Choosing Screw and Barrel Profiles for Packaging Injection Molding

2025/09/22 By le zhan

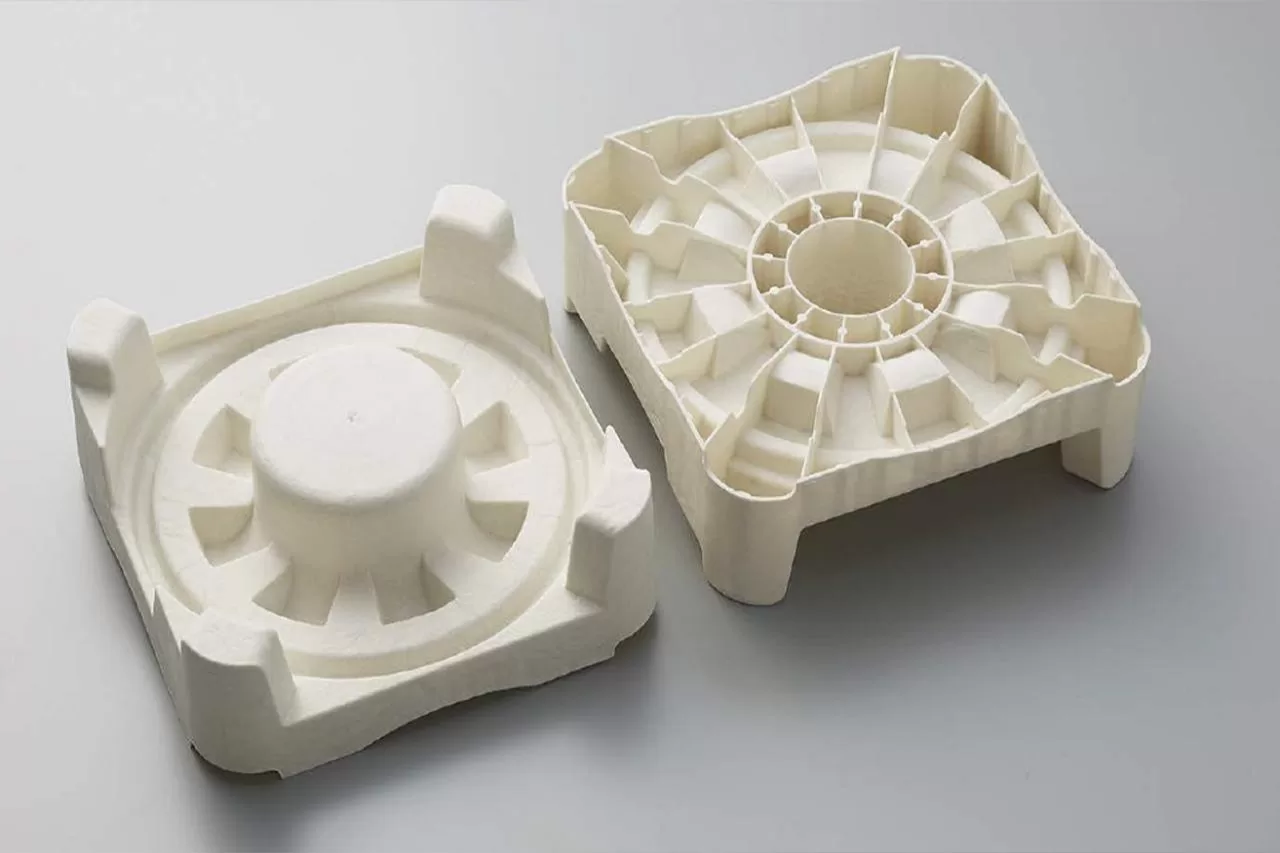

Selecting the correct injection molding screw and barrel profile is the most critical decision in packaging injection molding. Packaging components such as thin-walled barrels, caps, closures, trays, and high-speed containers require a delicate balance of rapid plasticization, uniform melt quality, minimal residence time, low shear degradation, and consistent shot-to-shot repeatability on the injection molding machine. Improper screw/barrel selection can lead to poor melt uniformity, lost cycle time, increased scrap, shortened screw life, and costly downtime. Therefore, selecting the right screw/barrel ensures predictable throughput, a tighter process window, and lower overall cost per part.

Choosing the correct screw geometry for packaging injection molding

Screw geometry controls the plasticization rate, melt quality, and shear history. The most common screw types for packaging injection molding are general-purpose (single-flight), barrier (two-stage), and/or shear-type compounding screws. These screws need to be selected to match the polymer characteristics and production goals.

First, select the length-to-diameter ratio (L/D). The packaging industry tends to favor medium aspect ratios, typically between 18:1 and 24:1, because packaging resins require not only efficient melting and good mixing but also rapid production. A higher aspect ratio increases residence time and mixing length, improving homogeneity. For thin-wall, high-speed packaging, rapid plasticization is crucial, so an aspect ratio of 20:1 is a common compromise. Secondly, the compression ratio (CR) is determined. Common CR packaging values range from 2:1 to 3:1. A higher CR promotes faster melting and a denser melt by compressing the material and enhancing conductive heat transfer in the transition zone. For PP, a CR of 2.2-2.8 generally offers a good balance, though higher CRs may be beneficial for certain high-viscosity engineering resins used in barrier packaging.

Furthermore, degassing and venting must be considered. While most packaging resins are dry and do not require degassing, processes involving regrind or high volatile content require barrel venting or vacuum degassing to prevent bubbles and pinholes in thin-walled parts. Finally, screw diameter and pitch affect shot size and plasticizing rate. Packaging typically requires a higher injection-screw ratio to maintain short residence time. Matching screw diameter to shot size so that the screw can recover 1-2 times the shot size per minute within the target cycle time can avoid long idle dwells and improve thermal stability.

Polymers for Common Packaging Resins

Each polymer used in packaging injection molding has its own unique melting behavior, which influences screw and barrel selection. The following are some of the most common resins: PP, HDPE, PET, and PS.

PP: PP is a workhorse in the packaging industry. It is shear-resistant, but a moderate compression ratio of 2.2-2.8 and a barrier screw accelerate the melt without excessive shear. Use a relatively coarse metering screw depth to maintain output and minimize residence time.

HDPE: HDPE has a higher viscosity and is more sensitive to residence time. A slightly longer length-to-diameter ratio of 20:1–24:1 and a smaller compression ratio of 2.0–2.5 are recommended to avoid shear heating. Unless significant regrind is present, in-barrel venting is generally not necessary. Additionally, to ensure uniform color, select mixing elements that disperse without high shear.

PET: PET used to produce preforms is typically preform injection molded and then stretch-blow molded. Injection molding screws are optimized to control crystallinity and minimize melt residence time. PET requires excellent moisture control, and screw geometry generally favors a low compression ratio, precise metering, and a smooth surface finish to minimize deposit formation and reduce risk.

PS and HIPS: PS has low viscosity and melts easily. General-purpose screws with a low compression ratio of 1.8-2.2 work well. If using high-impact polystyrene (HIPS) or filled grades, consider using a gentle mixing section.

Barrel Materials, Wear Resistance, and Maintenance for Packaging Injection Molding

Packaging operations operate in large batches and often use regrind and fillers, which can accelerate wear. Therefore, specifying the correct barrel and screw materials, surface treatment, and regular maintenance is essential. In injection molding, standard barrels are carbon steel with a chrome-plated interior. For packaging containing abrasive additives or high backgrinding content, bimetallic barrels or more wear-resistant options, such as tungsten carbide-coated bores or nickel-based weld overlays, are available. These options can significantly extend service life in abrasive applications, but they increase upfront costs.

Select screw heads and flights with hardened steel and surface treatments. Case hardening and a thin, hard coating improve wear resistance and reduce sticking. For polymers prone to deposit formation (e.g., PVC, PET), you can select a polished surface treatment to prevent deposits and help maintain consistent shear forces. Regularly check the cycle during production runs to monitor metering groove depth, transition geometry, and screw tip roundness. Measure plasticization rate over time and track torque increases. Also, maintain spare screw and barrel sets for replacement during planned maintenance without requiring extended downtime. Using pre-qualified spare sets for changeovers is an industry best practice in high-volume packaging injection molding lines.

Machine Matching, Injection-Plasticization Ratio, and Production Targets

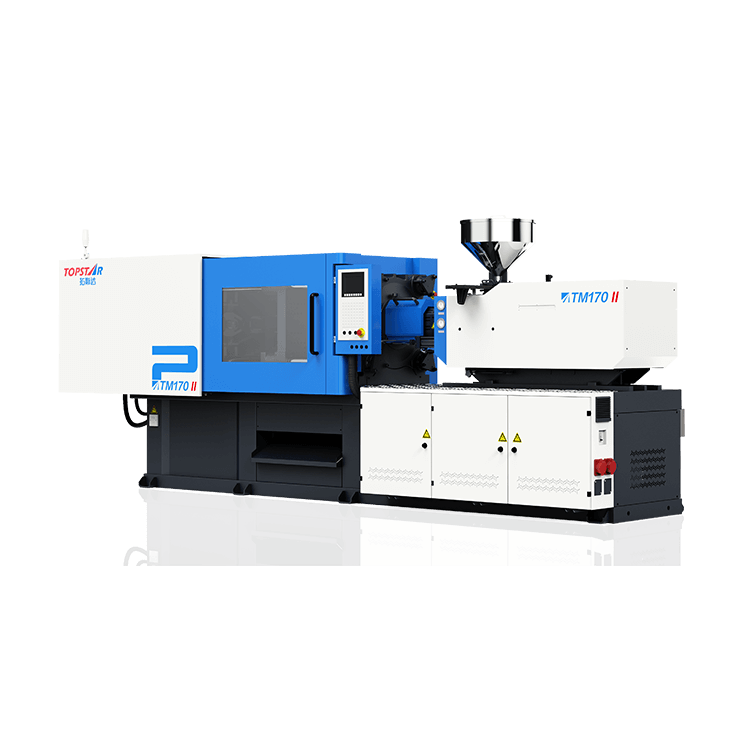

The screw and barrel selection must be matched to the selected injection molding machine. The matching of the injection molding machine determines packaging decisions: the ratio of shot size to plasticization volume, and the screw recovery rate relative to cycle time.

Regarding the injection-plasticization ratio, the screw must be able to plasticize enough material in a single cycle to meet your shot size, with ample margin. Therefore, select the appropriate screw size to achieve the desired shot size, which represents 35% to 70% of the screw’s available metering capacity within the target cycle. If the screw capacity is insufficient, the cycle must include additional plasticization time, which increases the cycle time and reduces output. Conversely, severely insufficient screw capacity increases melt residence time and thermal stress.

For high-speed packaging lines, select a screw with higher plasticization capacity and a higher motor torque. The goal is to complete plasticization of the next shot while the part cools—achieving target output and avoiding extended residence time due to idling. For example, if your cycle time is 6 seconds and your shot size is 15 grams, the screw must plasticize at a rate of at least 150 grams per minute to maintain a tight melt time margin. Furthermore, the barrel/screw must be paired with an injection molding machine capable of providing sufficient injection pressure and speed to fill thin-walled gates. Thin-walled containers, on the other hand, require extremely high injection speeds and precise pressure control, so you must ensure your injection molding machine equips a servo-hydraulic or fully electric drive system.

Selecting a Screw and Barrel Based on Production Goals

Choosing a screw and barrel profile for packaging injection molding is a systematic decision. Polymer selection, part geometry, cycle time goals, and injection molding machine performance must be considered comprehensively to select the appropriate aspect ratio, compression profile, mixing elements, and barrel metallurgy to deliver consistent melt quality while meeting your desired output. A suitable combination of, for example, a barrier screw for fast thin-wall injection molding, an L/D ratio for viscous or recycled blends, and a hardened barrel for filled resins can directly reduce scrap rates, minimize downtime, and improve unit economic benefits.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/09/22

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/09/22

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/09/22

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/09/22

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar