Global Market Analysis of Injection Robot Manufacturer

2023/10/23 By Topstar

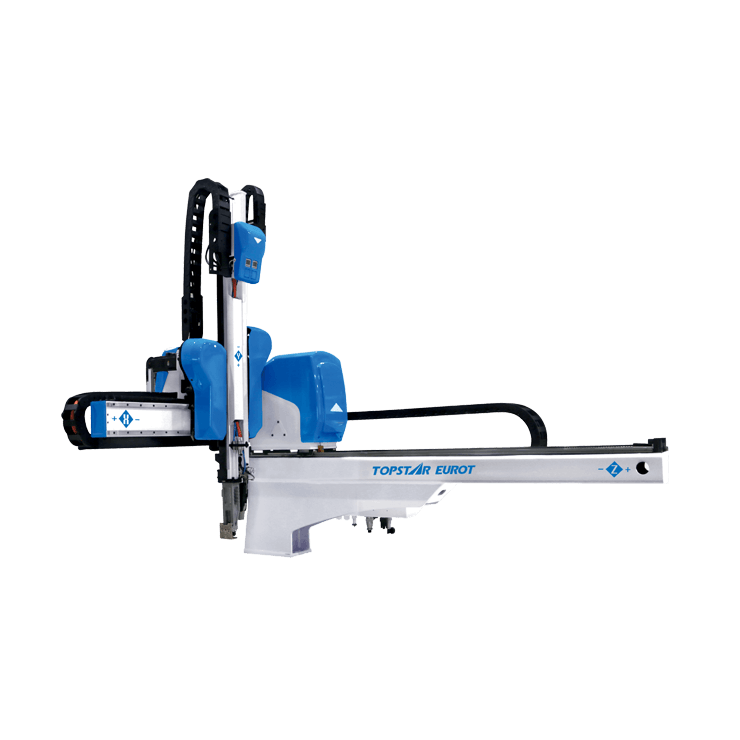

As people demand for injection molding increases, the need for the injection robot manufacturer market continues to grow significantly. The global manufacturing landscape increasingly recognizes the importance of streamlined and cost-effective production processes. The automotive, electronics, and other industries rely on injection robots to meet growing production needs. This surge in demand is the driving force behind the significant growth of the injection molding robot manufacturing market. This article provides a comprehensive global market analysis, exploring their roles, market trends, and key players.

Injection robots’ horizons continue to expand!

The global demand for injection robots is growing due to the need for streamlined and cost-effective manufacturing processes. Industries such as automotive, electronics, medical devices, and consumer products rely on injection robots to meet their production needs. This surge in demand has spurred the growth of the injection robot manufacturing market. Market leaders include many established players. These manufacturers are known for their innovative technology, precision, and adaptability. They offer a wide range of robotic solutions to meet the unique needs of different industries.

Injection Robot Manufacturer Regional Market Dynamics

The global market for injection robot manufacturers is not uniform; it is affected by regional dynamics. The Asia-Pacific region, home to major manufacturing hubs, is leading the way in adopting injection robots.. North America and Europe also have a significant presence in this market, driven by industries requiring precision and automation. Their regional dynamics are crucial to understanding global patterns. The Asia-Pacific region, with its concentration of major manufacturing centers, has been at the forefront of adopting injection robots. This growth is driven by the region’s strong presence in the automotive, electronics, and consumer goods industries, which require precise, efficient, and high-speed production.

Market Trends: Automation and Collaboration

Two significant trends in the injection robot manufacturing market are automation and collaboration. Automation technology continues to evolve, allowing robots to handle more complex tasks. Collaborative robots (cobots) are also gaining traction, especially in industries where human-machine collaboration is crucial. The injection robot manufacturing market has two prominent trends shaping the industry’s future. First, automation continues to evolve, enabling robots to take on increasingly complex tasks. This trend is evident in the capabilities of modern injection robots, which can handle complex and high-precision operations.

Sustainability and Environmental Practices

It’s a topic that continues to be discussed, and sustainability has become a focus for injection robot manufacturers and their customers. Manufacturers are implementing environmentally friendly practices into their production processes, with their robots designed to reduce waste, improve energy efficiency, and enhance overall sustainability. They are not just about innovation and efficiency; They also embrace sustainability. Manufacturers are increasingly adopting environmentally friendly practices in their production processes, bringing sustainability into focus. Their robots are designed to minimize waste, increase energy efficiency, and contribute to environmental sustainability.

Market Challenges of Injection Robot Manufacturing Market

While the market is growing, challenges also exist. Cost remains a concern for many companies, and finding the right balance between investment and ROI is critical. Integration with existing production systems can also be challenging, and manufacturers are working hard to provide seamless solutions. Despite the growth, the injection robot manufacturing market still faces particular challenges. Cost is a significant concern for many companies, as investing in a high-quality injection robot can be a substantial financial commitment. An essential business consideration is to strike the right balance between investment and return on investment (ROI).

One final summary

The global market for injection robot manufacturers is booming. The market will grow and transform as industries worldwide adopt injection robots for their manufacturing needs. As a leader in the injection molding manufacturing industry, Topstar will continue to innovate and maintain its mission of “making industrial manufacturing better” to serve the audience.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/10/23

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/10/23

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/10/23

- Topstar Special | National Science and Technology Workers Day 2023/10/23

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC