How to reduce cycle time fluctuations through injection molding control strategies?

2025/09/03 By le zhan

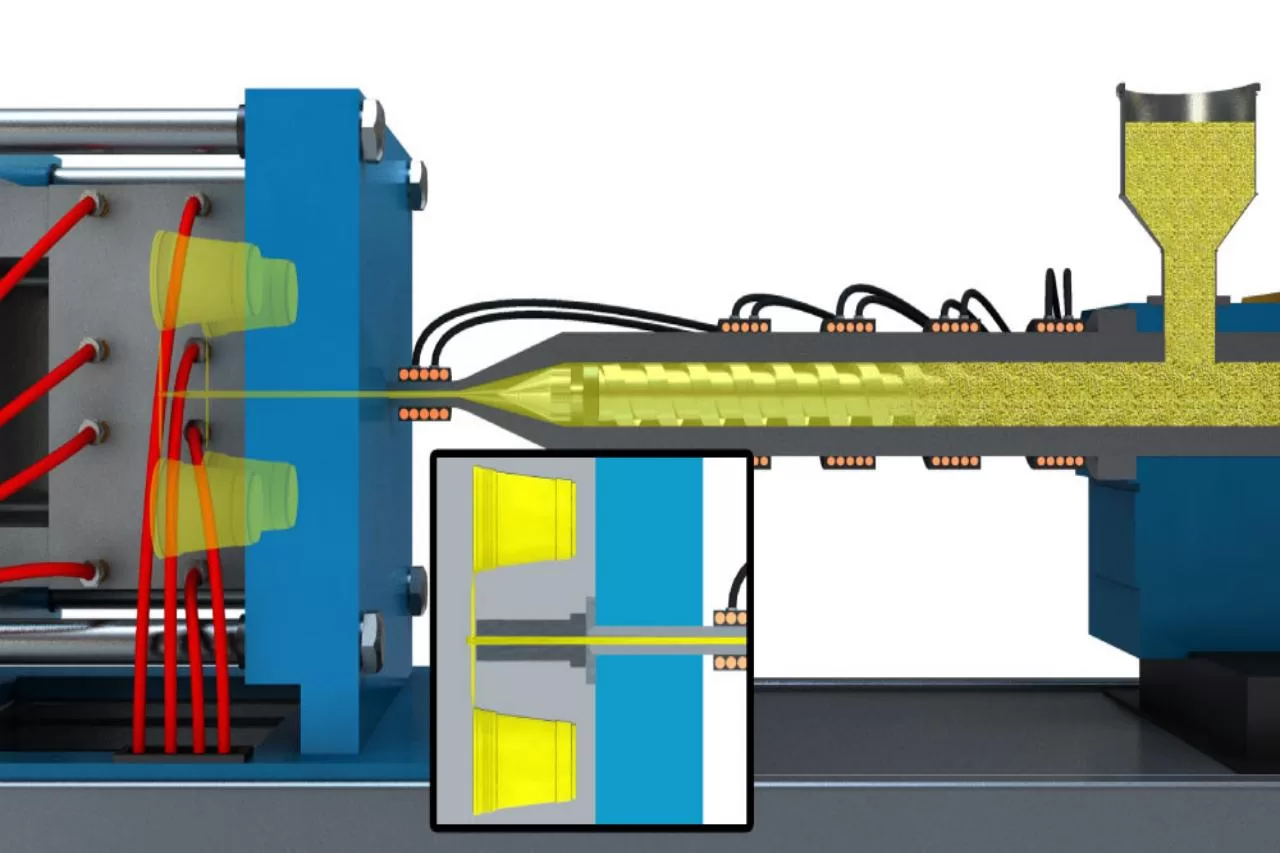

Achieving consistent injection molding cycle times hinges on translating every variable that influences the cycle—melt quality, cavity filling and packing, thermal conditions, mechanical motion, and material feed—into standardized, measurable, and controllable actions. When you replace manual adjustments and guesswork with closed-loop control, adaptive setpoints, and integrated monitoring, cycle-to-cycle variability decreases and production becomes predictable. Crucially, today’s injection molding machines aren’t passive presses; they’re platforms for control strategies. For example, Tostar injection molding machines combine a unified control system, precise position and pressure sensors, and deterministic motion control, enabling engineers to implement multi-step speed/pressure profiles, injection compression, and precise mold parallelism control. In practice, this capability allows you to execute optimized injections, complete filling and packing with minimal overpressure or underpressure, cool at a predictable rate, and only open the mold when the measured part solidification meets the specified standards, thereby achieving consistent cycle times.

Using Instrumentation and Real-Time Feedback to Control Variation in Injection Molding

Reducing cycle time variation starts with measurement. Without measuring the events that determine when it’s safe to open the mold, you’ll be forced to rely on conservative, time-based waits, which can be long and erratic. Therefore, the primary control strategy for stabilizing cycle time is to instrument the process so that machines, such as the injection molding machine, can act based on physical data. This involves installing cavity pressure sensors on the injection molding machine, as well as multiple thermocouples at strategic locations in the mold, barrel, and nozzle, along with thermistors and shot weight sensors. When cavity pressure replaces timer-based V/P switching and holding pressure decisions, the cycle will respond to the actual filling behavior of that shot, adapting to resin batch variations, ambient temperature drift, and subtle outgassing differences.

Similarly, installing mold temperature sensors and utilizing closed-loop temperature controllers can minimize thermal excursions that may lead to slow cooling or sudden overheating. Real-time feedback also enables the injection molding machine to compensate adaptively: it can fine-tune the injection speed to maintain a target cavity pressure rise rate or delay the mold opening until the cavity pressure profile and thermocouple readings indicate sufficient solidification. As a result, the production line moves from a fixed-duration cycle to a conditional cycle, narrowing the gap between safety and speed.

Applying Control Strategies to Stabilize the Injection Molding Cycle

Once measurement is in place, the next step is to apply control strategies to stabilize critical stages of the cycle proactively. Closed-loop control of injection and cavity pressure during filling and packing is fundamental. Unlike switching from speed to pressure based solely on time or screw position, cavity pressure-guided V/P switching enables the machine to sense when the cavity is full and switch to packing immediately. This eliminates under- and over-packing, reducing the need for large safety margins in packing time.

Another effective strategy is multi-step packing profiles, which apply a higher initial packing pressure to compensate for part shrinkage and then gradually reduce the pressure to avoid causing birefringence or flash. An injection molding machine with a multi-step pressure profile and fast servo response will precisely maintain each stage, eliminating pressure fluctuations that can prolong the cycle due to rework or scrap inspection. Furthermore, temperature compensation schemes that adjust barrel and mold set points based on ambient conditions can maintain stable melt viscosity and cooling rate, thereby reducing the time distribution required to reach the “solid” state.

Synchronizing Platens, Screws, and Auxiliary Axes for Speed and Repeatability

In many factories, inconsistent or unoptimized motion profiles, such as slow mold opening and closing, erratic ejection timing, or mismatched robot handoffs, can lead to backlash and affect cycle duration. Therefore, a strategic approach to reducing cycle time variation involves precisely coordinating the motion of machines. Topstar supports the integration of injection molding machines and peripheral injection molding equipment through a unified, proprietary control system. Precisely position-controlled platen drives ensure the mold closes with consistent parallelism and clamping force throughout each cycle. A forward platen design and a center-clamping strategy reduce platen deflection and improve parallelism under varying clamping loads, thereby improving venting consistency and reducing air entrapment fluctuations.

Synchronizing auxiliary axes via deterministic fieldbus or direct I/O enables the injection molding machine to delay mold opening by fractions of a millisecond until cavity pressure or temperature thresholds are reached without affecting overall cadence. When motion and process control operate on a single timing basis and share diagnostic information, cycle-to-cycle repeatability is improved.

Design and document sequences that minimize unexpected situations

Poorly designed molds, inconsistent venting, or ambiguous gate geometry are root causes of transient behavior that control systems cannot always correct. Therefore, design molds to minimize thermal gradients and ensure repeatable venting, select gate and runner systems that promote predictable filling, and provide easily accessible locations for cavity pressure and thermocouple sensors. Beyond the design, lock down process recipes in the injection molding machine and manage them as controlled artifacts. Maintain versioned recipes that include injection profiles, multi-stage packing profiles, mold temperature maps, and acceptable cavity pressure characteristics. Protect critical recipe parameters with role-based access permissions and use recipe validation on the machine to reject non-conforming values, eliminating ad hoc operator changes. This reduces human-induced variability and ensures adherence to a validated, approved sequence when line changes are necessary.

A systematic approach to compressing and stabilizing cycle times through control strategies

Reducing injection molding cycle time variation requires more than a simple adjustment. First, instrument the process and transition from time-based to data-driven operations. When cavity pressure and temperature determine V/P switching and mold opening, cycle variability decreases dramatically. Then, apply control strategies to absorb fluctuations introduced by resin batch variations or environmental drift. Deterministic timing coordinates motion and auxiliary axes to eliminate jitter in mechanical sequences. Tooling and recipe specifications are enforced to maintain constant inputs to the drive control strategy. Finally, maintain performance through predictive maintenance and analytics, operator training, and clear acceptance criteria. Implementing these strategies and equipping the production line with high-performance equipment results in shorter cycle times, higher throughput, and more predictable output.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/09/03

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/09/03

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/09/03

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/09/03

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- injection moulding dryer

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar