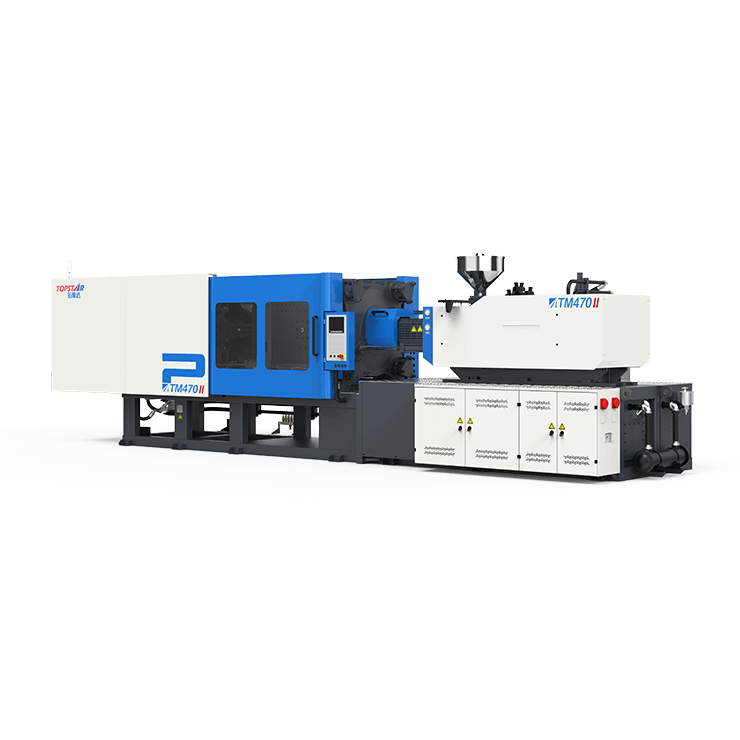

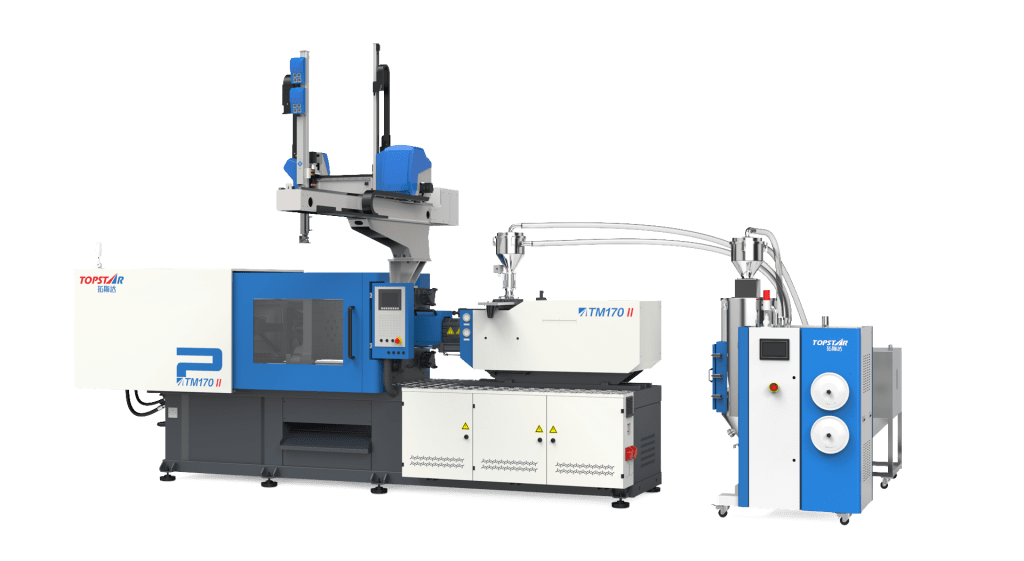

Topstar’s toggle clamp injection molding machine

2024/01/22 By Topstar

Among Topstar’s injection molding machine series, the toggle clamp injection molding machine type is a universal one. Their high degree of integration, precision, and efficiency are suitable for injection molding small and medium-sized plastic products in electronics, optoelectronics, and 3C home appliances. In the article, we will introduce the products of the toggle clamp injection molding machine in more detail and a series of features and innovative technologies.

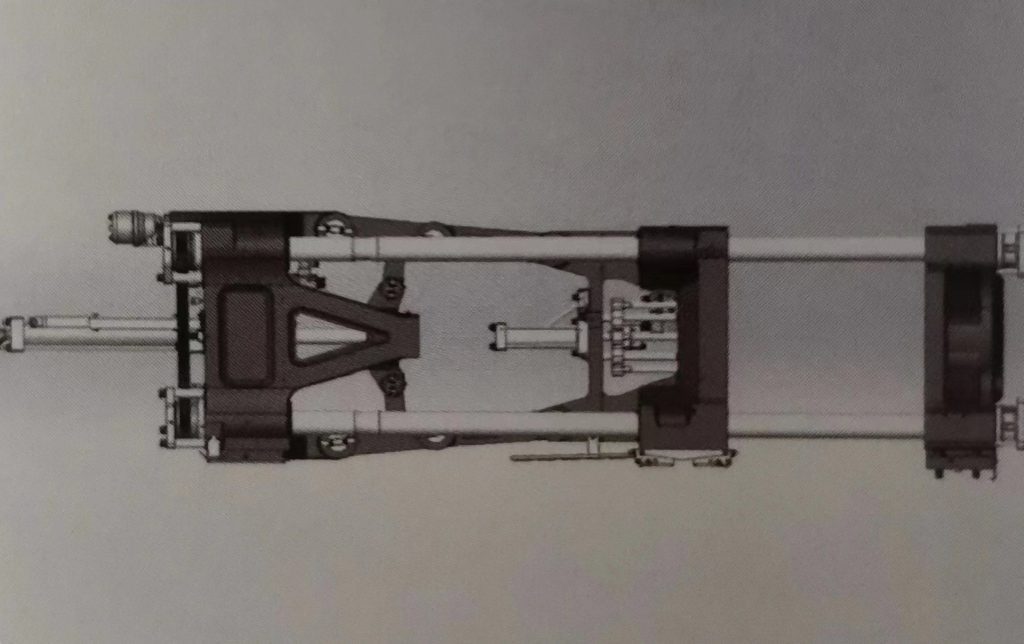

Product accessories for toggle clamp injection molding machine

They come standard with KEBAcontroller, PHASE motor, Delta driver, and our self-developed control program. As standard, the injection part equips an electroplating screw, and the temperature control of the discharge port enhances the survival efficiency, making it suitable for a broader range of rubber materials. We use oblique double-injection cylinders and linear guides to stabilize the glue injection. The Pre-plasticizing adopts proportional back pressure control, which realizes multi-stage rear pressure settings, making the operation more accessible and precise.

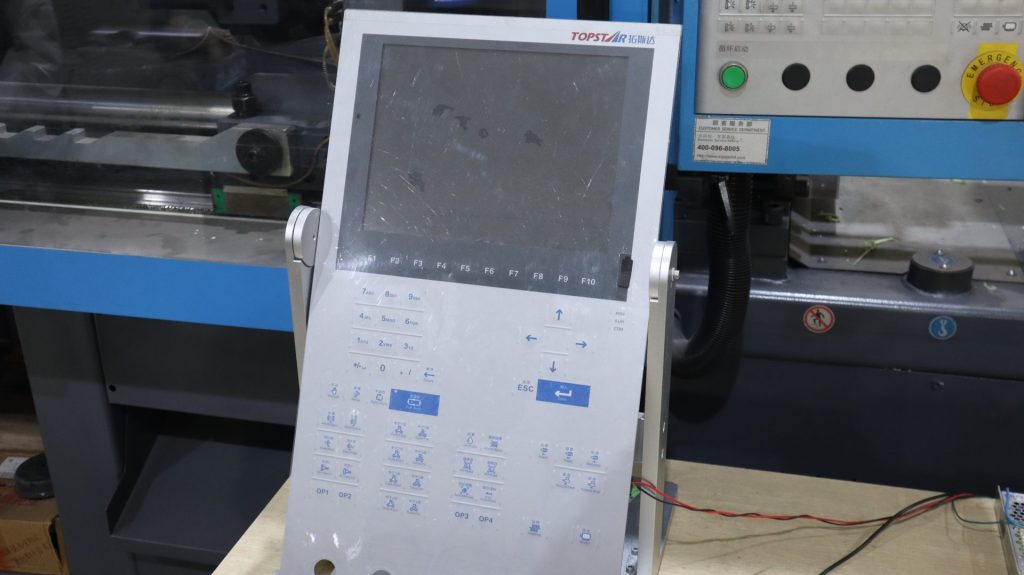

Control system of toggle clamp injection molding machine

Their control systems usually use electro-hydraulic servo control, in which the servo power is increased by 20% to make it faster and more efficient. The injection speed is increased by 20%, and the injection speed is increased by 20% for better performance when molding complex structures and specific materials. In addition, the melting speed is increased by 10%, shortening the injection molding cycle. Ensure the uniformity of molded products and increase overall efficiency by 15%. The control system adjusts clamping force dynamically, monitoring mold size, material properties, and process conditions in each cycle. This adaptability ensures optimal clamping force for different molds and materials, helping to improve product quality and reduce production defects.

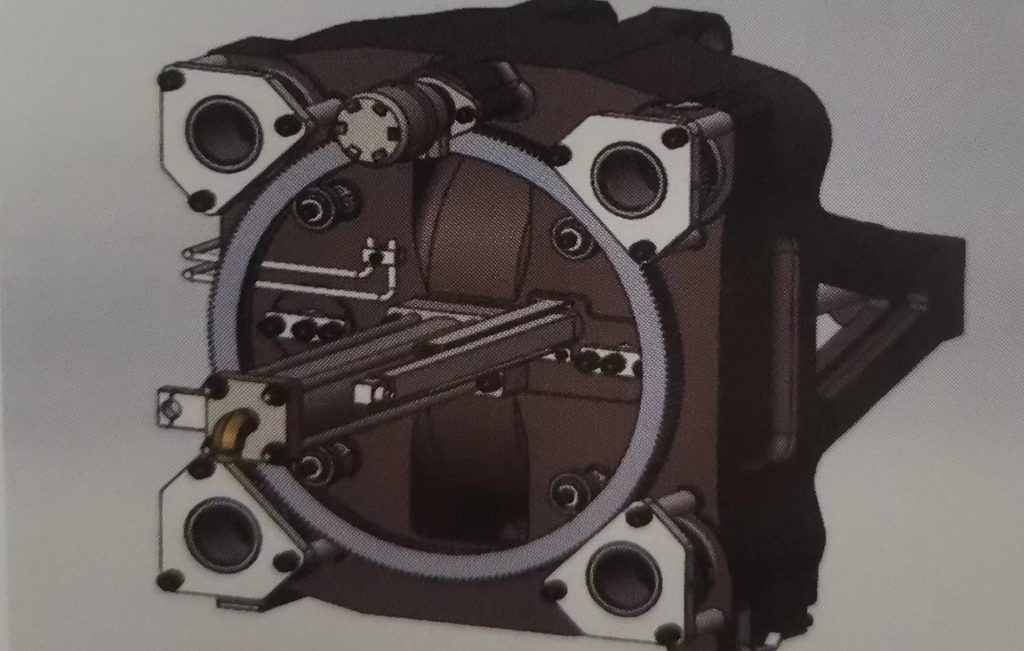

The clamping unit of the toggle clamp injection molding machine

A “toggle clamp” means a hinged or articulated connection allowing flexible movement. This feature enables the mold to open and close smoothly to accommodate a variety of mold shapes and sizes. The hinge ensures correct alignment of the mold halves during closing, minimizing the risk of defects in the molded part. The mold clamping part of the toggle clamp injection molding machine adopts a new inclined machine layout, which can achieve ultra-long stroke mold opening, and the mold opening position accuracy is <±1mm, making the template movement fast and stable. In addition, the new mold adjustment mechanism can realize automatic and precise mold adjustment with one click. They increase the ejection pin thrust by 20%, which is more conducive to the demoulding of connectors and plug-in products.

Versatility

The versatility of toggle clamp injection molding machines enables the processing various materials, including thermoplastics, thermosets, elastomers, and even certain types of metal powders. This adaptability makes these machines suitable for multiple industries, from automotive and electronics to consumer products and medical devices. Operators use KEBA controllers for pressure and temperature control, achieving optimal molding conditions for consistent, high-quality output.

Integration with auxiliary systems

Integrating toggle clamp injection molding machines with auxiliary systems is also one of its key capabilities. Achieve efficient and streamlined production processes through seamless coordination and synchronization with auxiliary equipment, reduce manual intervention and downtime, and improve the accuracy of the molding process. Plus, real-time data exchange between them. This connection enables continuous monitoring of temperature, pressure, and material flow parameters. Any deviation from optimal conditions triggers immediate adjustments, preventing defects and ensuring the production of high-quality molded products.

Ultimately

Their efficiency, precision, and intelligence have become the best helpers for injection molding in various industries. For most injection molding manufacturing industries, a toggle clamp injection molding machine can meet almost all your injection molding requirements!

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/01/22

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/01/22

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/01/22

- Topstar Special | National Science and Technology Workers Day 2024/01/22

HOT TOPIC

- .ervo motor-driven linear robots

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 2

- 21

- 23

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 5-axis CNC machine

- 62

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar