How to choose a mold temperature controller suitable for thick-walled automotive products?

- Large flow water type mold temperature controller

- mold temperature controller

- water type mold temperature controller

2025/07/19 By Topstar

When selecting the right mold temperature controller for thick-walled automotive parts, it’s essential to understand the performance requirements. In our experience, using a 120°C high-flow water-based mold temperature controller can reduce cycle times by 12% to 15% for parts with walls thicker than 20 mm. The controller features a high-pressure pump capable of delivering up to 25 L/min at 8 bar pressure, along with a 20 mm diameter cooling solenoid valve, which accelerates heat dissipation. This ensures even heat distribution throughout the mold by increasing flow and head pressure, thereby minimising thermal gradients.

Pump Capacity and Hydraulic Considerations for Mold Temperature Controller

The pump for a mold temperature controller must be able to handle the large volumes and significant back pressures required to circulate coolant through complex, thick-walled molds effectively. For example, a centrifugal pump rated for 25 L/min can ensure adequate coolant turnover even in large manifold systems, and its high-head design overcomes the resistance of narrow cooling channels and long pipe runs without causing cavitation. During testing, we verify pump performance using in-line flow meters and differential pressure gauges to confirm actual delivery under static and dynamic mold conditions. Additionally, an insulated pump housing reduces heat loss by 5%, thereby enhancing energy efficiency. By prioritising flow and head pressure, using a high-flow water mould temperature controller can maintain a rapid thermal response and a consistent mould temperature, thereby avoiding hot spots and warping in thick sections while optimising energy usage.

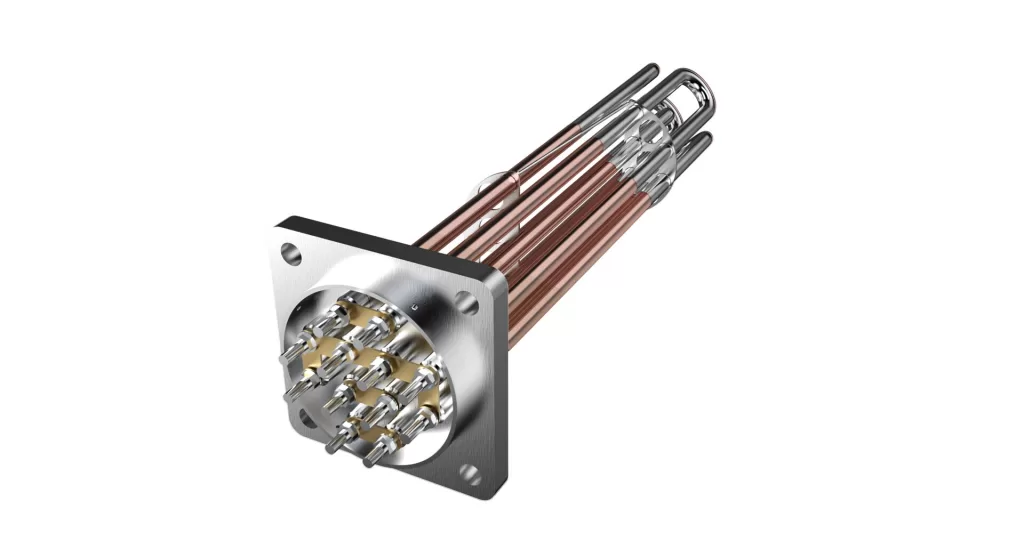

Heating Elements and Temperature Uniformity

To achieve precise control up to 120°C, we use heating elements and PID control algorithms in the mold temperature controller to ensure uniformity in all areas. During manufacturing, we install distributed cartridge heaters, each rated at 1 kW, placed every 300 mm along the dual heating loop to maintain uniform heat flux. At the same time, I developed an adaptive PID loop with an auto-tuning function to keep the set point within ±0.5°C, even under rapid load changes exceeding 20°C per minute. And we utilized a large surface area shell and tube heat exchanger to increase the speed of the heating and cooling phases by 30%. Additionally, the preset holding time stabilizes the temperature before injection, ensuring the material does not overheat. These design choices enable the mold temperature controller to rise from ambient temperature to 120°C in 10 minutes, reducing downtime in high-cycle automotive molding operations.

20 mm solenoid valve in the mold temperature controller

For thick-walled automotive parts that require a fast and reliable cooling phase, we installed a 20 mm diameter proportional solenoid valve in the 120°C high-flow water mould temperature controller. This modification increased the maximum coolant throughput by 25%, thereby achieving a faster cooling speed. At the same time, I integrated a high-speed valve driver that can adjust the opening according to real-time temperature feedback, achieving a cooling rate of up to 5°C per minute while maintaining an accuracy of ±1°C. Additionally, the dual-circuit cooling design allows for targeted heat dissipation, preventing thermal shock and uneven shrinkage. And we’ve programmed “burst” cooling sequences that instantly increase flow at critical mold stages, further reducing cycle times without compromising temperature control. This approach ensures your high-flow water-based mold temperature controllers meet the stringent requirements of thick-wall automotive part production.

Intelligent Control Features and User Interface

Advanced control features and connectivity are available in the mold temperature controllers, enabling optimised process management and enhanced traceability. In addition to a touchscreen that supports multi-touch gestures, the mold temperature controllers offer OPC UA and Modbus TCP interfaces, enabling seamless SCADA integration. Alarm thresholds for overheating, flow loss, and heater failure are configured to ensure immediate notification to the operator. In addition, embedded data logging records temperature, pump speed, and valve position at one-second intervals, generating trend graphs for SPC analysis. Automatic batch report generation simplifies compliance with automotive quality standards such as IATF 16949. By leveraging these advanced control features and user-centric interfaces, your production team can gain actionable insights into the performance of your mold temperature controllers, enhancing preventive maintenance and reducing scrap rates.

Installation, Maintenance, and Lifecycle Costs

Implementing mold temperature controllers in automotive thick-wall parts also requires attention to proper installation, maintenance procedures, and total lifecycle costs. First, place the mold temperature controller within two meters of the mold block to minimize line losses and improve response time. Then, use flexible PFA-lined hoses rated for 150°C and 10 bar to accommodate tool movement without kinking. Meanwhile, it is recommended that you check the integrity of the pump impeller and valve seals quarterly, and it is recommended to replace the solenoid valve diaphragm annually to prevent leaks. Our high-flow, high-lift system reduces the total TCO by 18% compared to traditional 90°C units. Reliable installation practices, coupled with proactive maintenance and detailed cost analysis, can extend the life of the mold temperature controller and ensure the continued performance of thick-wall molds.

Ensure the reliable quality of thick-walled automotive parts.

The key to selecting a mold temperature controller for thick-walled automotive products is to choose one equipped with a high-lift pump, strategically distributed heating zones, and a 20mm proportional cooling solenoid valve. In the 120°C high-flow water mould temperature controller, I configured a large-capacity pump, installed a rugged cartridge heater, integrated a fast-response valve, and utilised an advanced HMI, ensuring tight thermal regulation, shorter cycle times, and excellent part quality.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/07/19

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/07/19

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/07/19

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/07/19

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar