How can I prevent material degradation by adjusting the molding machine barrel temperature?

2025/10/24 By le zhan

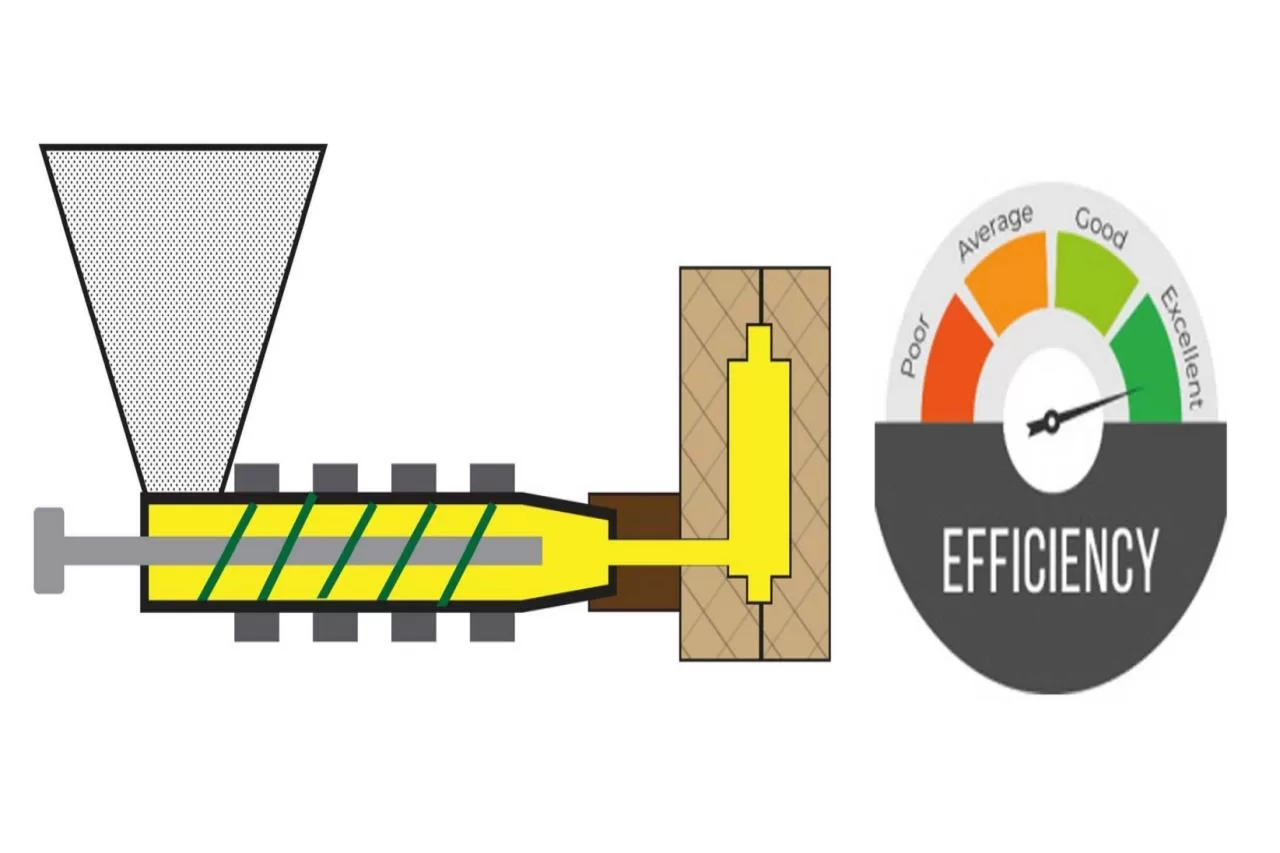

Every year, many manufacturers waste 5-10% of their raw materials due to degradation, equivalent to significant resource losses for a medium-sized enterprise operating 24/7. Worse still, these manufacturers fail to realize that degradation is the root cause of part defects. As an injection molding machine manufacturer, I’ve found that 70% of degradation cases are due to a single, controllable factor: incorrect molding machine barrel temperature. Thermoplastics such as PP, PC, and ABS have a narrow “safe zone” within which they melt uniformly without decomposition. Even temperatures exceeding this range by 10°C can cause degradation, requiring precise temperature control to eliminate this risk.

What is Material Degradation? The Importance of Molding Machine Barrel Temperature

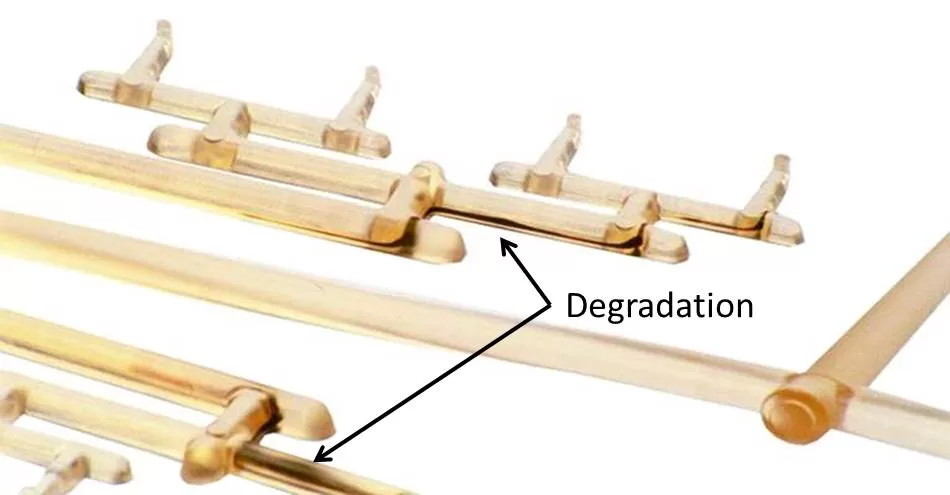

Material degradation refers to the molecular breakdown of thermoplastics during the injection molding process. This can result in discoloration, yellowing (common in PP or ABS), or black specks. It can also cause brittleness, resulting in easily broken parts, poor melt flow, and uneven viscosity, which can lead to short shots or flash. These issues are often caused by barrel temperatures that are too high or too low. Thermoplastics have a strict “processing window,” a temperature range within which they can fully melt without degrading. For example: PP: 170°C–220°C; PC: 260°C–320°C; ABS: 220°C–280°C.

Above these temperature ranges, heat breaks down the plastic’s molecular bonds. Below these temperatures, the plastic doesn’t fully melt and therefore remains in the barrel longer, subjecting it to heat for longer than expected. Topstar injection molding machines allow you to target this temperature range precisely, but you first need to determine the specific temperature range for your material.

Step 1: Determine Your Material’s Processing Temperature

The first rule for preventing material degradation is to know your material’s processing temperature before you start molding. Guessing at the right temperature leads to waste. Here’s how to do this, and how Topstar molding machines simplify the process:

Check the material datasheet: Every resin supplier provides a “processing temperature range” for their product. Highlight the middle 50% of this range (e.g., for PP’s 170°C–220°C window, focus on 190°C–200°C) to avoid extremes.

Using Topstar Molding Machines: Topstar injection molding machines come with a built-in database of over 500 common thermoplastics (PP, PC, ABS, etc.) pre-loaded with processing temperatures. Select your material, and the molding machine automatically sets the starting barrel temperature, eliminating manual guesswork.

Small-batch test: Run 10-20 parts at a preset temperature. Inspect for signs of degradation. If the parts appear clean, maintain the range. If not, adjust in 5°C increments.

One packaging customer using a Topstar injection molding machine to produce PP lids initially skipped this step and set the temperature to 225°C. They discovered a 12% scrap rate due to the yellowing of the lids. After loading Topstar’s PP at the preset temperature (195°C) and testing, the scrap rate dropped to 1.5%.

Step 2: Zone-by-Zone Barrel Temperature Adjustment

The barrel of molding machines doesn’t have a single temperature zone. Instead, it’s divided into three to five zones (feed zone, compression zone, metering zone, and sometimes a nozzle zone), each requiring a different temperature to prevent degradation. Topstar’s injection molding machines allow you to adjust each zone independently, a key feature that’s lacking in cheaper machines. The settings for each zone are as follows:

- Feed Zone: Cooling to prevent “bridging”

Goal: Keep the resin solid before entering the compression zone. Excessive heat here can cause premature melting, adhesion to the barrel, and degradation.

Setting: 10°C to 20°C below the metering zone temperature. - Compression Zone: Gradual Heating

Goal: Evenly melt the resin and avoid overheating and sudden temperature jumps.

Setting: 5°C to 10°C below the metering zone temperature. - Metering Zone (near the nozzle): Peak Temperature

Goal: Completely melt the resin and achieve smooth flow. This is the only area where the material’s processing limits are reached.

Setting: The middle value of the material’s processing window. - Nozzle Zone: Sync with Metering Temperature

Goal: Prevent “drooling” and maintain a stable melt temperature. Too high a temperature will cause the resin to degrade in the nozzle; too low a temperature will cause the resin to solidify.

Setting: Same as the metering temperature (195°C) or 5°C lower (190°C).

Step 3: Monitor Material Dwell Time in the Barrel

Even with ideal zone temperatures, excessive dwell time in the barrel can lead to material degradation. This is common during production pauses or when the shot size is small relative to the barrel capacity. Here’s how to manage this with a Topstar injection molding machine:

Calculate Maximum Dwell Time: Check the “Maximum Allowable Dwell Time” on the material datasheet; for example, 8 minutes for ABS and 10 minutes for PP.

Set a Topstar Dwell Time Alarm: The injection molding machine tracks the dwell time, or the time the material remains in the barrel. If a set limit (e.g., 8 minutes) is exceeded, an audible/visual alarm sounds, and a small amount of resin is automatically purged to refresh the barrel.

Purge on Demand: If the dwell time exceeds the limit, purge 1-2 shots of resin to remove degraded material. Never leave old resin in the barrel.

Step 4: Calibrate the Molding Machine’s Temperature Sensor

Even the best regional settings can be ineffective if the molding machine’s temperature sensor is inaccurate. Over time, the sensor drifts due to heat and vibration, so the machine may report a temperature of 195°C when the barrel is actually 205°C. The Topstar injection molding machine addresses this issue with a built-in calibration tool:

Access the calibration menu: Navigate to “Tools > Temperature Calibration” on the machine’s touchscreen.

Use a certified thermocouple: Connect a handheld, NIST-certified thermocouple to the barrel to measure the actual temperature.

Adjust the sensor offset: If the machine reading is 5°C higher than the thermocouple, set a -5°C offset in the menu. Topstar saves this calibration value for future runs. We recommend calibrating your sensors every three months. A quick calibration, which takes just 15 minutes, can prevent costly performance degradation.

Injection Molding Machine Temperature Regulation: The Top Solution for Material Degradation

Material degradation isn’t a costly factor in the injection molding process. By determining material temperature, precisely adjusting barrel zones, monitoring dwell time, and calibrating sensors, you can reduce scrap and save thousands of dollars annually. All Topstar injection molding machines are designed to simplify these steps—with material presets, independent zone control, dwell time alarms, and built-in calibration tools—you can spend less time troubleshooting and more time producing high-quality parts.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/10/24

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/10/24

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/10/24

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/10/24

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar