Injection Molding of Flexible Materials: Precautions for TPU/TPE Processes

2025/11/07 By le zhan

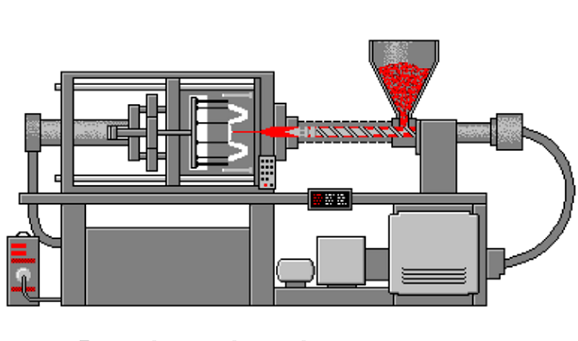

Two common mistakes are easily made when injection molding TPU/TPE: using injection pressures below 1400 kgf/cm² and using standard (non-nitrided) screws and barrels. TPU and TPE offer unparalleled flexibility and durability, but their unique flowability and abrasion resistance require specialized process control to achieve optimal results. Therefore, several key considerations must be taken into account when injection molding TPU/TPE materials, focusing on mandatory high pressure, nitriding of parts, and other critical steps designed to help you obtain consistent, high-quality parts.

Why is an Injection Pressure of 1400 kgf/cm² or Higher Required for TPU/TPE Injection Molding?

TPU and TPE have higher viscosity than rigid plastics like PP or ABS, meaning they are difficult to flow into the mold cavity. Therefore, injection molding processes for these materials require a minimum injection pressure of 1400 kgf/cm² on the injection molding machine, and often higher pressures for complex parts.

Low pressure (below 1400 kgf/cm²) can cause gaps in the mold because material cannot reach all cavities or thin-walled areas. One medical tubing manufacturer solved 80% of its TPU under-injection problems by increasing the pressure from 1200 kgf/cm² to 1500 kgf/cm².

Additionally, high-pressure compacts TPU/TPE, eliminating air bubbles, and ensures consistent overall flexibility of the part. Under-pressurized parts often have soft spots or brittle edges. For parts with complex details (e.g., textured grips) or long flow paths, increase the pressure to 1600–1800 kgf/cm². Use pressure profiling to avoid shear damage—TPU/TPE may degrade if the pressure peaks are too high.

Use nitrided screws and barrels in injection molding machines.

TPU and TP are abrasive and can cause excessive wear on the screws and barrels of standard injection molding machines. This wear leads to uneven plasticization, material degradation, and frequent part replacements. To ensure reliable TPU/TPE injection molding, always use nitrided screws and barrels in your injection molding machine.

What is nitriding? Nitriding is a heat treatment process that creates a hard, wear-resistant surface on steel parts. Nitrided surfaces resist the wear of TPU/TPE, extending screw/barrel life by 3-5 times compared to standard chrome-plated parts. Nitrided parts maintain consistent melt quality by preventing material buildup and ensuring uniform flow. One automotive parts factory reduced the discoloration rate of its TPU parts by 90% after upgrading to nitrided screws. Never use bimetallic screws for ordinary TPU/TPE—it is both wasteful and expensive. Nitrided screws strike a perfect balance between durability and cost, making them suitable for flexible materials. Topstar’s service team frequently observes this: “Factories using ordinary screws to secure TPE materials need to replace them every 6 months. Factories using nitrided screws, however, experience no problems for 2-3 years.”

TPU/TPE Material Drying Precautions

TPU is highly hygroscopic; even small amounts of moisture can disrupt the injection molding process, leading to bubbles, cracks, and reduced part strength. TPE varies depending on grade; some grades are non-hygroscopic, but most perform better after drying. Please follow these steps:

TPU Drying: Dry in a dryer at 80–100°C for 2–4 hours. Use a hopper dryer with a dew point of -40°C to ensure complete removal of moisture. Please do not skip the drying step, as we have found that up to 20% of TPU parts are defective due to undried material.

TPE Drying: Thermoplastic olefin TPE is non-hygroscopic, but styrene-based TP and TPE blends stored in humid environments may require drying at 60–80°C for 1–2 hours.

The best storage method is to store TPU/TPE products in a sealed bag containing desiccant. If opened, air dry immediately, as moisture will be absorbed within hours in humid environments.

Temperature Control Techniques for TPU/TPE Processes in Injection Molding

Temperature directly affects the flowability, flexibility, and part quality of TPU/TPE. Unlike rigid plastics, even small temperature fluctuations (±5°C) can cause serious problems. Temperature can be controlled as follows:

Melt Temperature:

TPU: 160–220°C. Temperatures above 230°C can lead to thermal degradation (yellowing, brittle parts).

TPE: 130–190°C (varies depending on the matrix polymer; styrene-based TPEs require lower temperatures, while olefin-based TPEs require higher temperatures).

At the injection molding machine, maintain the mold temperature at TPU at 30–60°C and TPE at 20–40°C. Higher mold temperatures improve flowability but increase production cycles; lower temperatures accelerate cooling but may cause shrinkage marks. Utilize water cooling to maintain a consistent temperature in the mold cavity. Also, maintain the nozzle temperature 5–10°C higher than the melt temperature to prevent material solidification.

Post-molding treatment to maintain TPU/TPE properties

TPU and TPE parts are flexible but prone to deformation after molding. Proper post-molding treatment ensures that they retain their shape and properties. Trim or pack only after the parts have completely cooled. Premature cooling can lead to deformation. Trim the gate with sharp, clean tools. Dull blades can tear TPU/TPE, resulting in rough edges and reduced part strength. For high-volume production, use a die-cutting machine for clean, consistent cuts. Lay parts flat in a cool, dry place. Avoid stacking heavy objects on TPU/TPE parts to prevent deformation under pressure. Use breathable packaging to prevent moisture buildup.

TPU/TPE Process and Core Material Considerations

67% of common problems in TPU/TPE injection molding can be solved by prioritizing two key factors: using an injection pressure of 1400 kgf/cm² or higher, and equipping the injection molding machine with a nitriding screw and barrel. When combined with proper drying, temperature control, mold design, and post-processing, stable, high-quality flexible parts can be achieved.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/11/07

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/11/07

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/11/07

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/11/07

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar