The trade-off between payload and speed of the injection molding robot

2025/06/20 By Topstar

The key to selecting the right injection molding robot for your injection molding machine is to strike a balance between payload and speed. Payload refers to the maximum weight that the injection molding robot can carry, while speed refers to the speed at which the arm moves along its axis. Both factors directly affect cycle time and output, and therefore, balancing payload and speed is critical, especially when integrating these high-speed injection molding robots into complex production lines. As payload capacity increases, robot speed typically decreases due to increased inertial loads and the need for more powerful drives. Conversely, ultra-high-speed robots normally have lower payload ratings to maintain precision and position accuracy under high acceleration.

Impact of the Mechanical Design of Injection Molding Robot on Payload and Speed

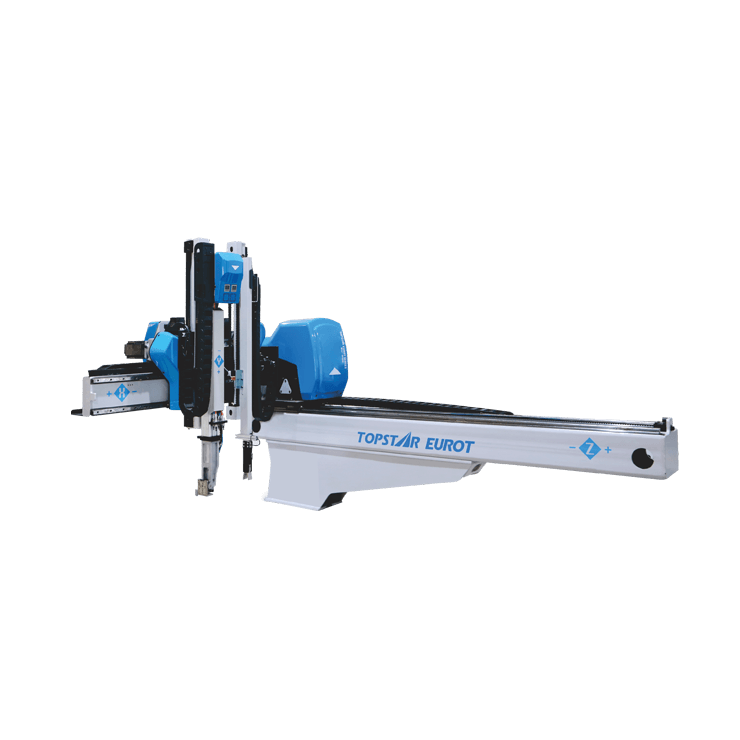

The mechanical structure of an injection molding robot fundamentally determines its payload and speed capabilities. Inform manufacturers to adopt linear robots or three-axis robots for part extraction in plastic molding. Linear robots excel at horizontal movement, providing high-speed performance with payloads typically up to 10 kg, making them ideal for small and medium-sized injection molding machines. However, their vertical payload capacity decreases at maximum reach, so speed is naturally limited when carrying heavier parts over long distances.

On the other hand, 3-axis robots offer linear motion on three axes, supporting heavier payloads (sometimes up to 50 kg) but at the expense of acceleration and top speed. However, linear robots sacrifice payload when fully extended, while three-axis robots trade speed for payload and stability. Engineers often use lightweight aluminum components to reduce the robot arm’s inertia, enabling higher speeds without payload compromise.

Control systems and dynamic performance of the injection molding robot

In addition to mechanical design, control systems, and motion algorithms can also balance payload and speed. Topstar’s injection molding robots are controlled by servo drives that continuously adjust motor torque and position in response to load changes. For example, adaptive acceleration profiles automatically adjust speed during start-stop cycles to prevent overshoot and ensure gentle handling of heavy parts. For example, when lifting a 15 kg automotive part, the control system reduces peak acceleration by 20% to maintain position accuracy and avoid mechanical stress.

Additionally, we can optimize trajectory planning for the jerk, enabling the injection molding robot to exceed speed limits while maintaining smooth motion. Minimizing mechanical vibration and cyclic fatigue, these control strategies extend service life and maintain precision while also fine-tuning the injection molding robot to deliver the payload capacity and speed required for various molding applications.

Application-Driven Payload and Speed Considerations

Different manufacturing scenarios require injection molding robots to make different trade-offs between payload and speed. In high-volume consumer product production, such as plastic bottle caps or miniature electronic product housings, high-speed injection molding robots with payloads of 2 to 5 kg are typically capable of maximizing throughput and achieving cycle times under 5 seconds. In contrast, in automotive or aerospace applications, parts can weigh more than 20 kg and require secondary assembly, so the robot must prioritize payload over top speed, even if that means extending the cycle time to 10 to 15 seconds.

Additionally, multi-step processes, such as insert molding, add further complexity. The injection molding robot must handle heavy metal inserts or reposition parts between mold cavities. Hence, it needs a strong payload capacity and sufficient speed to keep up with the injection molding machine cycle. Therefore, interlocking between the machine clamping unit and the robot axis synchronization ensures safe, collision-free operation, reducing downtime and preventing damage to sensitive parts.

Innovations in Payload Speed Optimization

Recent advances include the use of harmonic drive gearboxes, which enable robots to lift heavier parts without sacrificing acceleration. Similarly, torque vectoring technology borrowed from automotive engineering can distribute motor torque to multiple axes, allowing higher payloads to be handled at faster speeds in diagonal or compound movements.

Additionally, the design of injection molding robots is now modular, enabling customers to add or remove extension links to adjust arm length and payload capacity for specific tasks. In addition, injection molding robots equipped with torque sensors can provide safe and adaptable payload handling in shared human-machine workspaces.

Effectively balance load and speed.

Balancing load and speed is a complex interaction of multiple factors, including mechanical design and control systems. We can make trade-offs by understanding how the robot architecture affects inertia, how the servo drive control optimizes motion, and how the actual use case determines performance priority. Ultimately, we must combine the specifications of the injection molding robot with your production goals to ensure that each cycle achieves maximum throughput without compromising reliability or safety.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/06/20

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/06/20

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/06/20

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/06/20

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar