Things you should know about dryer cabinet

2022/06/27 By 兰兹

Dryer Cabinet:

A dryer cabinet is used to dry raw polymer resources, mainly when working with small quantities of different components or polymers for testing. After tempering, it could be used in polymer molding to improve toughness, remove tension, and improve the quality of plastic products. It can also preheat or dry electronic, electroplating, pharmaceutical, paint, printing, and other products like pollen, tea, or garlic.

If you operate in the plastics processing sector, you know that resin can start collecting moisture from the environment during the procedures.

When do plastics get wet?

Some plastic resins, whether you believe it or not, become wet, not just on the surface, but down deep at the molecular scale. A few plastic resins have polarity, attracting water and forming molecular bonds with the polymer. These are referred to as hygroscopic resins. Non-hygroscopic resins are plastic polymers that do not collect moisture and only get moist on the surface. Even minor moisture levels in hygroscopic resins, measurable with only instruments, can cause quality issues when polymer resins are molded into parts.

How is plastic resin dried?

Dryers with Hot Air or Dryer cabinets are the most common resin dryers. Such dryers draw airflow from the external environment, heat it using a heat source, and feed it through a plastic resin-filled hopper. The humidity from the plastic resin is picked up by the hot air and carried out of the bin. Hot air dryers are typically used for non-hygroscopic materials that accumulate humidity. Unfortunately, the surrounding stand-alone cannot remove all moisture from resins. Once you reach this stage, consider alternate drying options, such as cabinet dryers.

What Is the Function of Drying?

Materials have occasionally been exposed to damp screening or had fluid added to them to facilitate processing. The following stage goes through drying or dewatering to return the material to its original condition or develop a particular form for the finished product. Furthermore, if a residual waste must be burnt, drying might assist in preparing the item for suitable disposal. Drying is frequently the last stage in manufacturing before selling, packing, or storing a commodity. Adjusting moisture in solid materials is essential in chemical treatment because it reduces shipping and storage costs by reducing excessive liquid volume in a substance.

What Is the Process of Cabinet Drying?

Although there are numerous varieties of cabinet dryers, they all function in the same way. Cabinet dryers differ from typical plastic dryers because they use hot, dry airflow to remove moisture from plastic resin instead of ambient air. Air flows in a sealed process in cabinet drying systems, preventing air from departing the top of the bucket and entering the ambient air.

Dryer cabinet products are dehydrated to move onto stainless steel trays. Process air will flow to the hot wire throughout the operation and can be warmed to the necessary temperature.

What Are the Benefits of a Cabinet Dryer?

Compared with other forms of drying equipment, drying cabinets have several advantages, including higher efficiency, lower cost, and cutting-edge technology.

More Efficiency:

Cabinet drying boosts efficiency in your facilities while making your organization more energy efficient. Because these drying systems provide constant, closed-loop drying, the dehumidifier can absorb water more consistently, allowing the resin to move quickly from process to process. Most of these dryers include several critical components that make them a more energy-efficient option over time. Indeed, certain technologies featured in cabinet dryers are said to reduce energy consumption by 25 -30 %.

Cost-effectiveness:

Cabinet dryers are more cost-helpful in the long term. You will identify this right after the first usage. These dryers assist in reducing other expenditures and enhancing your facility’s overall effectiveness, which can help you generate revenue and reduce operating costs. This drying technology, for example. The tightly closed chamber or system requires little maintenance and reduces contamination.

Greater productivity with an enclosed system:

Dryer cabinets are used to eliminate moisture from non-hygroscopic materials effectively and to preheat them before processing. When the product is placed in a cold area, this preheating is especially effective when processing in many humid and hot environments. They are typically made of a well-insulated feeder with a connected blower and heater. Wet air is dissipated into the atmosphere when hot air is blasted through the material particles. These dryers are made up of an enclosed system that contains materials that should be dried out. They lower the relative humidity, allowing moisture to evaporate more quickly. They are frequently used to reduce the moisture level of delicate materials.

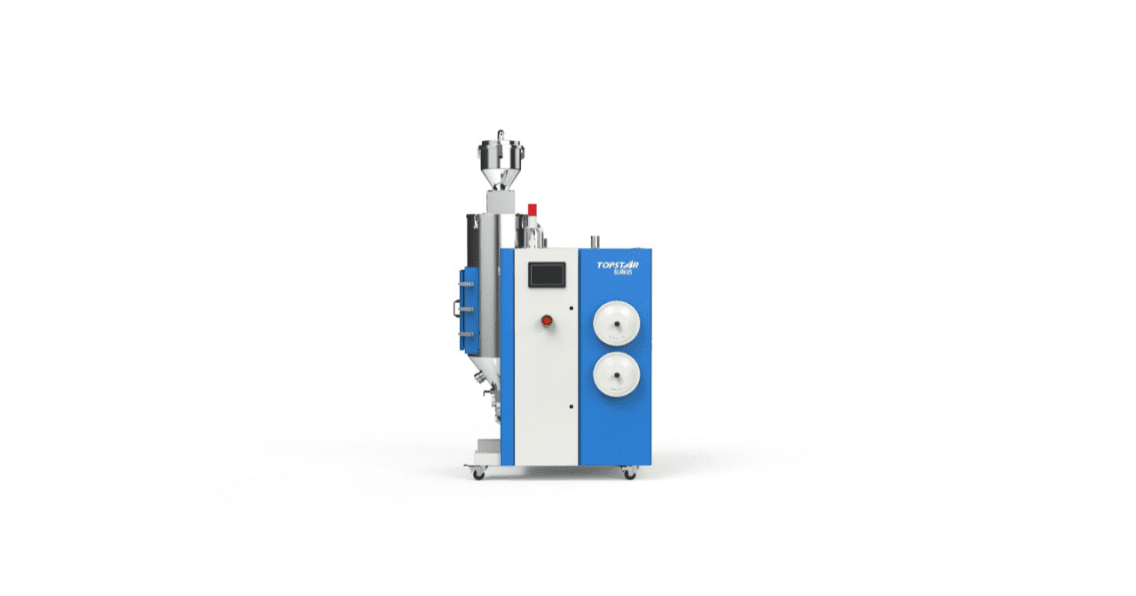

Why should you choose TOPSTAR for your dryer cabinet?

A dryer cabinet is used to dry polymer or plastic raw materials, mainly when dealing with small amounts of varied materials or polymers for testing. After tempering, they can improve toughness, reduce tension, and improve the quality of plastic goods.

Top-star’s innovative vital air temperature and duct system design ensures uniform internal temperature distribution. Our dryer cabinet comes with a stainless steel hood and a flowing hot air recycling system that is energy-efficient, long-lasting, and appropriate for drying a variety of plastics. They are equipped with an automatic timing device; any moment can be set in advance to be dry. The cabinet dryer has distinct characteristics, and the heat can be adjusted to provide an equal drying process. In addition, new cabinet dryers now have wind-isolating doors that can maintain a consistent temperature within, reducing energy usage. Our cabinet dryer’s stainless trays and linear do not contaminate the materials. It is simple to use, and overheating protection can prevent excessive drying.

TRENDING POSTS

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- accuracy

- Air Chillers

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC