What is a horizontal injection molding machine?

2024/03/04 By Topstar

Injection molding machines are the leading production equipment of any plastic product factory today and can be divided into two types: vertical and horizontal injection molding machine. Today, we will introduce one of them, the horizontal injection molding machine. Explain to everyone their design, operation, application, and advantages.

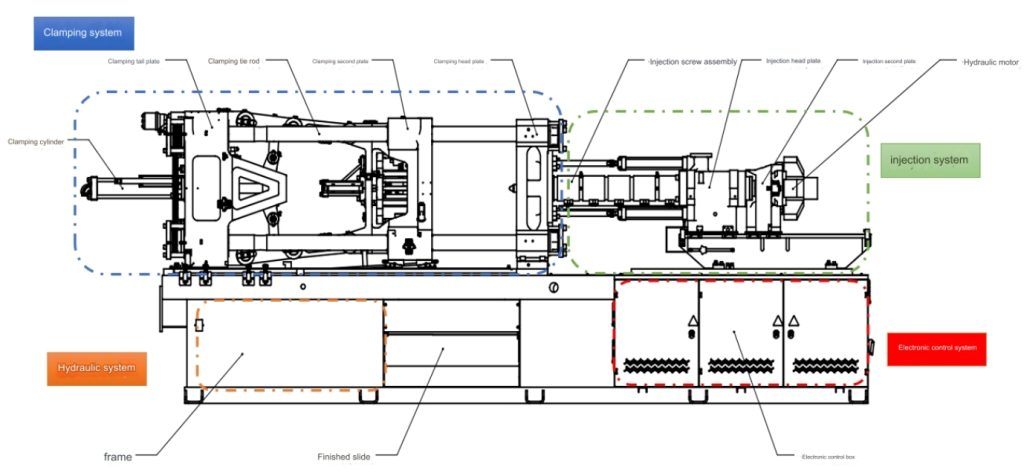

Design and construction of horizontal injection molding machines

The design and construction of a horizontal injection molding machine usually consists of several parts, including the mold clamping system, injection system, hydraulic system, and electronic control system. Then, the mold clamping device of the horizontal injection molding machine consists of a fixed platen and a movable platen installed on the horizontal guide rail. A hydraulic or electric clamping mechanism applies force to the mold halves and holds them securely closed together during injection.

The working principle of their injection system is to pull the injection platform of the injection molding machine forward through the injection cylinder, hold the injection port at the nozzle of the injection molding machine, and drive the screw to rotate (rotate) through the sol motor to move the molten plastic raw material to the injection molding machine. The material moves in the direction of the screw head, and finally, the injection cylinder pulls the second injection plate. The screw moves forward to inject the material into the mold cavity for cooling and forming.

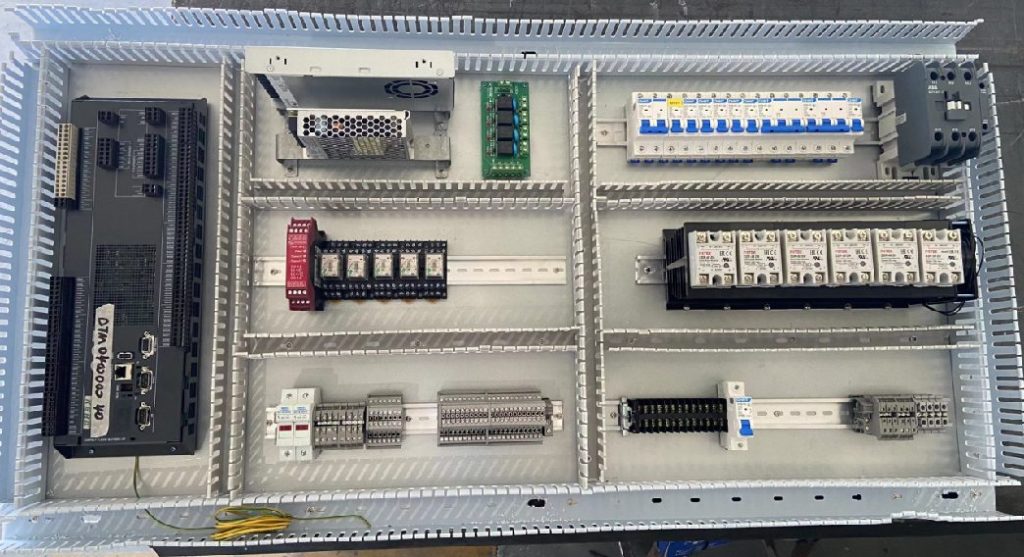

The central core of the electronic control system of the horizontal injection molding machine is the KEBA computer, which is the operation controller of the entire injection molding machine and is equivalent to the brain of the equipment. Another thing worth mentioning is their safety module, which ensures the safety of the interlocking of the various safety modules of the device. The core component of the hydraulic system is the oil brake plate. Its structure is to open many different holes in a piece of steel. The oil valve controls the opening and closing of the internal channel, interconnecting each hole and then realizing the actions of different hydraulic drive components.

Operation of horizontal injection molding machine

The production process of a horizontal injection molding machine is to load plastic resin particles into a hopper located on the top of the machine and let the particles be fed into the barrel of the injection device by gravity. After passing through the barrel of the heated injection device, the plastic resin particles are melted and move forward along a horizontal path through the injection device. The molten plastic is then injected into the mold cavity under high pressure. The mold cools, allowing the molten plastic to solidify and form into the desired shape of the part. After the parts are entirely cool and thickened, we open the mold, and the ejection mechanism pushes the finished parts out of the mold cavity. Then, the injection molding robot takes them out, repeating the process.

Advantages of horizontal injection molding machine

Compared with vertical injection molding machines, horizontal injection molding machines have a lower bed height, making it easier to change molds, maintain, and disassemble parts. Operators can easily access the mold area from the front or side of the machine, reducing downtime and increasing efficiency. They are more efficient at producing parts per cycle and have more options, such as hydraulic or electric options. In horizontal injection molding machines, their gravity helps molten plastic flow from the injection device to the mold cavity, allowing for more even filling and reducing air entrapment, improving part quality. In addition, they are compatible with various automation solutions, including injection molding robots, conveyor systems, and more.

Related applications

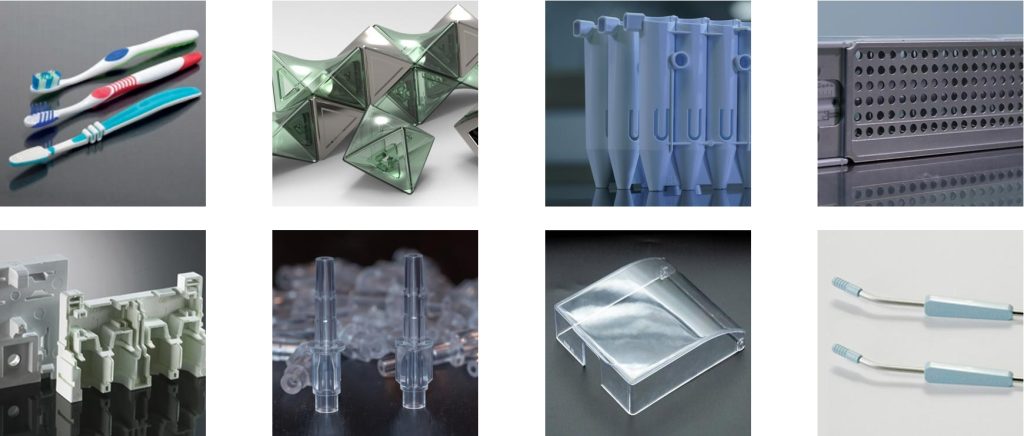

Horizontal injection molding machines often produce plastic parts in various industries. Manufactures multiple automobiles’ interior panels, door handles, and exterior body parts. It is also suitable for making electronic components such as smartphones, tablets, computers, and consumer electronics casings. In the medical industry this includes syringes, IV components, catheters, surgical instruments, and medical device housings and casings, among others. Their versatility enables easy production of complex geometries, complex designs, and high-precision parts.

Shortcoming

Of course, horizontal injection molding machines also have some disadvantages. They may be more time-consuming and labor-intensive to replace the mold, the mold cost will be higher, and they occupy a larger area and have high requirements for the production workshop. In horizontal machines, molten plastic flows horizontally from the injection unit to the mold cavity, resulting in longer flow paths and higher pressure losses, leading to potential flow-related defects. They may also have limitations in accommodating certain types of inserts or complex insert geometries.

Make good use of horizontal injection molding machines

Horizontal molding machines offer versatility, efficiency, and precision for producing plastic parts. Their application fields cover everything from electronic products to the medical industry. I need to make good use of horizontal injection molding machines based on my situation and their advantages so that I can create better products.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/03/04

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/03/04

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/03/04

- Topstar Special | National Science and Technology Workers Day 2024/03/04

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC