Highly Efficient And Excellent GMU-600 5-Axis Machining Center Will Be Available Soon

2022/04/07 By topstar

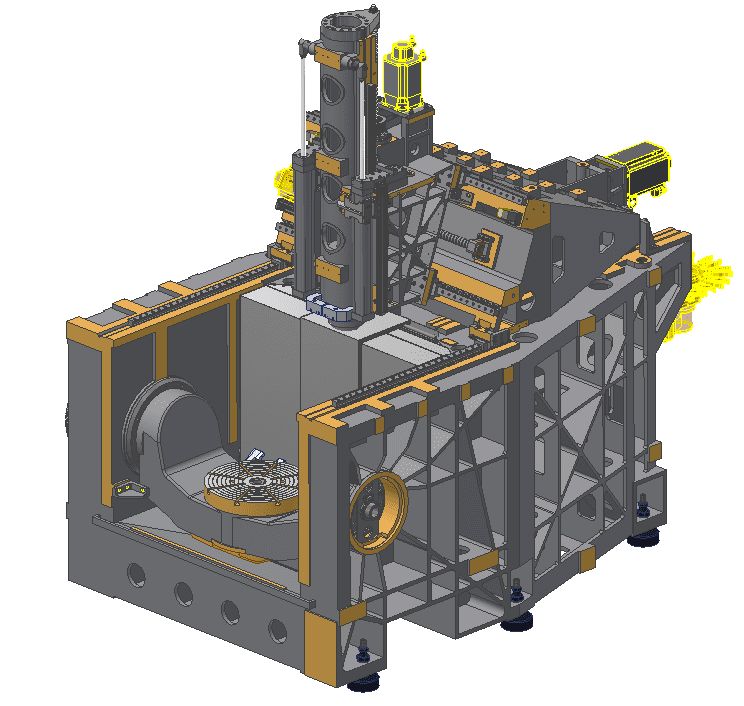

GMU-600 5-Axis Machining Center

The 5-axis machining center is high-tech and high precision, specifically for processing complex surfaces. In the scientific research, precision instruments, and high-precision medical equipment. And other industries have a significant impact.

With the rapid development of China’s national economy and the transformation and upgrading of the manufacturing industry. The five-axis CNC machine tools, as a representative of the manufacturing capacity of complex and high-precision equipment, are increasingly in demand.

To meet the high output and high-efficiency production needs of domestic manufacturing enterprises. AFM, a subsidiary of Topstar Holdings, combines advanced international technology. A new independently developed five-axis machining center GMU-600 has been launched.

Characteristics of CNC machine tools

High efficiency, rigidity, dynamics, and precision characterize the CNC machine. It is suitable for manufacturing complex parts for automobiles, industrial equipment, mold, and other industries. Among them, high rigidity is ideal for machining thin-walled parts. High dynamic is suitable for machining complex surfaces. High precision is perfect for machining precision parts.

01 Highly Rigid Bed Structure

The GMU-600 machine is designed with an overhead crane structure and an integral bed. X/Y/Z linear axes run on the machine without the workpiece’s weight, adversely affecting the linear axes’ dynamic performance.

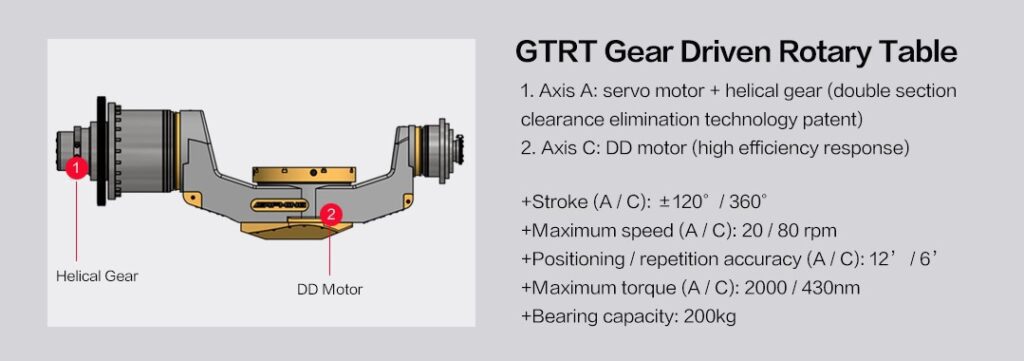

02 Highly Rigid And Efficient Cradle Turntable

The A-axis of the GMU-600 rotary table adopts European high-end mechanical transmission GTRT technology, which realizes more robust torque output, rigidity, and stability than conventional turntable drive. The C-axis is driven by a DD motor, showing higher dynamic response and excellent slewing accuracy.

03 Spindle

16000rpm/20000rpm electric spindle adopts long-lasting grease and oil-air lubrication cooling technology. The front end of the main shaft adopts a water discharge ring combined with labyrinth and air curtain sealing technology. Combined with an innovative cooling runner, it can effectively inhibit the thermal elongation of the spindle. Ensure the operational performance, accuracy, and service life of the spindle.

04 Industry Application

GMU-600 five-axis machining center applies to automobiles, industrial equipment, mold, and other industries.

As one of the representative enterprises in the field of intelligent manufacturing in China, Topstar has always adhered to the corporate mission of “making industrial manufacturing better.” In industrial robots, injection molding machine products continue to develop, and in 2021 successfully held AFMING, completing the layout of the CNC machine tools business line. Broaden the CNC machine tool product categories to help China’s high-end equipment manufacturing industry with high-quality development.

AFM, a subsidiary of Topstar, has formed a series of core technologies and core products in five-axis CNC machine tools and vital functional components through independent research and development to achieve independent control of critical technologies. The company’s products include five-axis linkage machine tools, graphite machining centers, high-speed machining centers, and grinders. And CNC machine tools in other industries such as automobile, medical, precision mold, and mechanical parts processing.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/04/07

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/04/07

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/04/07

- Topstar Special | National Science and Technology Workers Day 2022/04/07

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC