How to solve the problem of poor back-pressure control in a plastic molding machine?

2025/11/14 By le zhan

Many manufacturers encounter the issue of poor back-pressure control in plastic molding machine, leading to average scrap rates of 8% to 12% and annual losses of tens of thousands of dollars per machine. Some packaging manufacturers have also scrapped defective bottles worth tens of thousands of dollars due to uneven wall thickness caused by unstable back pressure. Some automotive parts suppliers have experienced a 23% increase in customer returns due to parts deformation caused by unstable back pressure. To address these issues, we utilize control technology, optimize settings, and implement proactive maintenance. Topstar’s TMll series injection molding machines utilize a proportional back pressure system and multi-level settings to provide precision and ease of use, resolving the problem of poor back pressure control.

What is back-pressure control in a plastic molding machine, and why does it fail?

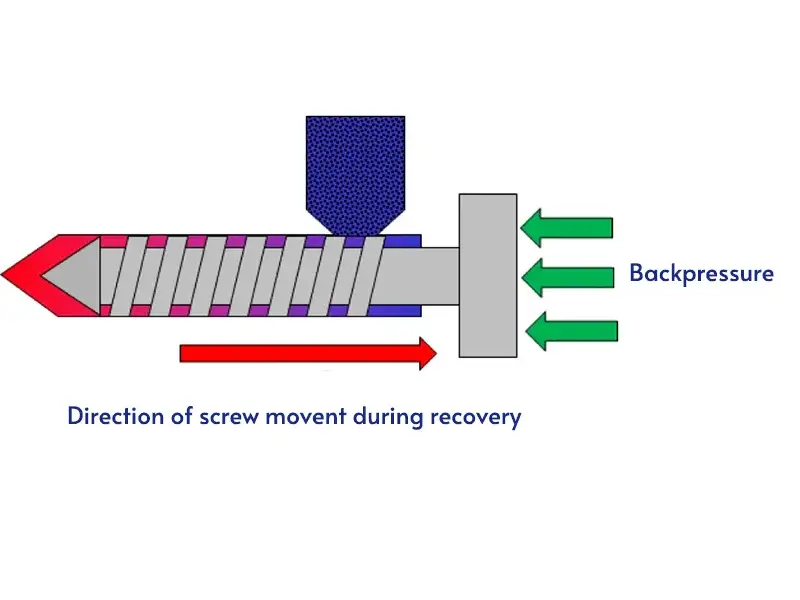

To address the issue of poor back pressure control, it is essential first to understand back pressure and its underlying causes. Back pressure refers to the resistance applied to the screw by the plastic molding machine during the plasticizing process. It ensures uniform resin melting, removes air bubbles, and ensures uniform mixing of additives. Poor back pressure control typically stems from three root causes:

Outdated manual control: Older plastic molding machines utilize manual valves to set back pressure, rendering it impossible to maintain a stable pressure during production. Even minor adjustments can lead to pressure overshoot or drop.

Worn parts, such as leaking hydraulic valves, faulty pressure sensors, or worn screw barrels, can all prevent accurate pressure transmission or detection, resulting in unstable performance.

Improper settings: Operators often set the back pressure too high or too low because they lack data on material requirements or machine capabilities.

The Cost of Poor Back Pressure Control in Plastic Molding Machine

Poor back pressure control not only causes waste but also affects all aspects of production, damaging profits. When back pressure is poorly controlled, unstable melt quality occurs. Too low or unstable back pressure can lead to bubbles, unmelted resin particles, or uneven color distribution in the melt. This results in shrinkage marks, voids, or streaks in parts, with 90% of parts being unsellable.

Furthermore, excessive back pressure can cause resin scorching. Too high a back pressure generates excessive heat, causing the resin to scorch and form a black, degraded layer that damages the parts. A plastic medical product manufacturer once lost tens of thousands of dollars due to a batch of products contaminated by charred resin, which had contaminated polycarbonate components. Simultaneously, extended cycle times occur, with operators frequently slowing down cycles to compensate for insufficient back pressure, leading to a 10-15% reduction in output. Furthermore, premature wear of the injection molding machine can occur; unstable pressure puts stress on the screw, barrel, and hydraulic system, shortening the lifespan of the plastic molding machine by 20-30%.

Proportional Back Pressure Control: Topstar’s Solution

The most effective way to solve poor back pressure control is to upgrade to proportional back pressure control, which is precisely the technology used in Topstar’s TMll series injection molding machines. Unlike manual or on/off control, proportional control enables precise, automated pressure regulation.

The TMll injection molding machine utilizes a proportional pressure valve to regulate back pressure in real-time. It responds to changes in resin viscosity, screw speed, and temperature, maintaining pressure within ±0.1 MPa for consistent results. Operators can set the desired back pressure through the TMll’s touchscreen interface, eliminating the need for manual knobs or guesswork. The system can store settings for different materials, so switching from PP to ABS takes only seconds, eliminating the need for hours of adjustment.

Furthermore, the proportional valve is more durable than manual valves, with a lifespan three times longer. TMll’s sealed sensors prevent resin dust and moisture damage, avoiding the drift problems common in older machines. One of our contract molding plants stated, “We used to spend two hours adjusting the back pressure every shift. With the TMll injection molding machine, we only need to set it once, and it remains stable.”

Multi-stage back pressure settings, precise control, improved plasticizing quality

The TMll plastic molding machine series takes it a step further with multi-stage back pressure settings, allowing you to adjust the pressure at different stages of plasticization. This level of control ensures optimal melt quality even for the most demanding materials:

- Stage 1: Low back pressure (0.5-1 MPa) prevents resin from burning when the screw begins to retract and draw in raw materials.

- Stage 2: Medium back pressure (1-3 MPa) Mixes additives and removes air bubbles without generating excessive heat.

- Stage 3: High back pressure (3-5 MPa) (MPa) homogenizes the melt, ensuring uniform density and flowability, thus guaranteeing consistent part quality.

For example, an injection molding plant producing glass fiber reinforced nylon used TMll’s multi-stage settings to reduce porosity by 92%. Their process engineer explained, “Glass fiber reinforced resin needs gentle melting but also thorough homogenization. TMll’s multi-stage control allows us to achieve both simultaneously, something our previous plastic molding machines couldn’t do.” This precision translates into improved plasticizing quality, resulting in a smoother, bubble-free, and more uniformly mixed melt, which produces parts that meet stringent tolerances and consistently pass quality inspections.

Calibration and Maintenance for Precise Back Pressure Control

Even the best proportional control systems require regular calibration and maintenance to achieve optimal performance. Pressure sensors can be calibrated quarterly, verifying TMll sensor readings using a certified pressure gauge. If deviations occur, adjustments can be made via the TMll’s touchscreen. Additionally, valves should be inspected every 6 months for leaks or wear on the proportional pressure valves.

Topstar’s TMll features easily replaceable valve cores, eliminating the need for costly hydraulic system overhauls. Annual Screw Barrel Cleaning: Worn or fouled screw barrels can affect pressure transmission. The TMll injection molding machine’s screw barrel features an easy-to-remove design, reducing maintenance time compared to comparable products. 50%. Furthermore, when changing resins, please test and store the optimal back pressure setting in the TMll’s memory. This avoids waste caused by repeated trials during changeovers.

Precisely and efficiently solve back-pressure control problems.

If you experience poor back pressure control, don’t worry too much. Topstar’s TMll series injection molding machines offer the simplest and most effective solution to back pressure control problems through their easy-to-use interface, precise proportional control, and multi-level settings.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/11/14

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/11/14

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/11/14

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/11/14

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar