How to achieve better surface gloss in optical component injection molding?

2025/08/29 By le zhan

In optical component injection molding, gloss is more than just a cosmetic concern. It is directly related to surface finish, light transmittance, stray reflections, and the perceived quality of automotive, medical, and consumer optical parts. Therefore, gloss must be considered as a holistic process in production, with material, melt state, mold surface, machine precision, and process control all optimized simultaneously. Key considerations include resin selection and drying, melt uniformity, mould surface finish, and temperature control, as well as injection and holding pressure strategies, machine accuracy, and a contaminant-free production environment. Each of these variables influences micromorphology and residual stresses, ultimately determining gloss and optical performance.

Material Selection, Conditioning, and Melt Preparation in Optical Component Injection Molding

In optical component injection molding, the right raw materials are fundamental. Selecting resins with inherent optical clarity and low haze requires optimization, including PMMA for the highest gloss, polycarbonate for superior toughness, and COP/cyclic olefin polymers for excellent optical properties. Avoid resins containing flame retardants, high recycled content, or incompatible additives, as these additives can negatively impact the surface finish.

Optical polymers are typically hygroscopic. Moisture in the melt can create bubbles and microvoids, which reduce gloss and increase haze. Therefore, we require an injection molding dryer with a proven inlet dew point (typically ≤ -40°C for polycarbonate). Melt uniformity must also be ensured. Uniform melt temperature and low melt pressure pulsation minimize flow marks and shear-induced surface defects. Specialized optical screws are required in production, along with optimized compression and mixing zones to reduce unmelted particles and color streaks. Fine filtration upstream of the hot runner manifold or gate nozzle can also remove foreign matter.

Mold, Polishing, and Coating Preparation

Achieving high surface gloss in optical component injection molding requires meticulous mold design and process-friendly surface treatment. We recommend starting with high-grade tool steel. Optical-grade finishes typically require multiple polishing cycles using progressively finer abrasives to achieve single-digit nanometer Ra values and a mirror-like appearance. For ultra-fine replication, electroformed inserts or nickel plating on polished mandrels provide superior replication fidelity and extended tool life. Hard coatings, such as DLC or ceramic-like PVD, enhance wear resistance and preserve the initial polished finish in high volumes.

Regarding texture and gloss, designers should avoid microtexturing unless they explicitly require it for anti-glare purposes. Even microetching can reduce gloss and increase light scattering. If you genuinely require patterned effects, use precision laser etching technology, along with process control and prototype validation.

Maintaining mold temperature uniformity is also crucial, as gloss is very sensitive to surface temperature during filling and packing. For mold release, choose a release agent compatible with the optical polymer and, whenever possible, use air or electric release to minimize adhesive contact time.

Advantages of All Electric Injection Molding Machines in Optical Component Injection Molding

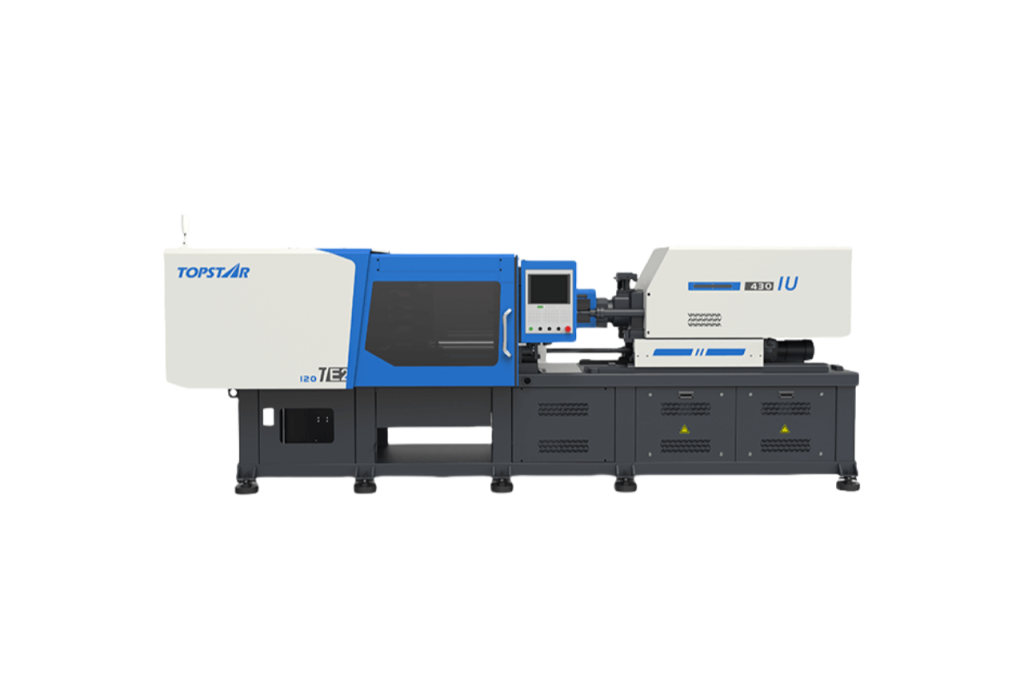

Machine performance fundamentally determines your ability to control the gloss-critical stages of the molding cycle effectively. In optical component injection molding, all electric injection molding machines provide the repeatability and fine control required to mass-produce glossy surfaces.

They enable precise metering, ensuring repeatable shot-to-shot delivery. The all electric injection molding machine utilizes an electrically driven screw. This configuration achieves tight shot weight tolerances, minimal screw return variation, and highly stable melt conditions. Furthermore, Topstar’s ally electric injection molding machines feature high holding pressure control and multi-stage holding pressure, enabling more precise and programmable holding pressure profiles, as well as rapid transitions from injection to holding pressure.

High-precision mold plate control and rapid injection-to-compression transitions enable controlled compression, slowly heating the cavity to final thickness while the melt contacts and replicates the mold surface. Compared to hydraulic systems, electric drive produces smoother velocity and acceleration profiles, reducing vibrations that can cause surface defects or micro-marks. An optical-specific screw and precision nozzle combine to achieve superior surface quality.

Optimizing the Overall Injection Molding Process

Optimizing the molding cycle is key to translating theory into production reality. For optical component injection molding, injection speed, velocity-pressure (V/P) switching, compression, and holding pressure strategies are crucial for achieving a mirror-like finish. In the injection molding of optical components, rapid filling is necessary to minimise the window for surface cooling, which typically enhances replication rates. Switching from velocity-controlled filling to pressure-controlled holding at precise points can effectively prevent weld lines and internal voids.

As previously mentioned, injection-compression technology molds the part in a slightly open cavity and then compresses it to the final thickness. This minimizes the flow length across the surface and reduces shear marks. High holding pressure is then applied to ensure the melt remains close to the cavity surface as it begins to solidify, requiring a controlled, decreasing pressure profile.

Part, Post-Molding Handling, and Quality Control

Even with optimal injection molding machine and mold settings, gloss can be compromised by downstream handling, contamination, or inadequate inspection. Gentle ejection and carefully controlled platen time during part handling can prevent scouring or drag marks. For delicate surfaces, consider using vacuum or soft-grip clamps. Keep ejection speeds as low as possible, but ensure that you avoid sticking.

In addition, optical surfaces are susceptible to particle contamination. Cleanroom or clean zone procedures should be implemented for mold polishing, molding, and post-molding processing. Use lint-free gloves, filtered air, and enclosed conveyors. Strict protective clothing and standard operating procedures (SOPs) should be implemented to control airborne particles, oil, and fingerprints. If necessary, post-molding coatings can be applied to improve scratch resistance, anti-reflective properties, or fine-tune gloss.

Ensuring Molding and Yield of Precision Optical Components

Achieving superior surface gloss in optical component injection molding requires the use of appropriate materials and drying processes, precise mold surface engineering, temperature control, all-electric injection molding machines, and rigorous process optimization and part handling. Topstar’s all electric injection molding machines deliver precise metering, high holding pressure control, injection compression, and optical screws, resulting in high surface gloss, dimensional stability, and repeatable production.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/08/29

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/08/29

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/08/29

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/08/29

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- injection moulding dryer

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar