How to Solve Poor Plasticization in the Injection Molding Process?

2025/12/15 By le zhan

Poor plasticization in the injection molding process can lead to bubbles, uneven surfaces, or brittle edges on parts, making them unsuitable for quality inspection. This not only wastes raw materials but also consumes time and increases labor costs. The main problem lies in poor management during the pre-plasticization stage; unstable pressure or temperature can cause insufficient melting or excessive degradation of the plastic resin. Topstar’s proportional back pressure control technology effectively solves this problem, improving both product quality and efficiency.

The Root Causes of Poor Plasticization in the Injection Molding Process

Before addressing poor plasticization in the injection molding process, engineers must first diagnose its root cause. Plasticization is the process of melting a solid resin into a uniform flow state, which depends on three interrelated factors: temperature, pressure, and screw motion. Problems arise when any of these factors become unbalanced. Common causes include insufficient barrel temperature, excessive screw speed, or unstable back pressure. Material-related issues also play a role: damp resin absorbs moisture, which evaporates during molding, forming bubbles; contaminated particles can lead to uneven melting. Even minor changes, such as a 5°C drop in barrel feed zone temperature or a 10% fluctuation in back pressure, can disrupt the entire injection molding process. And 68% of plasticizing failures stem from controllable pre-plasticizing variables, not material defects or machine wear.

Proportional Back Pressure Control: Topstar’s Core Solution to Plasticizing Problems in the Injection Molding Process

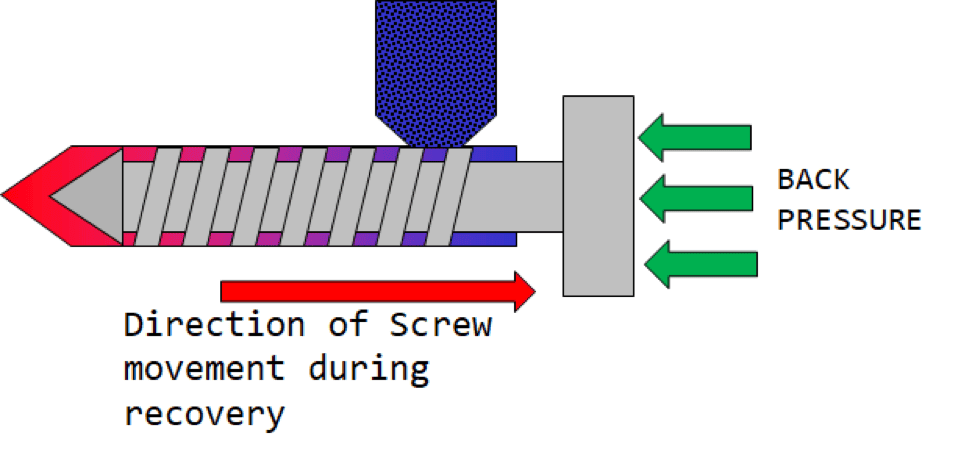

Topstar’s technological advantage lies in its pre-plasticizing stage, which directly targets the root causes of pressure-related plasticizing defects during injection molding. Traditional injection molding machines use a fixed back pressure setting—the same value for all materials and batches—a method suitable for simple processing but inadequate for complex resins such as PC or glass fiber-reinforced nylon. Topstar’s proportional back-pressure control addresses this, enabling multi-stage pressure adjustment during pre-plasticizing to adapt to the resin’s unique needs at each melting stage. Its working principle is as follows: as the screw retracts and feeds resin into the barrel, the injection molding machine automatically adjusts the back pressure according to preset parameters—using lower pressure during the initial feeding stage and higher pressure during the melting stage.

On the user interface, operators input the material type via a touchscreen, and the injection molding machine loads an optimized pressure profile, eliminating the need for repeated manual trials. Whether processing PE for packaging or rigid ABS for electronics, Topstar injection molding machines use proportional back-pressure control to adjust pressure in real time, ensuring consistent melt flow.

Optimizing Temperature Parameters for Enhanced Plasticization in Injection Molding

Combining proportional back-pressure control with precise temperature management yields optimal results and is key to resolving poor plasticization in injection molding.

We need to adhere to the temperature range recommended by the resin manufacturer: ABS requires 230–250°C to fully melt without scorching, while PE requires 180–220°C. A common mistake operators make is setting a single temperature for the entire barrel, neglecting the different roles of each zone. Topstar injection molding machines address this issue with zone-specific temperature control, calibrated to ±1°C—a precision that eliminates “cold spots” where the resin remains solid. For example, the feed zone should be cooler to prevent particle clumping, while the metering zone requires the highest temperature to ensure uniformity. Combined with proportional back pressure control, this temperature strategy effectively addresses poor plasticization.

Adjusting screw speed and rotation angle improves plasticization efficiency

Screw motion is the third key factor for effective plasticization in injection molding, and improper screw speed adjustment is a common cause of poor melt flow. Excessive screw speed generates excessive frictional heat, which can degrade sensitive resins such as PVC or TPU. Conversely, excessively slow screw speed prolongs resin residence time in the barrel, leading to uneven melting and carbonization. Topstar injection molding machines synchronize screw speed with back pressure and temperature settings. Sensors monitor melt viscosity and adjust screw speed in real time, reducing speed for high-viscosity materials like acrylic and increasing speed for low-viscosity materials like PP.

This is particularly important for batch production of blended materials. For example, if you switch from processing high-density HDPE to processing VPE and VPE blends, the injection molding machine automatically adjusts the screw speed to prevent fiber breakage and ensure uniform melt flow. By combining this with pressure and temperature control, Topstar injection molding machines transform the injection molding process into a dynamic, self-correcting system.

Pre-treatment of materials further avoids poor plasticization

Moisture is the biggest problem with injection molding materials, such as PET. This moisture turns into water vapor during melting, creating bubbles or voids in the final molded part. Contamination is another issue; dust, oil, or residual resin from the previous production process can interfere with the melting process, leading to streaks or weak points. The solution is rigorous pre-treatment. Topstar’s injection molding machines can be used with dehumidifying dryers to reduce the resin’s moisture content to below 0.02%, the threshold for bubble-free plasticization, thus providing a complete integrated injection molding process solution.

Furthermore, these machines are even equipped with a “material ready” sensor: if the dryer doesn’t process the resin long enough, the injection molding machine pauses pre-plasticization to avoid waste. Simultaneously, to prevent contamination, Topstar’s feeding system is equipped with a magnetic separator and mesh filter to remove metal fragments and impurities before the resin enters the barrel. By connecting the machine control system to the pre-treatment tools, Topstar ensures that every resin particle entering the barrel is fully prepared for plasticization.

Utilizing Proportional Back Pressure for a Stable Injection Molding Process

Poor plasticization may seem daunting, but its root lies in controllable variables: pressure, temperature, screw motion, and material pretreatment. Topstar’s proportional back pressure control is at the heart of this solution, offering flexibility for any resin while simplifying operations for the team. Combined with precise temperature zoning, variable screw speed, and integrated material pretreatment, this technology reduces scrap rates, shortens production cycles, and ensures consistent product quality.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/12/15

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/12/15

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/12/15

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/12/15

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar