How to solve the accuracy deviation of the mold opening position in a plastic injection molding machine?

2025/11/21 By le zhan

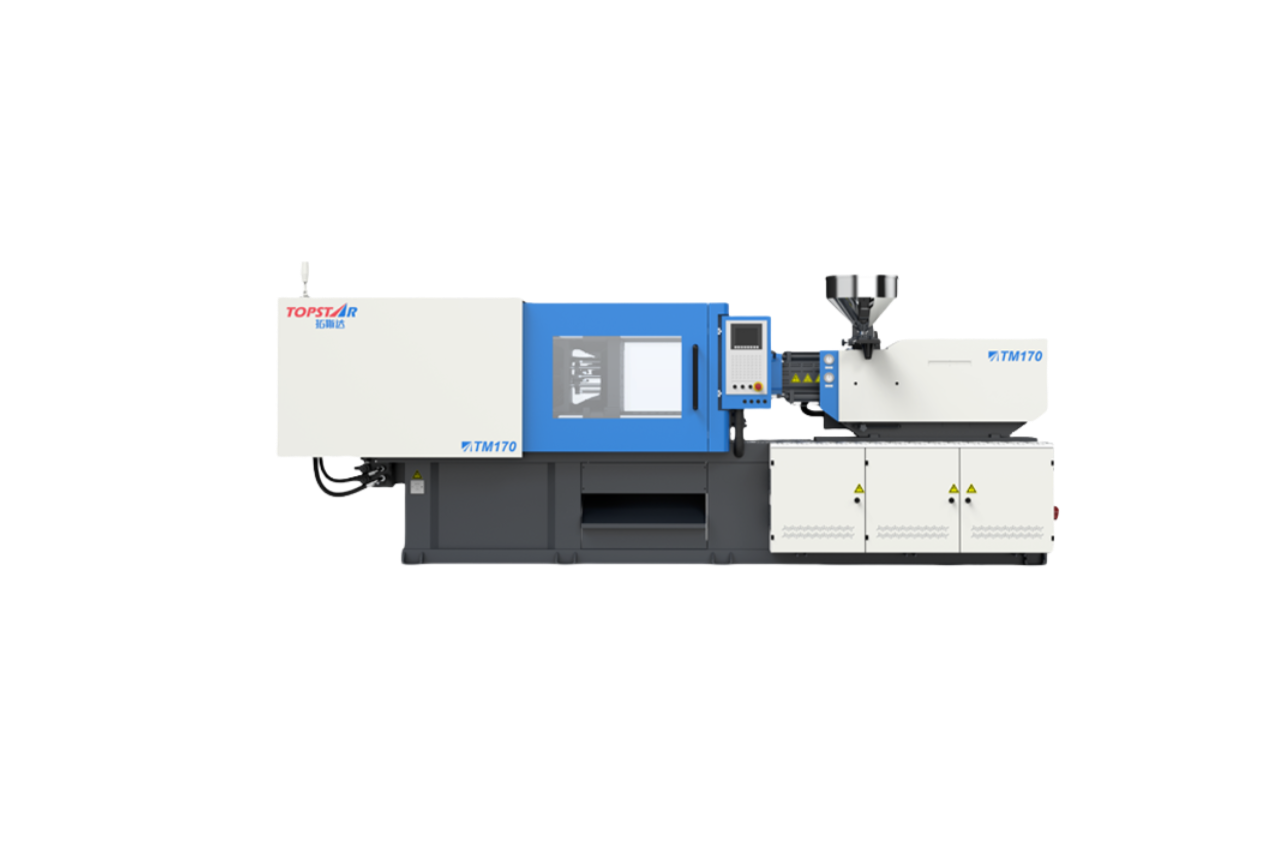

When the mold opening position of a plastic injection molding machine deviates by 3 mm per cycle, it causes flash (excess plastic) on precision parts, rendering them unusable. In industries such as medical, automotive, or electronics, part tolerances can be as small as ±0.5 mm, and even a 1 mm deviation can have serious consequences. To better address this issue, Topstar employs a new inclined elbow layout to accommodate extra-large mold openings, achieving mold opening position accuracy of less than +1 mm and ensuring rapid, stable mold movement.

What is Mold Opening Position Accuracy Deviation in Plastic Injection Molding Machine?

To solve the problem of mold opening position accuracy deviation, it’s essential to understand what it is and why it’s crucial. Simply put, mold opening position accuracy deviation is the failure of the moving platen of a plastic injection molding machine to stop at the target position in each cycle precisely. Deviations can range from 0.5 mm to 5 mm—regardless of size, they will interfere with the molding process.

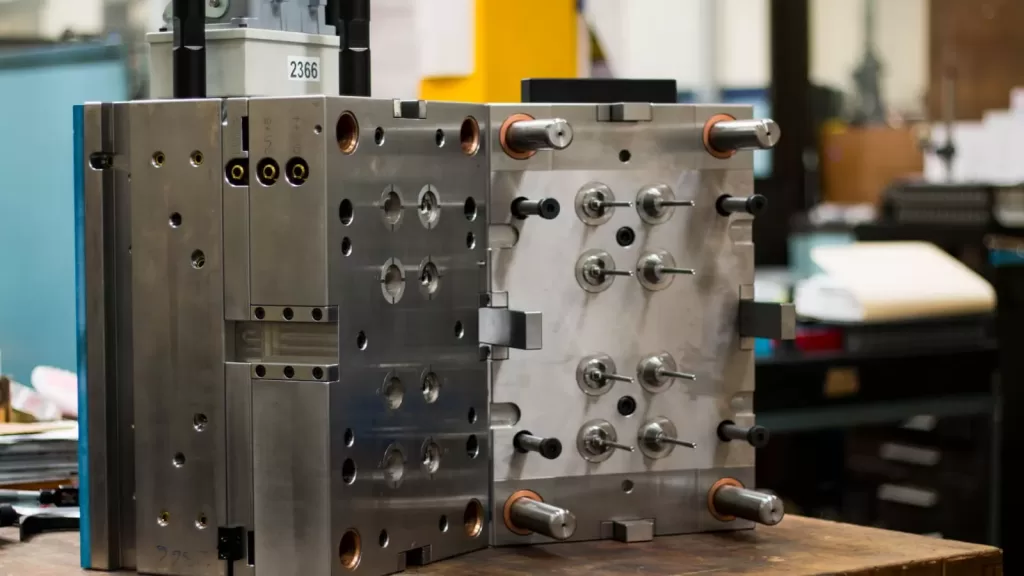

If the platen stops too short (insufficient opening), the mold cannot wholly separate, leading to parts sticking or tearing. If the pressure plate stops too far (opening too large), misalignment can occur during mold closing, leading to flash, warping, and even mold damage. Therefore, for precision parts, even a 1mm deviation can cause dimensions to exceed tolerances. Mold opening accuracy is fundamental to ensuring stable part quality; if the pressure plate doesn’t stop at the correct position, every step from injection molding to cooling will be affected.

Why do traditional mold opening mechanisms fail?

Traditional plastic injection molding machines rely on outdated toggle or hydraulic-cylinder layouts, making it challenging to guarantee accuracy—especially in large molds or high-volume production. Uneven force distribution occurs, and the old toggle mechanism design applies uneven pressure to the moving pressure plate, causing it to “wobble” during opening and closing. This wobbling leads to inconsistent stop positions. Furthermore, limited adjustability means most traditional injection molding machines cannot accommodate ultra-large molds. The pressure plate movement becomes unbalanced, leading to increased deviations.

Additionally, wear-induced drift occurs; sliding guides and hydraulic components wear over time, causing system gaps. Even slight wear (0.1 mm) can lead to significant deviations. Furthermore, their slow response time—hydraulic systems requiring 5-10 milliseconds to adjust position—is too slow to correct deviations during cycles.

The Hidden Costs of Mold Opening Deviations in Plastic Injection Molding Machines

Mold opening position accuracy deviations not only cause scrap but also impact the entire production process, increasing production costs. Scrap and rework are the most obvious costs. A consumer electronics mold manufacturer in Texas calculated that parts scrapped due to a 2 mm deviation waste 220 pounds of resin per month—a material fee of $3,300 alone. Reworking repairable parts requires an additional 8 hours of labor per week.

Additionally, mold damage can lead to misalignment during mold opening, causing wear on the mold cavity, core, and guide pins. Custom molds cost between $50,000 and $200,000, and deviations can shorten their lifespan by 30% to 40%. It also results in excessive downtime, with operators frequently needing to stop production to adjust the machine, recalibrate, or repair stuck molds.

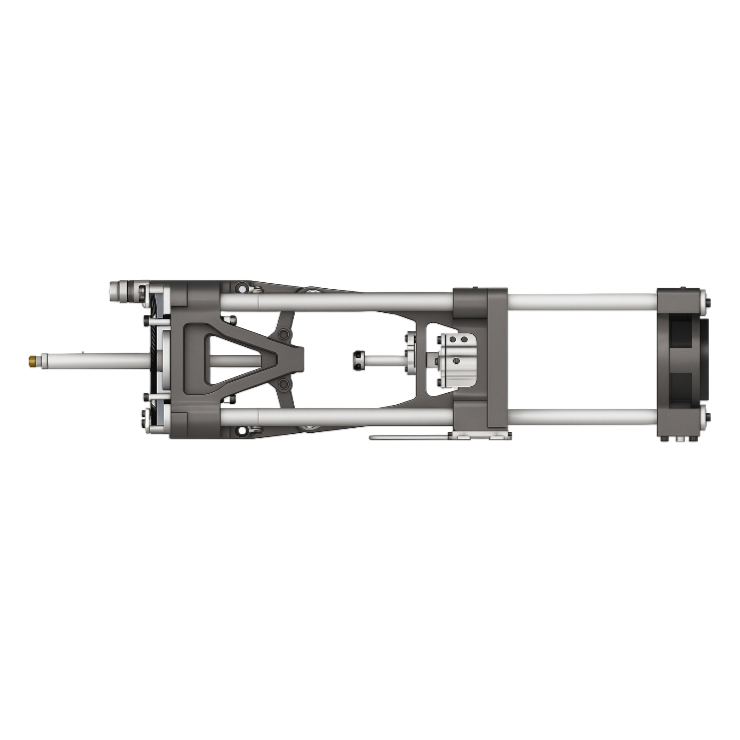

New Inclined Row Machine Layout Toggle – A Solution for Precision < +1mm

To address the issue of mold opening position accuracy deviation, Topstar has designed a new inclined row layout for the machine toggle. This layout allows for more even force distribution across the moving platen, eliminating wobbling. Every point on the platen moves in perfect synchrony, ensuring a consistent stopping position every time. Simultaneously, it allows for greater adjustability of ultra-large molds. Unlike traditional toggle structures, this inclined elbow layout can accommodate molds up to 3 meters in length. It uses an adjustable elbow angle to balance platen movement, enabling effective operation even with ultra-large or asymmetrical molds.

In Topstar’s tests, this layout achieved mold opening positioning accuracy of less than ±1 mm, far exceeding the industry average of ±2mm. This level of accuracy meets the most stringent tolerance requirements. The rigid structure of the elbow reduces vibration during opening and closing, shortening the cutting cycle time by 5-8% and enabling fast, stable movement in plastic injection molding machines.

Maintenance Tips for Maintaining Mold Opening Accuracy

Even with Topstar’s inclined row machine toggle layout, proper maintenance can ensure your plastic injection molding machine maintains an accuracy of <+1mm for years. Lubricate the elbows quarterly with Topstar’s recommended grease to keep the moving parts running smoothly. Dry joints can cause friction and deviation. Also, check the linear guides monthly and wipe them clean to remove dust and debris. Inspect for wear and replace if necessary. Utilize monitoring cycle data; Topstar injection molding machines record mold opening position data. Review this data weekly to identify trends (e.g., gradual deviation). Address problems early to avoid costly downtime.

Completely Solve Mold Opening Deviation Problems

Mold opening position accuracy deviation in injection molding machines no longer needs to be a long-term problem. Topstar’s angled elbow layout design in plastic injection molding machines effectively eliminates deviation through uniform force distribution, a wide mold adjustment range, and an accuracy of less than +1mm, ensuring that every part meets tolerance requirements in every production cycle.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/11/21

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/11/21

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/11/21

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/11/21

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar