Injection Mold Machine Screw Selection Guide: Single Screw vs. Twin Screw Selection

2025/12/01 By le zhan

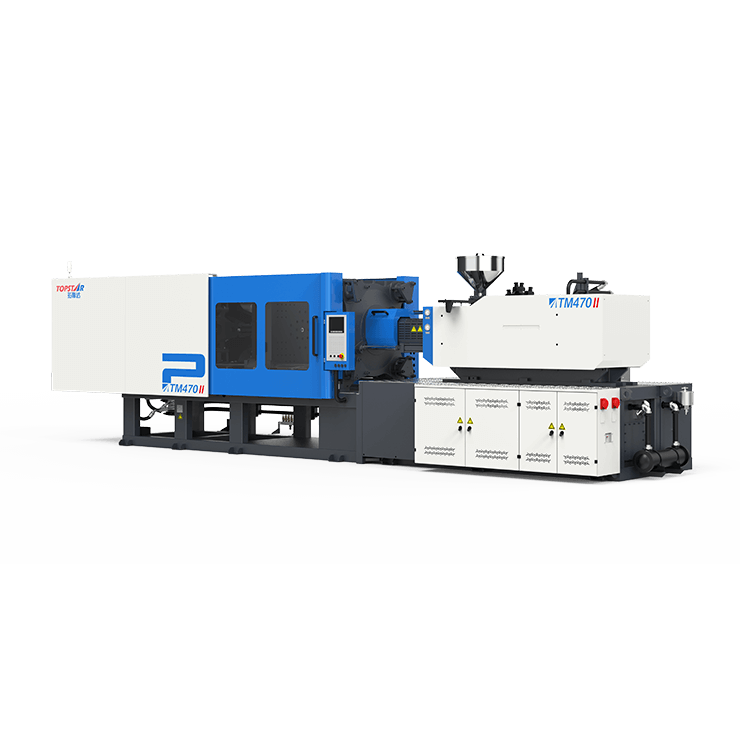

The screw in an injection mold machine primarily functions to melt, mix, and precisely inject plastic. Choosing the wrong screw can lead to scrap, delays, and material waste. Selecting the right screw ensures consistent quality and lower costs. The choice between a single-screw and a twin-screw injection mold boils down to one question: what material are you molding, and how are you molding it? Most injection molding machines on the market (90%) use single-screws—including all Topstar models—because they perform exceptionally well with mainstream materials and applications (PP, ABS, PE, etc.). In contrast, twin-screws are specialized tools for processing niche, complex materials.

The Difference Between Single-Screw and Twin-Screw Injection Mold Machine

Before delving into the selection process, let us demystify these two designs—confusing them can lead to costly mistakes we see every day. Both types of screws are located in the injection unit of an injection molding machine, rotating to transport plastic pellets from the hopper to the mold. Their differences lie in their structures, mixing capacities, and applications.

A single-screw, as its name suggests, is a helical screw located within a cylindrical barrel. It utilizes three key zones to process plastics: the feed zone (which draws in granules), the compression zone (which melts the plastic through heating and friction), and the metering zone (which mixes the molten plastic and pushes it into the mold). Its design is simple, reliable, and optimized for stable flow—suitable for most materials.

Twin-screw injection mold machines consist of two meshing screws that rotate in the same or opposite directions. The overlapping threads (helical ridges) of the screws produce intense shearing and mixing, making them ideal for mixing additives (such as glass fibers) or processing materials containing impurities (such as recycled plastics). They are larger, more complex, and require specialized injection mold machines, which is why they are used in only 10% of industrial production.

Single-screw injection mold machine—materials, applications, and industry standards

Single-screw injection mold machines dominate the industry for one simple reason: they can process 85% of the materials used in global manufacturing. Its simple and efficient design ensures stable melt quality, low maintenance costs, and short production cycles—which is why 90% of injection mold machines (including all Topstar injection molding machine series) use single-screw injection molding machines.

Suitable materials and applications for single-screw injection mold machines:

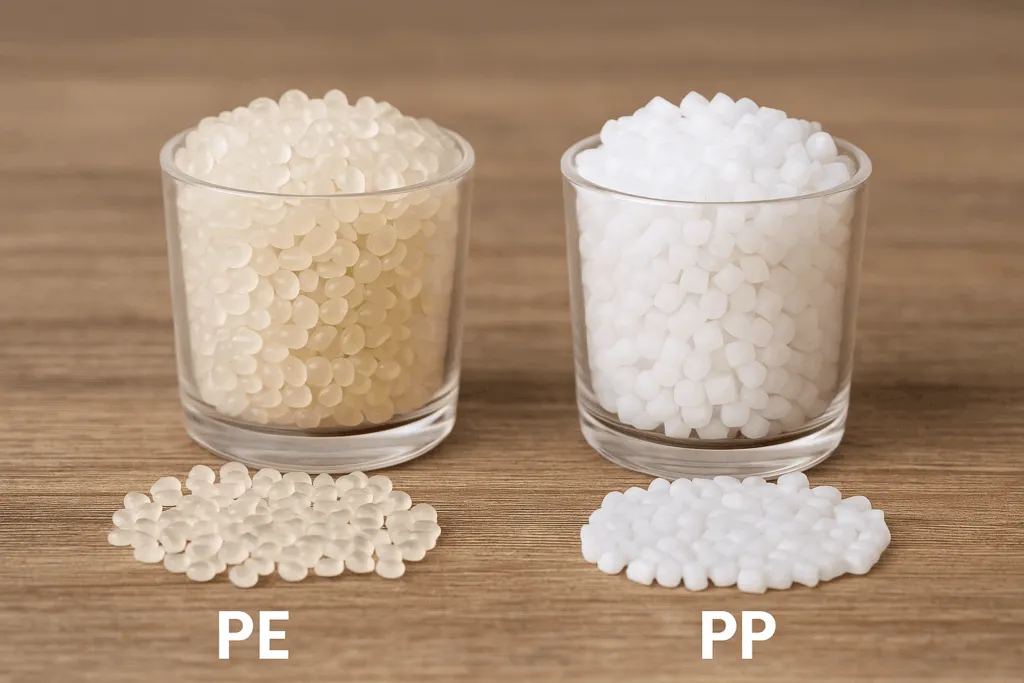

Common thermoplastics: PP (polypropylene), ABS, PE (polyethylene), PS (polystyrene), and PVC (rigid plastics). These materials have good flowability and do not require vigorous mixing.

Consumer goods: Toys, household appliances (e.g., plastic handles), and electronic product housings. Single-screw injection molding machines can provide the uniform wall thickness required for these parts.

Automotive interiors: Dashboard trim, door panels, and cup holders. Materials such as TPO (thermoplastic olefins) can be seamlessly processed with single screws.

Twin-screw—Advantages for Special Materials

Twin-screws are not “better” than single-screws, but somewhat different. They can solve specific problems that single screws cannot, but they also come with trade-offs that limit their applications.

Twin-screw injection mold machines excel at handling materials that require vigorous mixing, dispersion, or contamination resistance. Here are some of their key application examples:

Reinforced Composites: Glass fiber reinforced nylon, carbon fiber reinforced polyetheretherketone (PEEK), and mineral-filled polypropylene (PP). The interlocking screws of a twin-screw machine evenly distribute fibres, preventing fibre clumping and reducing part strength.

Recycled or Contaminated Materials: Post-consumer recycled (PCR) plastics containing small amounts of impurities. Twin-screw injection moulding machines break down impurities and evenly mix them, reducing defects.

Multi-Material Mixtures: Plastics mixed with additives such as flame retardants, colorants, or UV stabilizers. Twin-screw injection mold machines ensure even distribution, preventing “streaking” in colored parts.

However, twin-screw injection mould machines have significant drawbacks in most applications: they cost 2-3 times as much as single-screw machines, require specialised operators, and have cycle times 30% longer due to slower mixing speeds. Furthermore, twin-screw injection mold machines generate more heat, which can damage sensitive materials such as ABS or PC.

Injection Mold Machine Screw Selection: Five Key Factors

The choice between single-screw and twin-screw injection molding machines is not arbitrary; it is based on several specific factors. First, determine the type of material you are using. If you are using standard thermoplastics (PP, ABS, PE) or unreinforced materials, a single-screw is ideal. If you are using reinforced composites, PCR plastics, or multi-additive blends, a twin-screw may be necessary. Second, consider your tolerance requirements for the product parts. Parts with tight tolerances (±0.01 mm) or thin walls (less than 1 mm) require stable melt flow—a requirement that a single-screw can effectively meet. Inconsistent mixing ratios in twin-screw injection moulding machines can cause slight viscosity variations, leading to uneven filling.

Additionally, your high-volume production benefits from the faster cycle speeds of single-screw injection molding machines. The slower mixing speeds of twin-screw machines can cause a 20% to 30% decrease in output. Furthermore, the total cost of ownership for a single-screw injection molding machine is lower, with lower upfront and maintenance costs and a longer lifespan. Over a five-year operating cycle, the total cost of ownership for a single-screw injection molding machine is 45% lower than that of a comparable twin-screw injection molding machine.

Why do we design single-screws for 99% of applications?

All of Topstar’s injection molding machine series use single-screw machines. This is not an oversight, but a meticulous design based on 30 years of customer data and industry trends. We continuously improve our single-screws to outperform generic designs, even allowing for custom modifications to handle certain “twin-screw-only” materials.

We do not use “one-size-fits-all” screws. For low-viscosity PP materials, we design shallow threads to prevent backflow. For high-viscosity PC materials, we use deep threads for efficient material delivery. Additionally, the screws are electroplated with a hardness of HRC 60+. This makes them resistant to abrasive materials (such as 10% glass fiber reinforced polypropylene), extending their service life by 50% compared to uncoated screws.

Furthermore, the machining accuracy of each screw is controlled within ±0.005mm. This ensures a perfect fit between the screw and barrel, eliminating dead zones where plastics might scorch or degrade. Our single-screw design achieves ±2°F melt temperature stability—crucial for heat-sensitive materials like ABS. For customers requiring lightweight reinforcement (10-15% glass fiber), we add a mixing section (minor grooves on the screw threads) to the single screw to improve dispersion. This results in an average defect rate of only 1.2% for injection molding machines using single screws, significantly lower than the industry average of 3.5%.

Single screws are the most common and standard choice

Choosing the right screw is the most critical decision when purchasing an injection molding machine, and data clearly shows that for 90% of applications, a single screw is the correct choice. It is more economical, faster, more reliable, and optimized for most materials commonly used in the manufacturing industry (PP, ABS, PE, etc.). Twin screws also have their uses—for example, for reinforcing composites, recycled materials, and multi-additive blends—but they are specialized tools, not the default choice. At the same time, it is important to remember that when choosing a screw for an injection moulding machine, the material should guide your decision.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/12/01

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/12/01

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/12/01

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/12/01

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar