AFMING presents the GMU-900 CNC machine at CCMT2024!

2024/04/08 By topstar

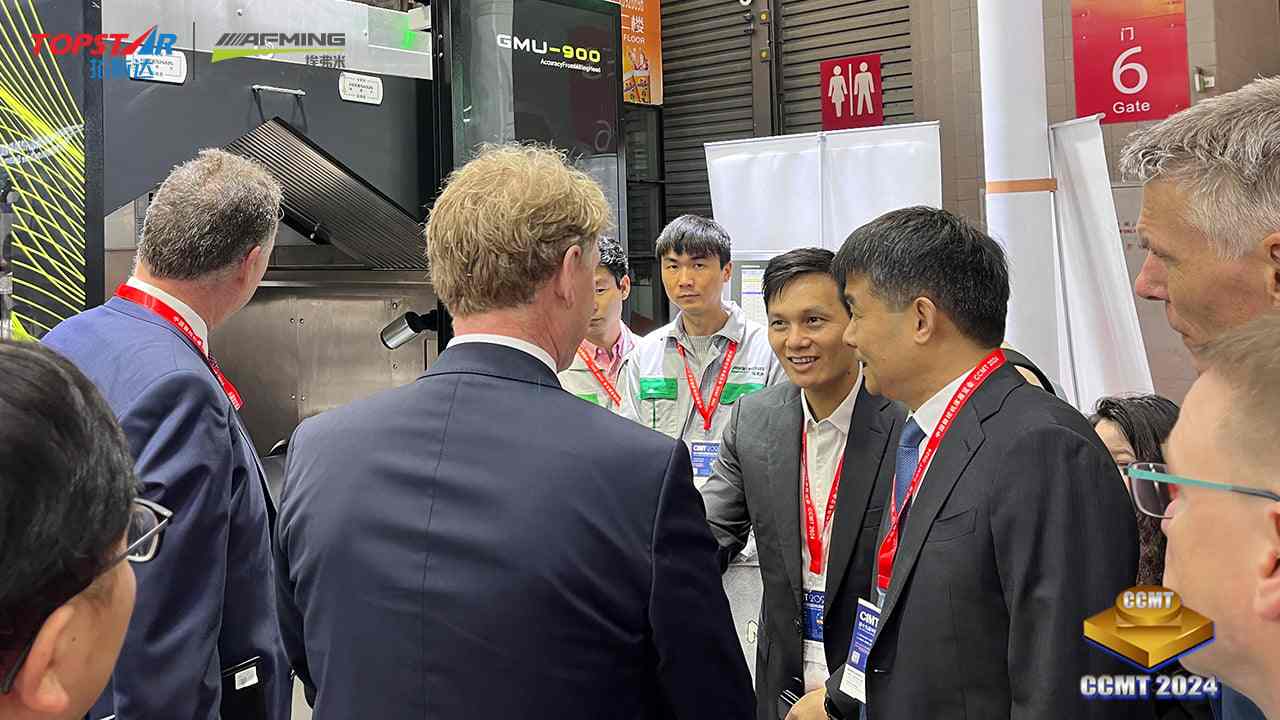

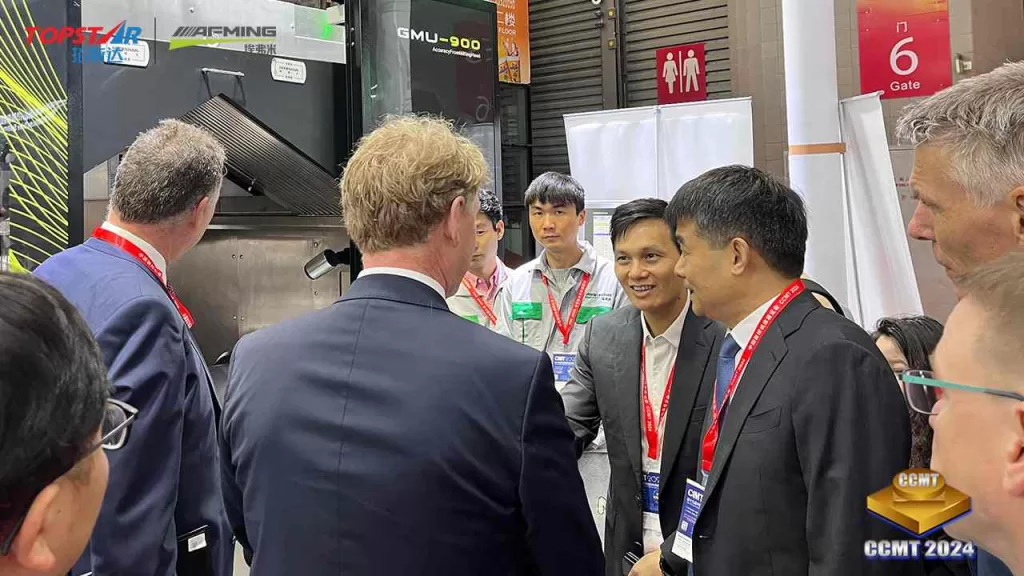

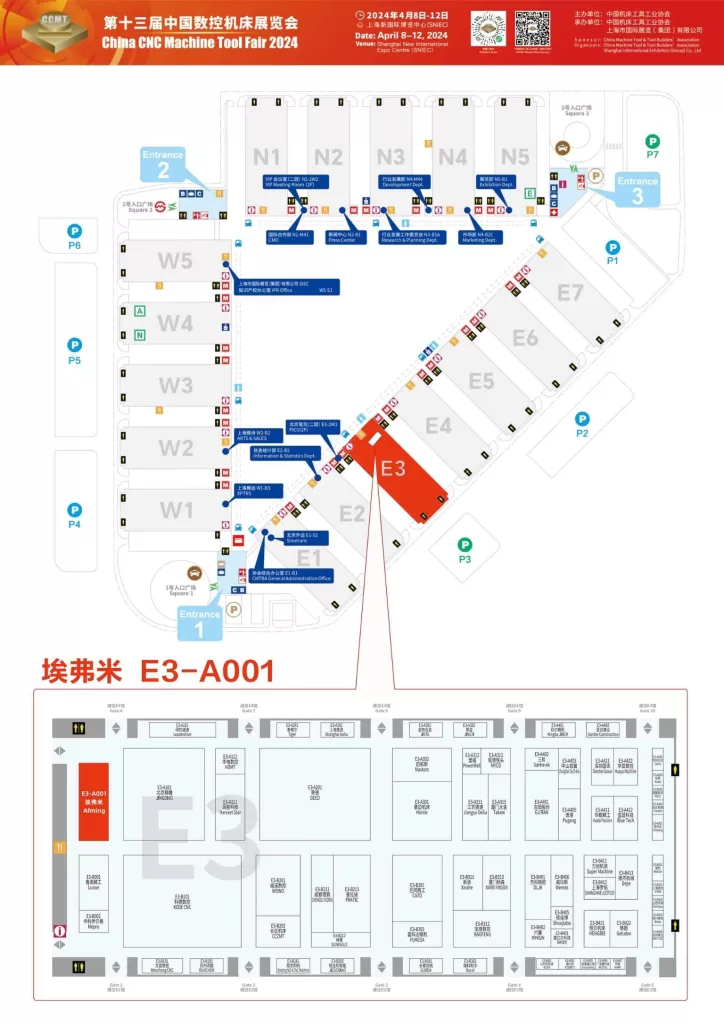

On April 8, the 13th China CNC Machine Tool Show (CCMT2024) officially kicked off at the Shanghai New International Expo Center (Pudong).

AFMING, the holding subsidiary of Topstar, launched one innovative model and two popular models according to the needs of the local industry. In booth E3-A001, these machines with excellent performance and creative design attracted many visitors to stop and look. Many attendees were extremely interested in and recognized AFMING’s products.

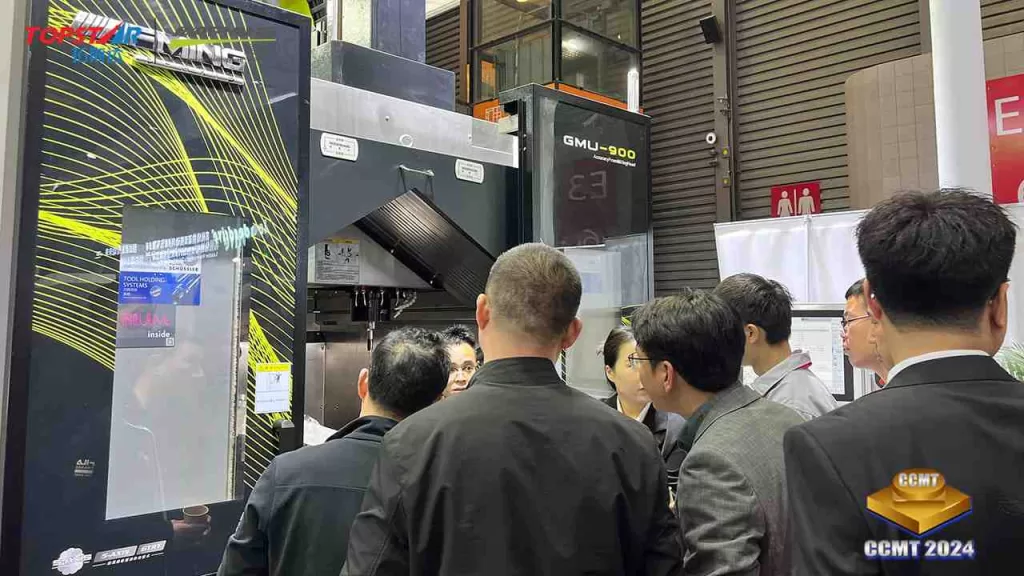

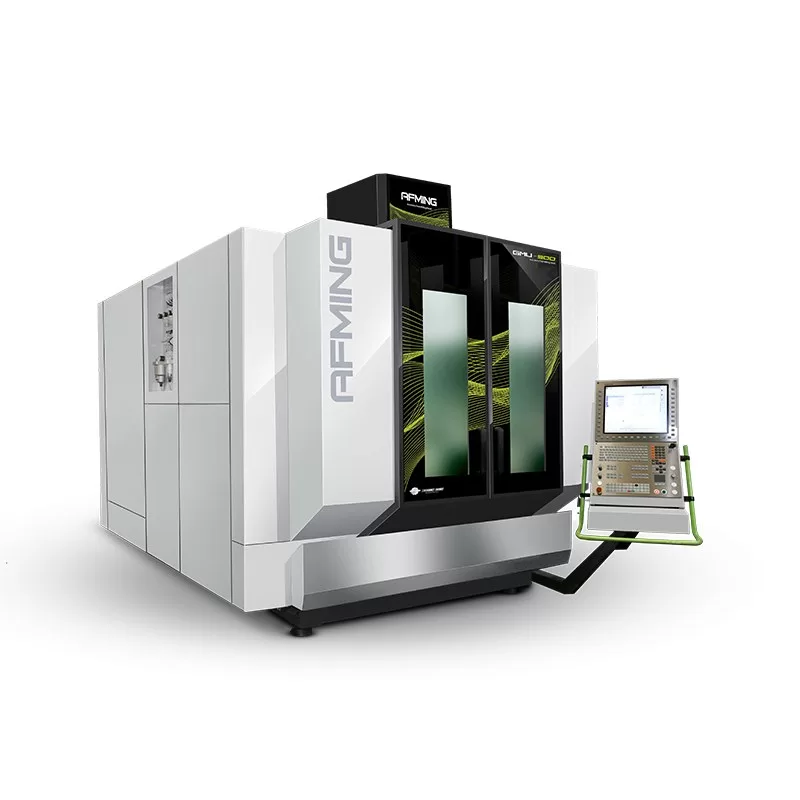

GMU-900 Five-Axis Linkage Machining Center

The GMU-900 five-axis linkage machining center launched by AFMING is designed for the high standard process demand of components in the new energy automobile and civil aviation fields.

The GMU-900 has been fully upgraded with key components such as the rotary table, spindle, and feed system. It not only improves the machine’s machining accuracy and speed but also achieves significant improvements in functionality and economy. The upgraded GMU-900 can easily cope with a wide range of machining situations and also brings a standard of high-quality precision machining to the industry.

Machine Highlights

- GTRT gear-driven rotary table technology

- A-axis torque 4142N.m, C-axis torque 1950N.m

- Positioning accuracy: 8 arc seconds

- Repeat positioning accuracy: 5 arc second

- Maximum load capacity: 1000kgs

In addition to GMU900, AFMING also brings two advanced 5-axis linkage machining centers, GMU-600 and HMU-140P. AFMING demonstrates the solutions at the scene to facilitate the comparison of customers and meet the production needs of different customers in different fields by empowering the major application scenarios.

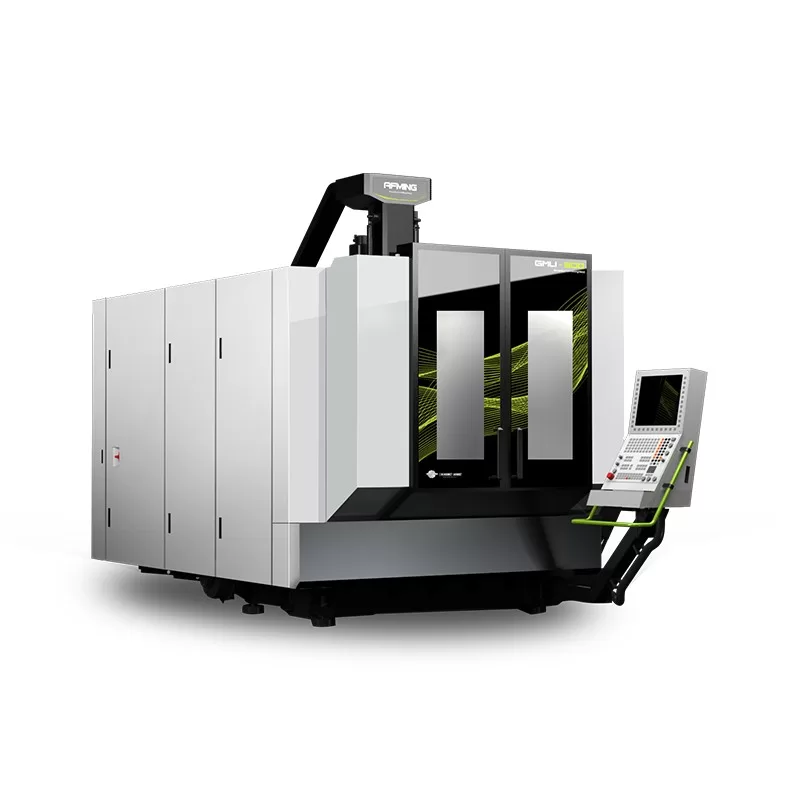

GMU-600 Five-Axis Linkage Machining Center

The machine tool adopts an overhead crane-type structural design, and the bed is a one-piece type, made of high-specification cast iron. X, Y, and Z linear axes run on the bed, the workpiece’s weight will not affect the dynamic performance of the linear axes. The moving parts are far away from the cutting processing area, which effectively reduces the failure rate of the moving parts.

Machine Highlights

- Equipped with the advanced HEIDENHAIN-iTNC640 control system to ensure meticulous control over the machining of complex workpieces.

- The crown block structure ensures dynamic performance remains unaffected by the workpieces’ weight, guaranteeing consistent precision.

- The A/C axes are supported on both walls for solid support stiffness.

- Achieved multi-face milling easily by clamping the workpiece once, drastically reducing machining time.

- Trusted across automotive, mold, and medical industries for its exceptional performance.

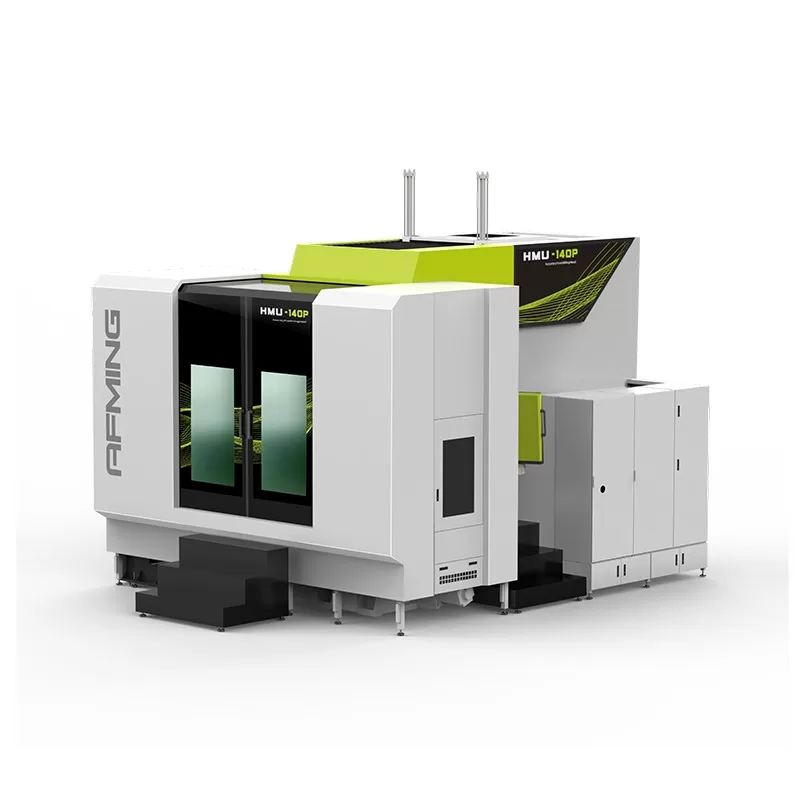

HMU-140P Five-Axis Linkage Machining Center

The main users of HMU-140P are civil aviation and new energy automobiles. Dynamically optimized by FEA, it is equipped with self-developed high rigidity and high torque gear rotary table and single pendulum milling head. The whole machine frame has excellent rigidity and sensitive movement. It can easily cope with the requirements of high-efficiency and high-precision machining of various material parts.

Machine Highlights

- Spindle head length of 850mm, suitable for in-depth machining of shell cavities.

- The max. torque of the A-axis is equipped with the original gear drive structure, and the rated torque reaches 6500Nm.

- Three-axis linear displacement speeds of 40 m/min and 60 m/min.

- Acceleration in three axes up to 0.6G.

CCMT will continue to be in full swing until April 12, and the excitement on site will continue to intensify. We sincerely invite you to visit our booth E3-A001 to discuss the latest technology and solutions for precision machining.

Topstar’s corporate mission is to “make industrial manufacturing better”. Topstar adheres to the vision of “making industrial manufacturing better” and creates an intelligent hardware platform driven by core technologies through intelligent equipment centered on industrial robots, injection molding machines, and five-axis CNC machines, as well as three core technologies of control, servo, and vision, to provide manufacturing enterprises with an overall intelligent factory solution.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/04/08

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/04/08

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/04/08

- Topstar Special | National Science and Technology Workers Day 2024/04/08

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC