material can enter. A closed-face mold has a closed hole into which material enters through a gate on its side. Both types have similarities in that they use runner and gate tools to help direct the flow path to specific areas, they require a separate process of heating the plastic material before use, and they need a cooling mechanism once injection occurs. This way, the parts don’t fuse during the hot gas removal stage.

Different applications of injection molding machines!

Injection molding machines are suitable for many purposes, including manufacturing and engineering. In manufacturing, injection molding machines are commonly used to produce molds and parts for various products. These can include cars, toys, and even furniture. The process involves injecting heated plastic into a prepared cavity and removing the finished product from the mold.

The demand for injection molding machines in the healthcare industry is growing significantly, mainly due to their use in products such as respiratory care and diabetes drug delivery systems. These products provide mobility and convenience for an aging population. Injection molding is often used to produce high-volume, consistent medical components. Using injection molding processes helps develop high-quality, purpose-built, cost-effective medical devices.

The packaging industry also has a high demand for injection molding. The increasingly fierce competition among packaging manufacturers has led to the use of different types of packaging, which has stimulated the development of the rigid packaging market and further encouraged the packaging industry’s demand for injection molding machines.

Design and structure of an injection molding machine

Injection molding machines are suitable for producing plastic parts. They are ideal for many industries, including automotive, consumer electronics, and medical. Example: In the automotive industry, injection molding machines are suitable for making plastic parts such as car bumpers and headlights. They also produce plastic parts for vehicles that need to be durable but light enough to transport.

Plastics are essential in consumer electronics applications because they are less expensive while providing the required strength and durability. Plastics are easier to mold into complex shapes because they don’t require costly processes like die casting!

The injection molding process is a cost-effective method of producing high-quality products!

Injection molding is a process that uses high pressure to inject heated plastic into a mold, then cools and solidifies. The resulting product suits various uses, including making toys or vehicle interiors. Injection molding machines are integral to most plastic manufacturing processes and are ideal for the automotive, medical device, and consumer electronics industries.

According to their application requirements, injection molds are made of steel or aluminum alloy. However, they are usually made of steel. Because it is easy to process while still being strong enough not to deform in the high temperatures of the injection molding cycle, their strength-to-weight ratio means less energy is required to transport them around factories than other metals, meaning the overall cost per unit produced is lower, too!

They are an integral part of most plastic manufacturing processes!

Injection molding machines are an integral part of most plastic manufacturing processes. During injection molding, a heated barrel filled with plastic material is pressed into a mold cavity, where it hardens and takes on the shape of that cavity. Molds can be opened or closed depending on whether you produce individual parts or just one piece at a time.

What kind of product do you want to make before using the injection molding machine? Is it made of one material (such as plastic), or is it a combination of different fabrics? You’ll also need to decide how big your product needs to be if it’s going to fit in someone else’s pocket, and once those decisions have been made, the next step is to choose the type of machine that best suits those needs. Again, we have plenty of options here. It all comes down to your budget constraints and desired level of output quality.

Efficient injection molding machines help produce high-quality products!

Injection molding machines are the most efficient way to produce plastic parts. They are stable and firm, simple and practical, high reliability, easy to operate, process and install, repair and maintain, etc. They can produce high-quality products for many industries. This includes automotive and aerospace parts, medical equipment, and even toys, to name a few. They last a long time without breaking down over time like other materials. It can improve efficiency and control the quality of the production process!

Injection molding machines will gradually grow in the next few years!

Injection molding machines are used in the production of many consumer goods. The injection molding machine market is expected to grow over the next few years, driven by rising demand for plastic products. The global injection molding machine market is divided into type and application segments. This type of part includes single, double, and multi-station. On the other hand, applications include automotive parts, medical devices and equipment, and others such as toys and games. These applications have been further segmented into industries such as aerospace and defense.

The Asia-Pacific region was the largest injection molding machine market last year. Asia Pacific is expected to be the fastest-growing region during the forecast period. The global injection molding machine market is expected to grow from USD 12.38 billion in 2022 to USD 13.14 billion in 2023 at a compound annual growth rate (CAGR) of 6.2%. The Russia-Ukraine war has imposed economic sanctions on several countries, soaring commodity prices and disrupting supply chains, resulting in inflation of goods and services affecting many markets worldwide. The injection molding machine market is expected to reach USD 16.12 billion by 2027 at a CAGR of 5.2%. (Remarks: The data comes from the 2023 Global Market Report on Injection Molding Machines.)

Injection molding machine market dynamics

The injection molding machine market has grown positively over the past few years. The demand for injection molding machines has increased significantly due to their ability to produce high-quality products with high-performance standards and cost-effectiveness. At the same time, the Covid-19 pandemic has hurt key businesses, hindering investment and job growth in new technologies such as robotics. The pandemic has reduced the number of workers in industrial facilities, hampering business. After the epidemic, the demand for medical equipment injection molding products will increase. This is expected to increase the demand for these machines over the forecast period.

The injection molding machine market will be driven by growing demand for healthcare insurance, rapid industrialization in developing countries such as China, India, and Thailand, and increasing demand for plastic molds for electric vehicle production. Asia Pacific is the largest injection molding machine market globally in volume and value, followed by Europe and North America. (Remarks: The data comes from the injection molding machine market.)

Final summary

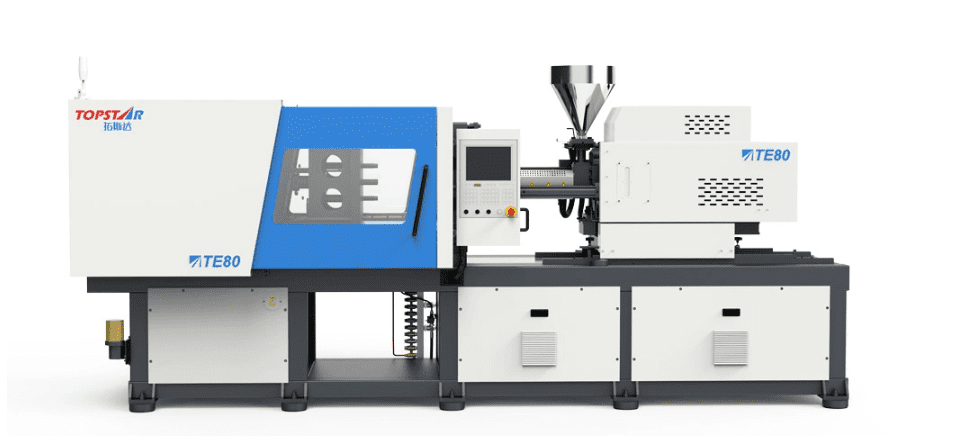

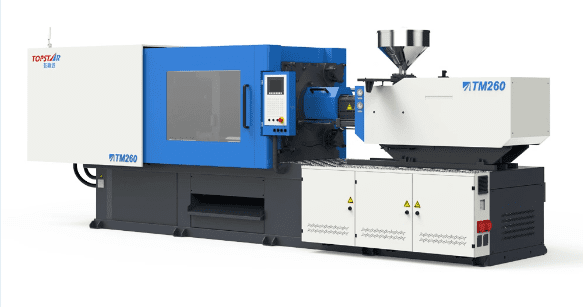

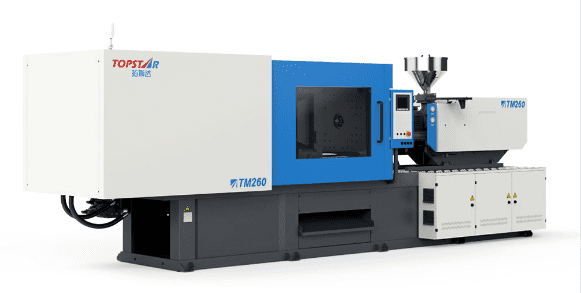

We hope this report can give you a better understanding of the injection molding machine market and industry dynamics. Bringing these points to more people’s attention, it is undeniable that these machines are an integral part of most plastic manufacturing processes, and their demand is expected to grow in the coming years. Our Topstar is to improve professional injection molding machines and industrial equipment for you anytime and anywhere and escort you.

TRENDING POSTS

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- accuracy

- Air Chillers

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC