How to solve the problem of low production efficiency: Topstar’s molding machine to improve overall efficiency by 15%

2025/12/12 By le zhan

Inefficient injection molding operations are often caused by delays between steps, resulting in lower overall efficiency. For example, a slow-responding dryer causes the molding machine to be idle; drifting mold temperature controllers result in scrap. As a result, operators waste two hours a day switching between five different control interfaces. This lack of equipment coordination is the core of low production efficiency, and many companies still report that their existing injection molding machines cannot operate synchronously with upstream and downstream equipment. On average, injection molders lose 12% to 18% of potential output due to these bottlenecks.

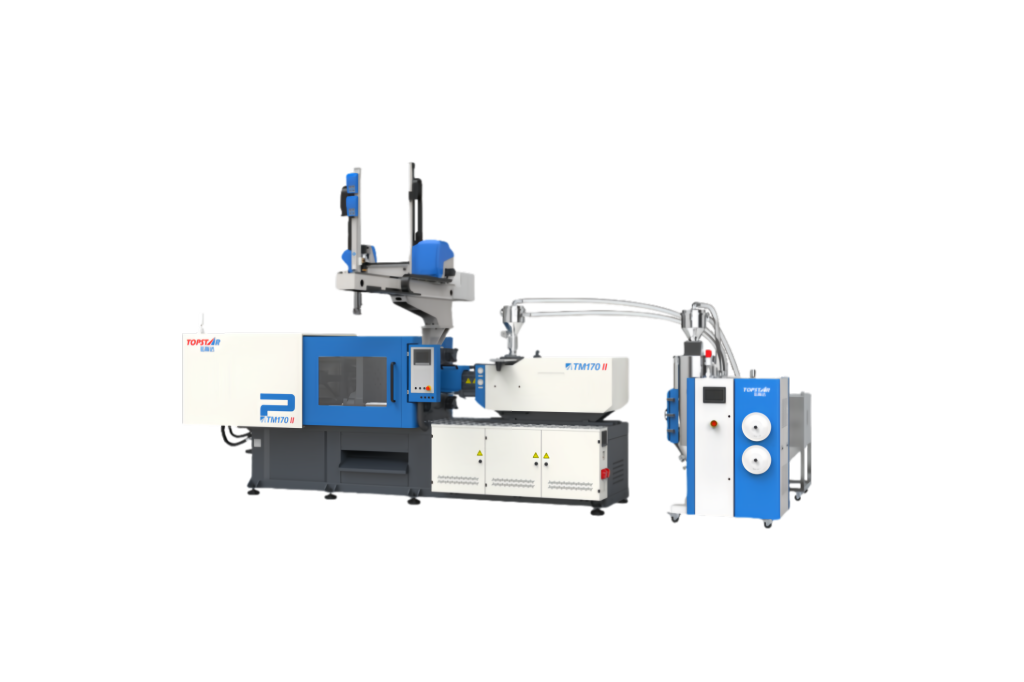

Topstar’s molding machines, with their integrated process design, enable a single control interface to link multiple devices, and through real-time communication feedback, achieve integrated control of the entire injection molding process, from material pretreatment and plasticizing to molding and demolding, ensuring seamless coordination between all equipment. This resulted in a 20% increase in servo power, a 20% increase in injection speed, and a 10% increase in screw speed, leading to a 15% improvement in overall injection molding efficiency.

Inefficiency in injection molding causes more than just slow production cycles

Most customers equate “inefficiency” with slow production cycles—but the real costs go far beyond the speed at which machines produce parts. Inefficient molding machines can have a ripple effect, hurting your profits in four ways, and outdated, isolated equipment cannot solve any of these problems.

First, there is unplanned downtime. Molding machines that cannot communicate with the dryer or mold temperature controller are often idle: if the dryer isn’t ready, the molding machine waits; if the mold overheats, the molding machine stops. Second, there’s a high scrap rate. When the molding machine is operating in a vacuum environment, even minor deviations can result in defective parts. Third, it leads to low labor efficiency. Operators spend 15% to 20% of their shifts switching between different control interfaces: adjusting the dryer on one screen, the injection molding machine on another, and the injection robot on a third.

What is the root cause? Traditional molding machines are independent tools, not part of an interconnected system. Topstar’s injection molding machines solve this problem by integrating disparate steps—material preparation, plasticizing, molding, and demolding—into a single, coordinated process.

Topstar’s Integrated Molding Machine Design

The key to Topstar’s 15% efficiency improvement lies in its integrated molding machine process design. Instead of treating the injection molding machine as a standalone unit, we’ve designed it as the “brain” of the entire injection molding unit, connecting all equipment (dryer, mold temperature controller, injection robot, etc.) through an intuitive control interface. Real-time communication ensures synchronized execution at each step, eliminating waiting times and errors that degrade efficiency.

We use a single control interface, allowing operators to adjust the injection molding machine, set dryer parameters, and more from a single point. There’s no longer a need to switch between five different systems. Furthermore, a unified communication language ensures that every device in the unit transmits data to the injection molding machine’s central controller. If the dryer detects that the material’s moisture content is 0.5% above the target value, it alerts the injection molding machine, which automatically adjusts the screw speed to compensate. If the robot lags, the injection molding machine pauses the next cycle rather than ejecting the part into an empty slot. Topstar’s tests show that this integrated design reduces unplanned downtime by 40% and labor inefficiency by 25%, the two main drivers of an overall 15% increase in efficiency.

Performance Upgrades, Integration is Effective

Topstar molding machines also enhance their original performance through hardware upgrades, translating coordinated steps into faster, more reliable production. Three key improvements, working synergistically with the integrated system, achieve a 15% efficiency increase: 20% more servo power, 20% higher injection speed, and 10% higher screw speed. Each improvement targets critical aspects of the injection molding process without compromising part quality.

- 20% Increase in Servo Power: Faster, Smoother Movement

We use servo motors that provide 20% more torque for clamping and injection movements. This reduces mold closing time by 0.8 seconds and ejection time by 0.5 seconds. These small savings per cycle accumulate to produce an additional 120 parts per hour within a 45-second cycle.

- 20% Increased Injection Speed: Perfect Cavity Filling, Zero Scrap

Topstar’s injection units reach speeds of up to 350 mm/s, a 20% increase, ensuring fast and uniform cavity filling, crucial for thin-walled parts. Faster injection speeds reduce “short shots” and “shrinkage marks,” thus lowering scrap rates.

- 10% Increased Screw Speed: Faster Plasticization, No Degradation

Our 40 mm diameter screw speeds at 220 rpm, a 10% increase, accelerates resin melting without overheating. Faster plasticization reduces “dwell time” by 1.2 seconds, shortening cycle time and preventing material degradation. Overall, these upgrades and integrated systems together achieved a 15% efficiency improvement.

Topstar’s molding machine demonstrates high production efficiency in real-world applications

Case 1: Automotive Interior Clips

Problem: 45-second cycle time; 8% scrap rate; 12 operators working overtime to reach a weekly output of 100,000 pieces; monthly overtime pay/late fees reaching $14,000.

Solution: Topstar TMⅡ injection molding machine.

Result: Cycle time reduced to 39 seconds (13% speed increase); scrap rate reduced to 2%; 100,000 pieces per week achieved with only eight operators.

Case Study 2: PET Beverage Bottles

Challenges: 28-second cycle time, 5% scrap rate, and high energy costs.

Solution: Topstar TMⅡ injection molding machine (10% increase in screw speed, energy-saving servo system).

Results: Cycle time reduced to 24 seconds (14% speed increase); scrap rate reduced by 1.2%

Efficiency is not just about speed; it is also about control.

For customers, low production efficiency is not an “inevitable reality,” but rather a consequence of outdated, siloed equipment that cannot keep pace with modern manufacturing. Topstar molding machines solve this problem by transforming your injection molding unit into an interconnected, high-performance system, resulting in a 15% increase in overall efficiency and measurable cost savings.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/12/12

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/12/12

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/12/12

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/12/12

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar