How to Select Water Chiller Tank Capacity: Fit Injection Molding Machine Cooling Demand

2025/11/26 By le zhan

The cooling system in injection molding is a crucial element for stable performance. The water tank capacity of the water chiller is more than just a number; it determines the balance between heat dissipation and machine requirements. Insufficient capacity leads to warping and slow production cycles; excessive capacity results in wasted energy and upfront costs. In injection molding, 41% of cooling-related production problems stem from mismatched chiller tank capacity. If you’re unsure how to choose the right water chiller tank capacity to meet the cooling needs of your injection molding machine, this guide will provide the answers.

The Importance of Water Chiller Tank Capacity

Why is tank capacity the most critical factor for a water chiller—even more important than power, pump speed, or temperature range? Injection molding generates heat primarily through two methods: the molten plastic transferring energy to the mold, and the hydraulic system and motor consuming electricity.

The water chiller’s tank acts as a “thermal buffer.” It stores cooling water, ensuring a stable, constant coolant temperature for the mold and machine components. If the tank capacity is too small, the cooler cannot handle temperature peaks—the water temperature rises, the mold cannot cool the plastic quickly enough, and ultimately the parts warp or cycle times are extended. If the tank capacity is too large, the cooler needs to operate beyond its capacity to cool more water than actually required, resulting in additional energy waste each month.

4 Core Factors for Meeting Injection Molding Machine Needs

Choosing the water tank capacity for a water cooler is not simply a matter of picking a number from the catalog; it must be matched to the injection molding machine’s unique heat load. 90% of capacity-related problems can be eliminated by considering the following four factors:

Injection Molding Machine Tonnage

The tonnage of an injection molding machine is directly related to heat output. A 100-ton injection molding machine has a smaller motor, hydraulic system, and mold cavity than a 500-ton machine, and therefore requires less cooling capacity. Based on the following:

- 50–150 tons: 300–500 liter water-cooled chilled water tank

- 150–300 tons: 500–800 liter water-cooled chilled water tank

- 300–500 tons: 800–1200 liter water-cooled chilled water tank

- Over 500 tons: 1200–2000 liter water-cooled chilled water tank (or multiple chillers in parallel)

Plastic Material

Different plastics have different insulation properties, which affect the cooling capacity required by the water chiller. Thermoplastics, such as ABS and PC, have higher insulation properties. Compared to low-heat materials such as PP or PE, they require 20-30% larger tank capacity.

For example, a 300-ton injection molding machine used to produce PC car bodies requires a 1,000-liter water-cooled tank. Why? PC has a melting point of 500°F and a slow heat dissipation rate—smaller tanks cannot buffer this continuous energy transfer.

Part Thickness and Number of Cavities

Thick-walled parts have greater plastic mass, which results in more heat being released into the mold. A four-cavity mold (producing four parts at a time) generates twice the heat of a two-cavity mold. For every 5 mm increase in part thickness or doubling of the number of cavities, the tank capacity needs to be increased by 10% to 15%.

Ambient Temperature

In hot, humid workshop environments, water chillers experience higher workloads. If your workshop ambient temperature exceeds 85°F, you need to increase the tank capacity by 15% to 20%. Why? High temperatures reduce the cooling efficiency of water chillers—a larger tank can maintain a lower water temperature between cycles.

Water Chiller Tank Capacity: Step-by-Step Calculation

You don’t need complicated calculations to determine the capacity of your water chiller tank—you can get an accurate value using the following simplified formula:

Recommended Tank Capacity (L) = Baseline Capacity (calculated based on tonnage) × Material Factor × Thickness/Cavity Factor × Environmental Factor

Let’s understand this through a practical example: a 300-ton injection molding machine in a factory, using a 4-cavity mold to produce 10mm thick PC parts:

Step 1: Obtain the Baseline Capacity

300-ton machine = Baseline capacity 800–1,200 liters. We will use 1,000 liters (an intermediate value suitable for 24/7 operation).

Step 2: Apply the Material Factor

PC material = High insulation → Factor = 1.3 (30% increase). 1,000 liters × 1.3 = 1,300 liters.

Step 3: Apply Thickness/Cavity Factor

10mm thickness + 4-cavity mold → Factor = 1.2 (plus 20%). 1,300 liters × 1.2 = 1,560 liters.

Step 4: Apply Environmental Factor

90°F (32°C) workshop → Factor = 1.2 (plus 20%). 1,560 liters × 1.2 = 1,872 liters.

Final Recommendation: 1,900-liter water-cooled chiller tank.

Avoid 5 Costly Capacity Mistakes

Even with the calculation formula, small mistakes can lead to huge losses. Here are a few common pitfalls.

- The Bigger the Better

A manufacturer, to be on the safe side, bought a 2,000-liter water-cooled chiller for a 200-ton injection molding machine. The result? Energy bills increased by 18% (due to the chiller unnecessarily cooling excess water), resulting in thousands of dollars of upfront waste. Overcapacity adds 10-20% to energy costs annually.

- Neglecting Mold Cooling Circuit Design

Narrow cooling channels and inefficient molds restrict water flow, increasing the chiller’s operating load even with the correct tank capacity. If your molds are not cooling effectively, increase the tank capacity by 10% or upgrade the mold’s cooling circuit.

- Selecting Tank Capacity Based on a Single Injection Molding Machine, Not the Entire Production Line

If a chiller cools multiple injection molding machines, the tank capacity should be determined by the total heat load, not the capacity of the largest machine. A production line containing 150-ton and 250-ton machines requires a 1200-liter tank (500 liters + 700 liters), not just the baseline capacity of the 250-ton machine.

Choosing the Right Chiller Tank Capacity

Choosing the right water chiller tank capacity depends on the heat load of the injection molding machine. A tank that efficiently buffers and dissipates heat should be selected. Insufficient capacity will lead to waste accumulation, extended production cycles, and operator frustration; excessive capacity will result in wasted upfront costs and energy. If you are unsure of your production capacity needs, Topstar will analyze your situation and recommend a water chiller that meets both current and future requirements.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/11/26

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/11/26

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/11/26

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/11/26

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

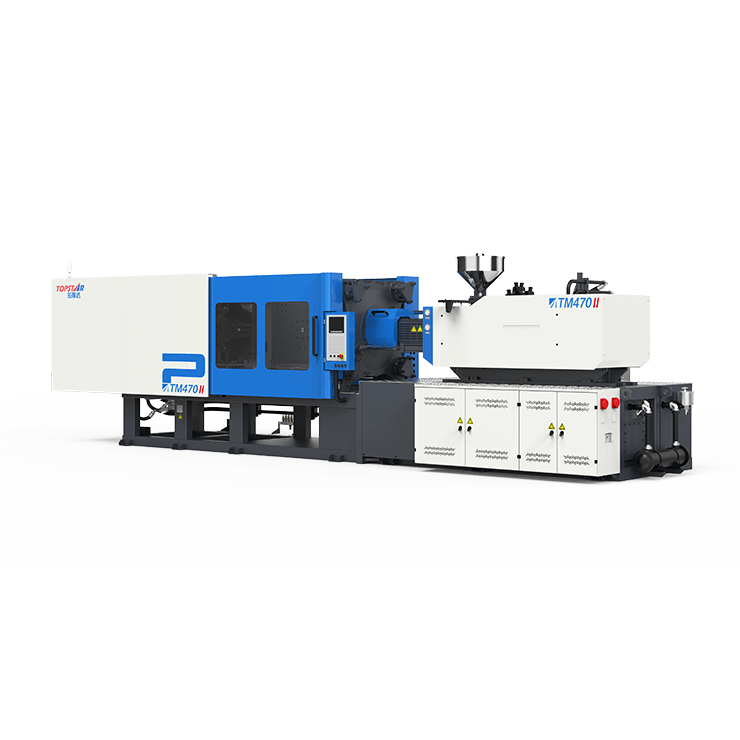

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar