How to integrate the injection molding robot with the injection molding machine control system?

2025/09/17 By le zhan

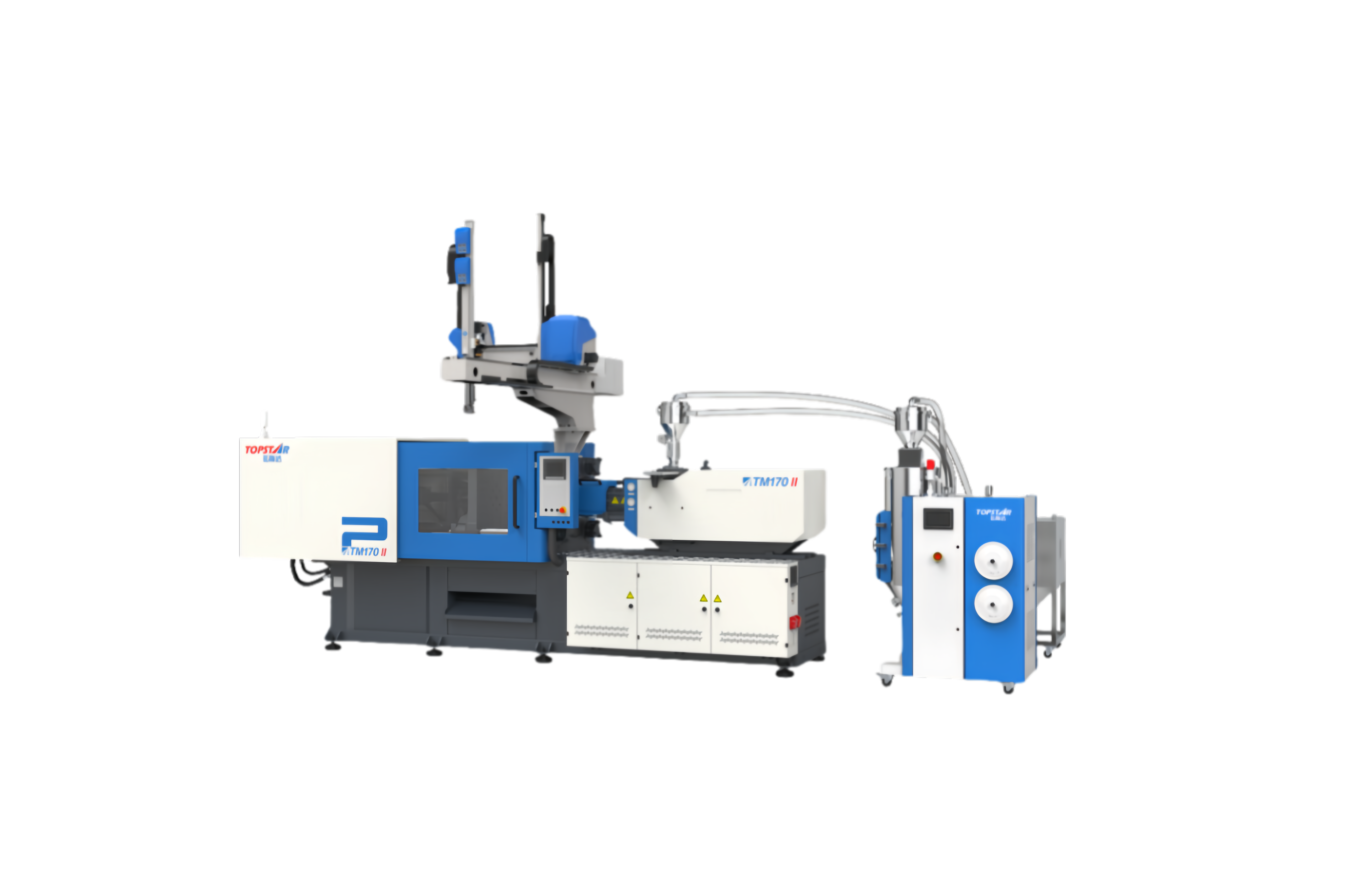

Integrating an injection molding robot with the injection molding machine control system transforms the two independent devices into a coordinated production unit, increasing output, improving part quality, and reducing cycle time variability. As an injection molding robot manufacturer, Topstar uses an open underlying control system architecture to enable the injection molding robot and injection molding machine to share a native “language,” making the device connection an extension of the control system rather than a fragile communication link.

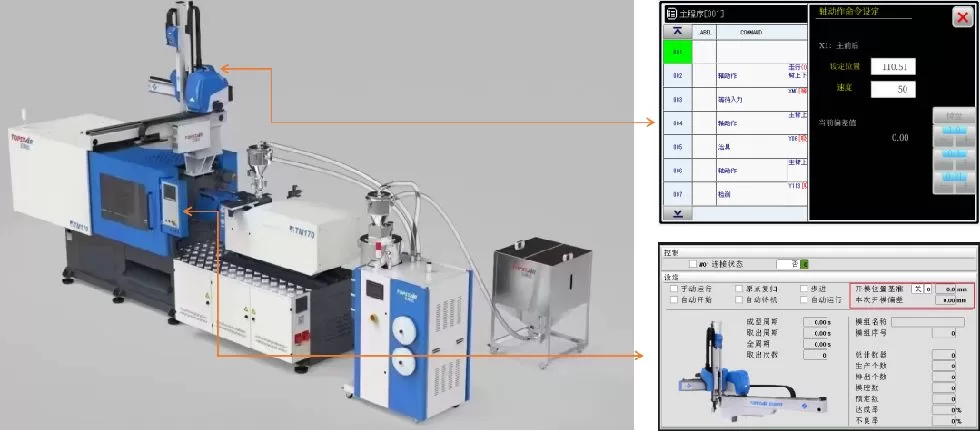

This allows them to respond to host signals for integrated operation, automatically optimizing the removal process in real time during machine switching and the holding pressure phase, thereby improving injection molding efficiency on the production line. The system’s openness also provides significant operator convenience. Technicians can use a handheld teach pendant to modify program sequences, servo parameters, and mechanical parameters, or update application code to explore optimal automation strategies for new molds and processes.

Determining the Integration Architecture and Communication Protocol for Injection Molding Robot Operation

For injection molding robots, deterministic, low-latency interfaces with clear signal and data point mapping are preferred. Traditional approaches use hardwired discrete input/output (I/O) for safety-critical interlocking, while relying on fieldbuses or industrial Ethernet for high-level coordination. Topstar integrates a unified communication language and control system, making it open and accessible. This allows the injection molding machine to call robot functions through the same control system programming environment. This eliminates translation layers and simplifies program modifications.

For high-speed, tightly synchronized cells, EtherCAT or direct real-time Ethernet connections are preferred because they provide sub-millisecond determinism. In this configuration, the injection molding robot controller subscribes to the machine’s real-time tracking. This is particularly useful for advanced switching strategies based on cavity pressure. Instead of using a fixed screw position, the injection molding machine publishes measured cavity pressure, and the injection molding robot waits for a gating signal to initiate extraction, minimizing flash and ensuring consistent packing pressure.

Injection Molding Robot Synchronization Strategies

Synchronizing the injection molding robot with the injection molding machine control system is a critical technical decision. Traditional systems use position switching, switching the press from velocity mode to packing mode at a preset screw position, then triggering the robot based on a timed delay or discrete “mold open” output. This approach works well for stable processes, but can become less stable when resin viscosity, ambient temperature, or mold wear alter the cycle dynamics.

Topstar’s pressure-based synchronization strategy uses in-cavity or nozzle pressure sensors to trigger switching and notify the injection molding robot when the cavity has reached the holding state and is safe for extraction. For example, when the control chart indicates a successful hold, the injection molding machine’s control system can issue a corresponding signal, and the robot then performs a precisely timed pick to avoid impacting the semi-cured part. Event triggers such as “First cavity gated,” “Filling complete,” or “Mold closed and locked” can then be displayed, and the robot executes the corresponding subroutine. Topstar’s open architecture allows operators to reassign or adjust these event triggers from the same human-machine interface, creating flexible sequences tailored to part geometry.

Safety, Guarding, and Standards Compliance for Integrated Cells

Safety is an essential element when integrating an injection molding robot into a production cell. The robot and injection molding machine must provide consistent safety features to protect personnel while not unduly limiting production output. We begin with a comprehensive risk assessment based on ISO 12100 and apply relevant standards, such as ISO 10218 for industrial robots and ISO 13849 for safety-related control systems, as well as region-specific regulations.

We determine whether the cell will operate in guarded mode with fixed fencing, light curtains, interlocking doors, and a safety PLC, or in collaborative mode with speed and force limitations. For high-speed, high-volume production, guarded cells remain the standard, as they achieve the highest cycle performance while preventing human contact. Safety signals are integrated at the hardware and controller levels, ensuring the injection molding machine’s “safe move” state is interlocked with the robot’s safety-rated inputs, and that both devices use the same safety PLC or certified safety network instructions to enter the safe state.

Quality Inspection and Data-Driven Traceability

One of the key advantages of tightly integrating the injection molding robot with the machine control system is the ability to embed quality assurance directly into the process. Vision systems and in-process measurement capabilities enable the robot to perform orientation correction, presence checks, and basic dimensional inspections within the same cycle, reducing manual inspection and providing traceability for each part. A vision system enables the robot’s end-of-line automated tooling (EOAT) to pick up parts, bring them to a camera, and then maintain that position. At the same time, the machine or local processor performs inspection. In Topstar’s integrated architecture, inspection results can automatically trigger real-time process adjustments: if a cavity consistently produces parts that don’t meet specifications, the host computer can adjust the injection speed, holding pressure, or temperature setpoints to compensate, or it can initiate preventive maintenance procedures or mark the tool for cleaning.

Real-Time Synchronization, Automatic Optimization

Topstar’s open underlying control system addresses this issue by creating a native language for the injection molding robot and machine, enabling real-time synchronization, automatic optimization, and operator-friendly adjustments. Whether you’re an SME or a large injection molding manufacturer, this approach transforms integration from a challenge to a competitive advantage. By prioritizing an open architecture, manufacturers can achieve 15-25% efficiency gains, reduce costs, and adapt to future process changes, all while staying ahead of the curve in this rapidly evolving industry.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/09/17

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/09/17

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/09/17

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/09/17

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar