What is plastics injection molding machine? Best Guide 2022

2022/01/31 By Topstar

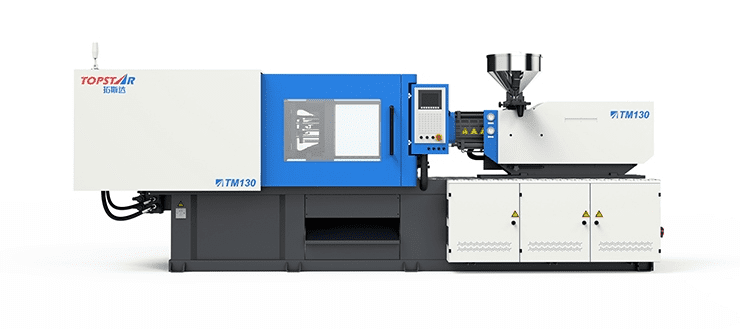

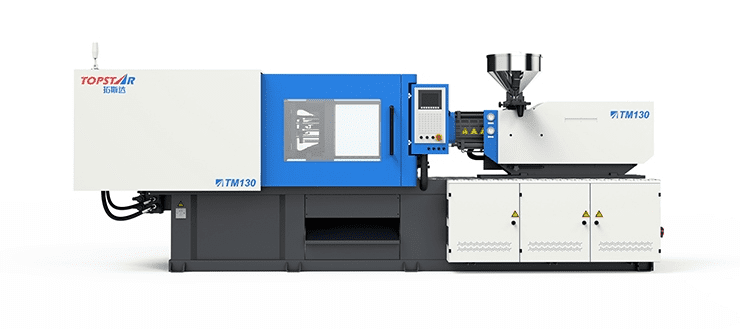

A plastic injection molding machine is also known as a forming machine, injection molding machine, or glue machine. They are commonly good in injection molding technology lines.

The plastic injection machine keeps the mold closed while pushing the molten plastic by injection pressure into the mold core. It fills the mold cavity and opens the mold after the product cools. The product will then be pushed out through the core system.

Different Brands of pressure molding machine

There are many types of plastic injection machines from different brands on the market. These are classified according to the pressure of the device. The plastic mold maker will choose the suitable machine based on the machine’s parameters. Please continue to read the following content to learn an overview of plastic injection machines!

Plastic injection molding machine structure

The plastic injection molding machine consists of 2 main components: the mold clamping and the plastic injection.

Mold clamping part: includes fixed mold clamp part and movable mold clamp part. The fixed mold clamp has a clamping function that holds the mold in place so that the mold positions accurately. Thanks to the mold’s locating ring and the machine’s positioning hole. The movable die clamp is suitable for clamping the movable side mold half.

This part moves in a reciprocating direction parallel to the opening and closing direction of the mold. Open and close the mold during the plastic injection molding machine cycle, and arrange with a push rod to help act on the pin ejection plate, pushing the product out.

The plastic injection part

The plastic injection part is the part that uses temperature to convert the plastic fuel from a solid to a liquid form. It pushes the molten plastic into the mold by forcing pressure through the screw system and the nozzle.

Besides these two main parts, the plastic injection machine also adds a cooling system, a robot, or other support systems.

How are plastic injection machines classified?

Plastic injection molding machines are classified into two main types: Horizontal injection molding machinery and Vertical injection molding machinery. These two machines operate on the same principle. However, in terms of layout, there is a difference between them. Vertical machines take up space in height, and horizontal machines take up space in width.

Horizontal and vertical plastic injection machine

Horizontal plastic injection machines are more commonly good because they are cheaper, safer, and more versatile than vertical ones. Vertical injection molding machines are often good in companies. They make insert molds and change cores directly on the injection molding machine because it brings convenience to the operator.

Working principle of plastic injection molding machine

This Plastic injection molding machine works like a syringe that we are good to see. Liquid plastic is injected to fill the mold cavity, and the cooling system will cool down to take the product out.

First, the material is put into the hopper, melted by heating rods at a suitable temperature, and converted to liquid. Then, the liquid plastic is led forward by the screw (rotation); the screw also moves back to create a space in front of the nozzle for the plastic to overflow.

Thanks to the thrust of the screw (not rotating), the molten plastic is injected into the mold.

The cooling system for the shape of the product

After the mold cavity is filled with plastic, the cooling system of the plastic injection molding machine will convert the plastic from liquid to solid to shape the product in the mold cavity. Next, the movable mold clamp opens the mold to a predetermined distance, pushing the product out by the back of the press, which exerts a force on the ejector pin system of the mold at a predetermined length.

Famous plastic injection machine brands in the market.

Plastic injection molding machine brands are mainly manufactured in countries with the world’s top injection molding technology level.

Famous plastic injection companies prefer machines from the US, Japan, Germany, or Australia because their products have a long life and high stability. Plastic injection molding machines from Chinese brands are also viral thanks to their more affordable prices.

However, the product’s life is not high, there is a lack of stability, and the electrical system is short-lived. The designer must have basic knowledge of plastic injection molding machines to design a plastic mold.

Where to buy a plastic injection machine at an affordable price?

TopStar Machine hopes that you have had an overview of this device through this article. Moreover, if you are still wondering where to buy a reputable plastic injection machine at an affordable price, TopStar Plastic injection molding machine is the right choice.

With many years of experience in the technical field, we have built a brand that many people know.

Ensuring product quality at a competitive price

Firstly, when buying at our facility, the unit always commits to ensuring product quality and the most competitive price in the market. Our staff will also enthusiastically advise customers to choose the most suitable product. Coming to us, customers will enjoy many good benefits and great experiences.

Classification of Plastic injection molding machine:

Plastic Extrusion Machine

It is an extrusion machine. The form of the plastic extrusion machine can be continuous or semi-continuous.

However, the Extrusion Process has the same Main Operating Principle as Plastic Injection Molding Machine. However, the design of the plastic mold is different when the extruded plastic product is a continuous or interrupted form of a Tube or long rod.

Popular Plastic injection machine

Is to use plastic injection mold good? Usually, plastic injection molds shape popular products in daily life and consumption.

Plastic blow molding machine:

Most commonly, the products below are inside, including Bottles, Bottles, and Tanks…This Plastic injection molding machine uses Compressed Air to blow the Inflated Plastic into the mold.

Plastic laminating machine:

In conclusion, these machines use sheet molds, extrude plastic sheets, and conduct hot rolling. For this product, in addition to the quality requirements of the plastic and the mold, it is necessary to undergo the rolling and shaping stage for the plastic sheets.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/01/31

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/01/31

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/01/31

- Topstar Special | National Science and Technology Workers Day 2022/01/31

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC