Molding Injection Machine: Guide to Learn its Features

2021/12/16 By Topstar

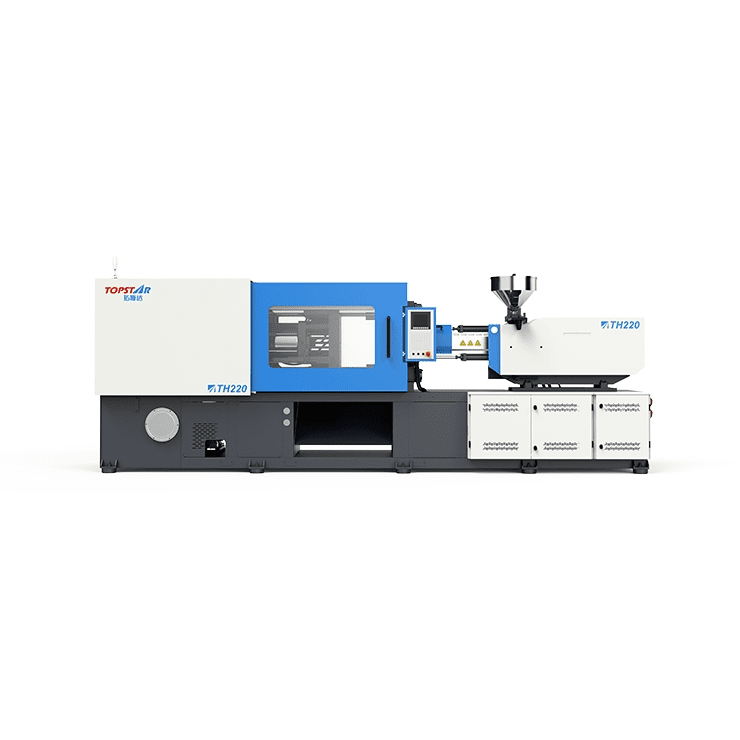

Energy saving molding injection machine

Energy-saving molding injection machine is special machines, the purpose of which is as follows: they cast plastic mass heated to a certain temperature. Injection molding of thermoplastic materials makes it possible to create various products from polymers.

Design of energy saving injection molding machine

In order to implement all of the above, the injection molding machine has designed as follows:

- Firstly, a special electric motor with a servo drive picks up the required amount of material

- Secondly, a hydraulic drive with a hydraulic accumulator ensures the maximum injection rate of liquid plastic

The first makes it possible to implement several operations at once. Moreover, it significantly reduces the time spent on the molding cycle. In addition, the AC servo motor makes the molding injection machine stable at all speeds.

In turn, energy-saving will be there due to the fact that pumping systems with a servo drive have in their design a hydraulic drive for an electric motor and a hydraulic accumulator..

How to distinguish molding injection machine?

The quality of the product: Injection of plastics through the use of our technology results in products of the highest quality. Extremely high repeatability is ensured as injection pressure and speed are tightly controlled thanks to a special feedback function.

In addition, the response of the hydraulic system is accelerated, which reduces the amount of time required for switching and increases the productivity of the machine.

Reliability and durability: All equipment is able to cope with its function without a single failure for an extremely long time. You can forget about the problems associated with the need for repair or replacement.

Energy saving molding injection machine

A special energy-saving hydraulic drive minimizes all energy costs. Molding injection machine tools differ among themselves not only in productivity, accuracy class, but also in other characteristics that enable every entrepreneur, both small and large, to organize a full-fledged production of their products.

You can produce any product and absolutely any shape and size. This became possible due to the presence of a wide variety of molds and equipment for their manufacture.

One of the leaders among European machines for the manufacture of polymer products is equipment under the Top star brand. It is a well-deserved world leader in the development and production of automatic and semi-automatic equipment for the production of products from polymer-containing materials.

Advantages of Top star molding injection machine

As a world leader in the production of molding injection machine for the production of polymer products, the company has endowed its machines with the following qualities that make it out of competition with brands from other companies:

- Easy setup and manageability – the interface of all types of equipment is so simple that even a beginner who sees a machine of this level for the first time can handle it. The developers competently approached the implementation of each control body and achieved excellent results, which affected productivity and reliability.

- All Top star machines have an increased class of reliability and durability, which means that there are no unnecessary material costs for repairs that simply will not be necessary.

- Flexibility – all equipment, without exception, we can quickly readjust the production of any product, regardless of its complexity, configuration and size. The work area is large enough to accommodate molds for large plastic products.

- The company specializes in all types of control systems; therefore it has a higher class of reliability and durability regarding molding injection machine, but only with qualified service.

The equipment is designed for people of all levels of development. It still requires knowledge of some points to operate and maintain it.

Moreover, it is important to study the aspects of machine control and adjustment work. It is also useful to follow all actions strictly according to the instructions.

What do you know about assortment of equipment?

The European company has taken a leading position, therefore it can boast of a fairly wide range of equipment of various levels:

- TM Series Toggle Injection Molding Machine(90T-470T)

- Press Type Injection Molding Machine(130T-1400T)

- Electric Injection Molding Machine(80T-230T)

The presented list of machines for molding plastic into a mold makes it possible to manufacture products. Moreover, it needs a specific volume of plastic up to 433 cm. At the same time, the closing force can reach 430 tons. It indicates the possibility of producing absolutely any parts, both in size and shape.

What are the reasons to choose Top star?

Choosing molding injection machine from Top star for your enterprise, you will provide yourself with really high-quality equipment. It will regularly perform its functions. Moreover, it provides you with no less high-quality products from all types of polymer.

The possibility of quick changeover to the production of new plastic products will give you a huge advantage over your competitors.

European equipment – high quality, practical and durable – this is a fact, but this also makes it the most expensive. The fact is that machines and robots from this brand are designed by the best engineers in the field of robotics and the production of plastic products.

An injection molding machine is a single unit. It can produce any plastic product, but to fully automate the process. You will also need to purchase additional equipment for loading raw material, unloading finished products and changing molds.

Why our molding injection machine better option for you?

A natural question will arise: why is it worth ordering molding injection machine from us? Here is a far from complete list of our advantages:

Firstly, practicality, quality: All presented products are made of high quality materials and in accordance with all existing norms and standards. As mentioned above, all our products are really durable and capable. These are of fully and exhaustively responding to any requests over an extremely long period of time.

Secondly, low prices: The cost of our services is extremely client-oriented, that is why it is minimized and extremely democratic. In addition, the low energy consumption of the injection molding machines leads to savings in the future.

Thirdly, interaction with the client: We always take into account every client’s request, further implementing it. Working with us, you will only get a pleasant impression of our service.

Summary

We can equip the presented line of injection molding machines with additional equipment. It is a hydraulic rod and a robot for extracting the finished product from the mold. Moreover, it is loading a new mold and loading the next portion of raw materials in the form of granules or flakes into the hopper.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2021/12/16

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2021/12/16

- Star Case | Topstar helps Santong upgrade its intelligent plant 2021/12/16

- Topstar Special | National Science and Technology Workers Day 2021/12/16

HOT TOPIC

- .ervo motor-driven linear robots

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 2

- 21

- 23

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 5-axis CNC machine

- 62

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar