Learn how to quickly solve molding machine nozzle clogging problems in 5 minutes

2025/11/05 By le zhan

Unplanned downtime in injection molding often stems from nozzle clogging, resulting in an average loss of hundreds of dollars per hour in production. A Michigan-based auto parts manufacturer reported losing over a dozen hours per month due to nozzle clogging, resulting in significant waste of production time. Nozzle clogging, caused by solidified molten plastic or debris blocking flow, leads to production stoppages, mold damage, and material waste. 90% of molding machine clogging issues can be resolved within 30 minutes with the right steps.

Causes of Molding Machine Nozzle Clogging

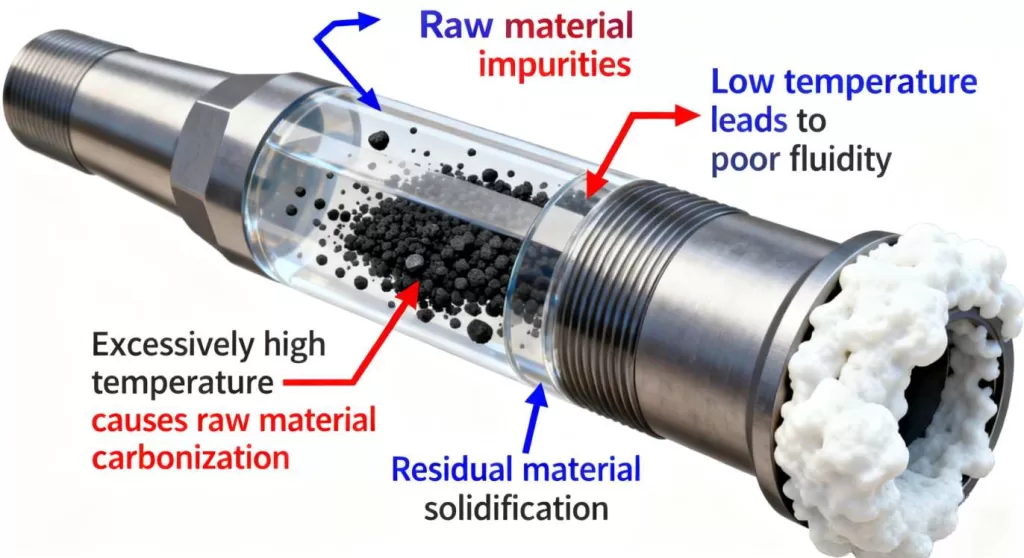

Before troubleshooting nozzle clogging, it is essential to understand its causes. Molding machines nozzle clogging is typically caused by four common problems, each with clear signs:

Material Residue Accumulation: Over time, carbonized (burnt) residue can remain in the nozzle, forming a hard, black blockage. This results in reduced flow and burnt marks on parts.

Cold Blockage: If the nozzle temperature is below the plastic’s melting point, the molten plastic can solidify at the nozzle tip, forming a “blockage” that obstructs flow. This can cause sudden pressure spikes during injection molding and incomplete part filling.

Foreign Objects: Contaminants enter the nozzle, blocking fluid flow. Symptoms: Abnormal noise during injection and uneven part quality. Incompatible Materials: Mixing resins or using additives that react at high temperatures can produce viscous deposits that clog the nozzle. This can result in plastic stringing and inconsistent injection volumes.

Steps for Quickly Clearing Molding Machine Nozzles Clogs

When clogging occurs, speed is crucial. Follow these steps to quickly and safely clear the blockage: First, stop and lock the machine, then turn off the molding machine’s power and release the hydraulic pressure. Wait 5-10 minutes to allow the nozzle to cool slightly. Then, determine the type of blockage. For soft blockages, heat the nozzle to 10-15°C above the material’s melting point. For stubborn blockages, keep the nozzle at operating temperature to avoid breakage during the clearing process. Simultaneously, clean the nozzle by loading a cleaning agent into the hopper. Perform 2-3 short-distance injections at 80% pressure; the abrasive will remove soft residue. Alternatively, manual clearing can be used; gently push the blockage away with a nozzle cleaning tool. Be careful not to use sharp tools, as they can scratch the nozzle and cause re-clogging. Finally, test with pure resin. Perform 1-2 injections with the virgin resin to ensure smooth flow. Before resuming production, check that the pressure is stable and that the parts are of good quality.

Preventive measures to avoid clogging

The best way to prevent clogging is to avoid it altogether. The following proactive measures can reduce the risk of clogging by 70%. First, optimize temperature settings by using a heat probe to verify that the nozzle temperature is within the recommended range for the resin. For sensitive materials, increase the buffer temperature by 5°C to prevent cold spots. Then, pre-treat the material. For hygroscopic resins, dry them before use using a desiccant dryer, setting the settings according to the resin’s drying specifications. For example, PC resin requires drying at 120°C for 4 hours.

In injection molding, cleaning is necessary when changing materials. When changing resins, use a neutral detergent to clean the injection molding machine nozzles to remove residual material. This is especially important when switching from PVC to other plastics. During daily production, inspect the nozzles for wear, cracks, or buildup, and replace any worn nozzles to ensure a smooth water flow.

When quick fixes are insufficient to resolve the problem

If clogging persists after taking preventative measures, a thorough investigation is required. These problems often lurk behind persistent blockages:

Heating belt malfunction: A malfunctioning heating belt can create cold spots within the nozzle, leading to recurring cold sprays. Use an infrared thermometer to check for temperature consistency.

Nose alignment issues: Misalignment between the nozzle and the mold gate bushing can cause material backflow and blockages. Use a feeler gauge to check alignment; adjustments are needed if the gap is greater than 0.05 mm.

Excessive back pressure: Setting the injection molding machine‘s back pressure too high can cause plastic shearing and overheating, leading to carbonization. The back pressure should be reduced to the minimum required to ensure material uniformity.

Material contamination: If foreign matter persists, check the hopper, feed inlet, and material storage device. Install a magnetic separator in the feed line to capture metal debris.

Tools to simplify blockage troubleshooting

Having the right tools can reduce troubleshooting time for blockages by 40%. Here are some tools that should be readily available for every injection molding operation:

Nose cleaner: Select a grade that matches your resin type. For example, use a high-temperature resistant formula for PEEK and a grinding formula for carbonized residues.

Nozzle Cleaning Tools: A set of heat-resistant rods with blunted tips to prevent sharp edges from damaging the injection molding machine nozzles.

Thermal Probe/Infrared Thermometer: Used to verify nozzle temperature and identify cold spots.

Feeler Gauge: Used to check the alignment of the nozzle mold.

Magnetic Separator: Installed on the feed line to intercept metal contaminants before they reach the nozzles.

Troubleshooting Nozzle Clogging and Improving Production Efficiency

Nozzle clogging is unavoidable in injection molding, but it doesn’t necessarily kill production. By understanding the root cause, taking quick cleanup steps, and implementing preventative measures, you can resolve 90% of injection molding machine clogging issues within 30 minutes and reduce recurrence rates by 70%. The key is to act quickly, use the right tools, and conduct regular inspections and maintenance.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/11/05

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/11/05

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/11/05

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/11/05

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar