How to detect and repair hydraulic line leaks in plastic injection molding machine?

2025/09/12 By le zhan

Hydraulic line leaks are one of the most common and devastating field failures in plastic injection molding machine. A small leak can quickly escalate into a slippery and dangerous situation. A persistent leak can reduce press performance, contaminate parts, and force the late shift production line to shut down. Leaks typically manifest as visible oil stains, pressure loss, unexpected drops in the oil tank level, intermittent cylinder pressure failures, or water accumulation at the bottom of the machine. However, not all leaks are obvious; many begin as small leaks and gradually worsen over weeks. Leaks are primarily caused by fatigue in the hose assembly, aging O-rings, wear caused by vibration, overpressure events, improper fittings or crimping, and other factors. Therefore, it is important to select the appropriate hoses and fittings based on the system’s operating pressure and implement appropriate safety systems.

Why do hydraulic leaks occur in plastic injection molding machines?

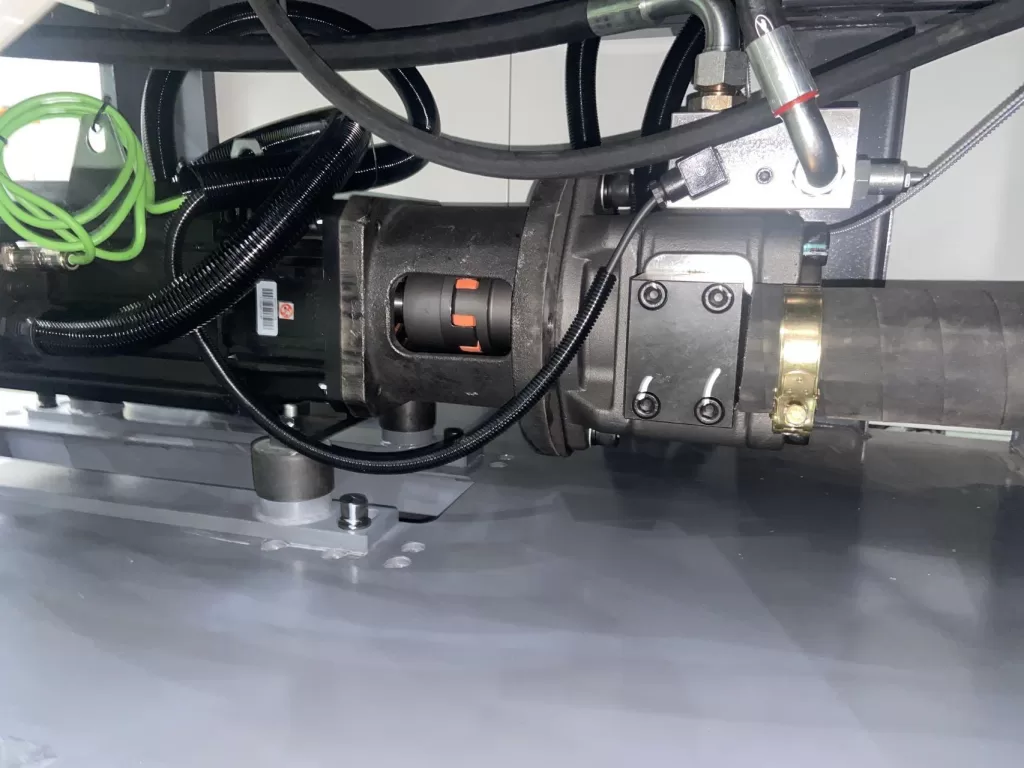

Hydraulic lines in plastic injection molding machines are subject to various stresses that accelerate wear. Examples include vibration from the toggle and ejector pins, pressure spikes during injection, high ambient temperatures in the platen area, and frequent mold changes that require hose movement. Common causes of leaks include:

- Hose fatigue and aging. Hoses deteriorate from repeated flexing and heat aging. Rubber and polymer hoses can harden, crack, or internally delaminate, especially near hot platens or exhaust ports.

- Improper specifications. Using hoses or fittings that are not rated for the working pressure can lead to premature failure.

- Field assembly or poorly crimped ends can cause leaks.

- Improper routing and inadequate strain relief. Hoses that rub against sharp edges, pass through moving parts, or are twisted can wear or internally break.

- Reused or misthreaded fittings, the use of incorrect sealants, or flange wear on ORFS fittings can all lead to leaks at the fitting.

- Component failure. Cracked fittings, corroded manifolds, or damaged cylinders can appear to leak from the hose.

- Overpressure events and cavitation. Pressure spikes can stress the hose wall. Cavitation can cause pitting in metal components, leading to leaks.

By correlating the timing of symptom onset with the failure mode, you can quickly identify the possible cause. For example, leaks that occur only after a long production run can indicate thermal degradation; leaks that occur after a mold change can indicate routing or strain issues.

Utilizing Inspection Technology for Inspection

Early detection of hydraulic line leaks can reduce downtime and prevent safety incidents. Therefore, a layered inspection strategy should be adopted for plastic injection molding machines—starting with low-cost visual inspections and upgrading to diagnostic tools as necessary. Visual inspections can be performed daily or before a shift to check for moisture on hose ends, fluid accumulation around fittings, discoloration on the boots, or streaking on the manifolds. Check the fluid level in the reservoir and note any unexplained drips. Then, wipe the suspected area, run the machine briefly, and check for fresh oil. This “clean start” approach can help find slow leaks. Also, note whether oil drips run along the hose or frame before dripping onto the floor.

Ultrasonic leak detection can also be performed. Micro leaks generate ultrasonic waves when pressurized. Handheld ultrasonic detectors can scan fittings and joints without stopping the machine and can find leaks that are invisible to the naked eye. They are particularly useful in noisy factories. Contamination and oil analysis are also necessary. Metallic wear particles or moisture in the oil can accelerate seal wear. Regular oil analysis and particle counting can help identify systemic issues that increase the risk of leaks.

Emergency Isolation and Safe Temporary Repairs

When a hydraulic leak occurs on a plastic injection molding machine, safety and control measures must be prioritized before attempting repairs. When a leak occurs, you must immediately stop the fluid loss, eliminate the potential hazard, and maintain production integrity before performing repairs. First, lock out and tag out the machine, shut down the machine, and control electrical and hydraulic power according to the LOTO procedure. Tag out and clearly sign the machine. Next, place absorbent pads and a drip pan under the leak, release any residual pressure according to the machine-specific procedure, and observe for 15-30 minutes. Where feasible, isolate the leaking circuit by closing the shutoff valve or switching to a redundant circuit. For hoses leaking at joints, seal the line with a rated blind fitting or temporarily replace it with a certified spare fitting.

For very low-pressure leaks, using a rated emergency clamp or hydraulic hose patch sleeve according to the manufacturer’s instructions can be a short-term mitigation measure. At the same time, the component is removed from the ground for appropriate repair. Then, document the incident, including the plastic injection molding machine ID, location, estimated leak rate, and any temporary measures taken. Notify production planners and the safety team, and schedule an inspection during the next scheduled downtime.

Replacing Plastic Injection Molding Machine Hoses, Fittings, and Seals

Repairing a plastic injection molding machine can restore its reliability and safety. The correct approach is to replace the faulty component with the correctly specified part and install it according to validated procedures.

The first decision to make is whether to replace or repair a hydraulic hose. For hydraulic hoses, it is recommended to replace the entire hose assembly, including new fittings and crimped connections, rather than attempting to cut and install the hose in the field. The hose’s inner layer may delaminate, and hidden damage often extends beyond the visible fitting. Fittings with damaged threads or sealing surfaces should be replaced. You should replace damaged seals and O-rings at the connector with materials suitable for the fluid and temperature.

To determine the correct part, match the hose’s working pressure and temperature ratings to the machine’s maximum working pressure and temperature, allowing for an appropriate safety margin. Then, confirm fluid compatibility and use the correct threads. Before assembly, clean all mating surfaces and wipe them with a lint-free cloth. Lubricate the O-rings with a compatible hydraulic fluid. Replace the hose to the appropriate length, avoiding excessive slack but never stretching it. Refill with clean, filtered hydraulic fluid and bleed the air as needed. Repairs performed according to these standards can minimize the likelihood of recurrence.

Implement a preventive and proactive maintenance plan.

For plastic injection molding machines, establish a practical program centered around inspection, replacement, and continuous improvement. Conduct daily visual inspections for leaks and fluid reservoir levels, weekly checks on critical hoses and fittings, and monthly detailed inspections, including thermal scans and ultrasonic inspections. Use a standardized inspection checklist to record hose condition, signs of wear, clamp integrity, and hose labels. For high-load injection molding, inspection frequency should be increased.

Replace hoses within their useful life, not just when a failure occurs. Maintain the recommended replacement interval based on operating hours, cycles, and environmental conditions. At the same time, maintain a stockpile of critical spare hoses, fittings, seals, and a small supply of OEM-certified hoses. Maintenance personnel should also be trained in hydraulic safety, LOTO procedures, proper crimping inspections, and the use of diagnostic tools. After each leak incident, conduct a root cause analysis and implement corrective actions, including procedural and design changes.

Proactive Detection Prevents Downtime

Effective handling of hydraulic line leaks in injection molding machines is both a safety issue and a way to reduce downtime and quality losses. Timely and accurate testing, strict adherence to the emergency procedure of powering off, depressurizing, and sealing, and the use of proper assembly pressure testing procedures can significantly reduce recurring failures and extend equipment life. Proactive leak detection and certified repairs can reduce safety incidents, lower scrap and pollution costs, and prevent downtime.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/09/12

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/09/12

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/09/12

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/09/12

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar