How to Choose a Reliable Injection Molding Machine Manufacturer: 6 Key Criteria

2025/12/19 By le zhan

Choosing the right injection molding machine manufacturer is one of the most important decisions for plastic product buyers. The injection molding machine purchased determines part quality, uptime, energy costs, labor requirements, and ultimately impacts time-to-market. Therefore, buyers need clear and practical criteria to evaluate suppliers. You can consider them based on technology, quality control, service, spare parts, warranty, certifications, customization, and automation capabilities. Using Topstar as an example, this demonstrates how a modern, vertically integrated manufacturer can meet buyers’ needs.

Injection Molding Machine Manufacturer Technology and Product Range

When evaluating an injection molding machine manufacturer, the first question to ask is whether their product portfolio meets your technical needs. Do they produce a sufficiently diverse range of products—including toggle-type hydraulic injection molding machines, servo-hydraulic injection molding machines, and all-electric injection molding machines—to meet the needs of your current parts production and the products you plan to develop in the future?

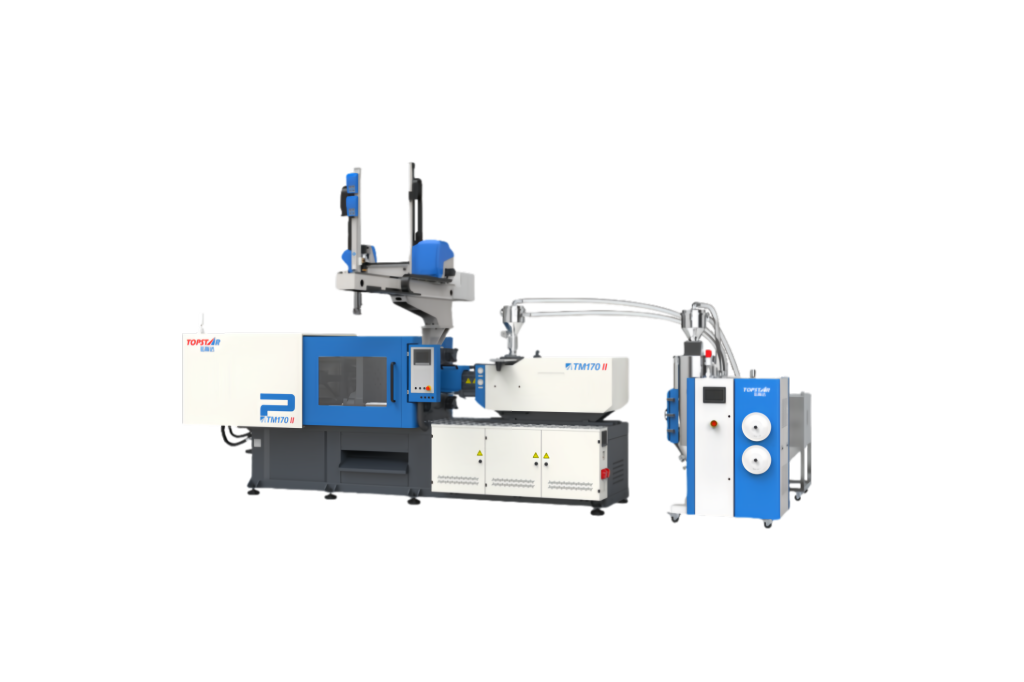

For example, Topstar’s TMII series demonstrates improved production efficiency through servo systems and integrated process control: The TMII series features stronger servo power, faster injection speeds, and overall efficiency improvements (approximately 15% efficiency increase, faster injection speeds). These product improvements are not exaggerations—they reflect engineering upgrades such as upgraded servo drives, improved injection dynamics, and tighter control loops, which are crucial for producing precision parts.

Evaluation Checklist:

- Confirm the injection molding machine series (clamping range, tonnage, screw size, all-electric options).

- Request published performance differences compared to previous models.

- Confirm whether the supplier offers integrated automation and production line-level control. Topstar’s “process integration” concept emphasizes multi-equipment linkage and one-button mold adjustment to enable faster mold changes, a growing need for buyers.

Evaluating the Injection Molding Machine Manufacturer’s Product Quality and Component Sourcing

A reliable injection molding machine manufacturer will use durable mechanical structures and high-quality sourced components to build their machines. Therefore, you can inquire whether the machine frame, toggle or clamping system, injection unit, and 510 connection hardware are designed for long life, and whether key components are sourced from reputable suppliers. For example, Topstar pairs its TMII injection molding machines with recognized controllers and servo subsystems (using KEBA controllers and PHASE/DELTA components), and emphasizes the use of linear guides for improved stability. Using established drive and controller brands reduces the risk of using uncommon and difficult-to-repair electronic components and makes on-site maintenance more predictable.

Checklist:

- Request to see the bill of materials for critical subsystems.

- Confirm the material specifications of the platens, toggle levers, and tie bars.

- Request evidence of factory pressure testing and quality assurance procedures. Topstar integrates production quality assurance and product testing procedures into its supplier commitment.

Process Control, Digitalization, and Auxiliary Systems

Modern injection molding requires more than just clamping force or peak power; process stability and consistent temperature control are key to producing repeatable parts. Therefore, we should ask injection molding machine manufacturers how they support process control, digital traceability, and auxiliary systems such as temperature regulation and material handling.

Topstar positions mold temperature control as a core competency, with mold temperature controllers featuring fast heating speeds, high stability (temperature control accuracy up to ±0.1℃), and functions to reduce water leakage and extend uptime. Precise temperature control reduces dimensional variations and scrap rates, especially for thin-walled, optical, or precision components.

Evaluation Checklist:

- Does the supplier offer integrated process control (controller + HMI + data logging) that combines the injection molding machine, clamping unit, injection robot, and mold temperature controller?

- Can the controller export SPC data and integrate with MES/ERP systems for traceability?

- Does the mold temperature controller meet the duty cycle requirements of your application and support the required accuracy (±0.1℃) when needed?

After-Sales Service, Spare Parts, and Training

One often overlooked consideration when choosing an injection molding machine manufacturer is the manufacturer’s service network. Machines are capital equipment, and the losses from unplanned downtime often far exceed the purchase price. Therefore, priority should be given to suppliers who can quickly provide spare parts, remote diagnostics, and on-site training. Topstar offers comprehensive support services, including a 12-month warranty, ample spare parts, training resources, and on-site technical support – measures that significantly reduce average repair time and help customers quickly restore machine operation. Furthermore, Topstar has multiple subsidiaries overseas to provide better localized services.

Evaluation required:

- Is the response time for spare parts and technician dispatch documented?

- Availability of consumables and wear parts.

- Training programs: on-site commissioning, maintenance training, and operator certification.

Customization, automation, and integration capabilities

Your chosen injection molding machine manufacturer must be able to modify standard machines according to your process flow: for example, adding in-line automation, automatic mold change systems, insert molding fixtures, or cleanroom configurations. Collaboration on molds, process optimization, and automation can reduce integration risks and accelerate deployment.

Topstar’s TMII platform features one-button mold adjustment and multi-technology collaboration, simplifying mold changes and enabling smoother connections between robots and peripheral equipment. This is particularly beneficial for buyers planning continuous production or multi-shift operations.

Evaluation required:

- Can the manufacturer provide a one-stop injection molding solution (including an injection molding machine, robot, and peripheral equipment) and assume overall responsibility for cycle time and quality?

- Do they provide engineering support for mold integration and process optimization?

- Does the MES and automation system integration support open interfaces (standard Ethernet/IP, OPC-UA, or fieldbus)?

Choosing a reliable manufacturer

Choosing an injection molding machine manufacturer is a strategic decision that will impact product quality, production flexibility, and cost structure for years to come. Make an informed choice based on the five criteria above – technology and product range, manufacturing quality and components, process control and auxiliary systems, after-sales service and training, and customization and automation capabilities. Topstar is a reliable injection molding machine manufacturer, combining modern servo technology and process integration with temperature control and support services to make your molding process more efficient.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/12/19

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/12/19

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/12/19

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/12/19

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar