Roller Guide vs Linear Guide Plastic Molding Machine: Injection Stability

2025/12/26 By le zhan

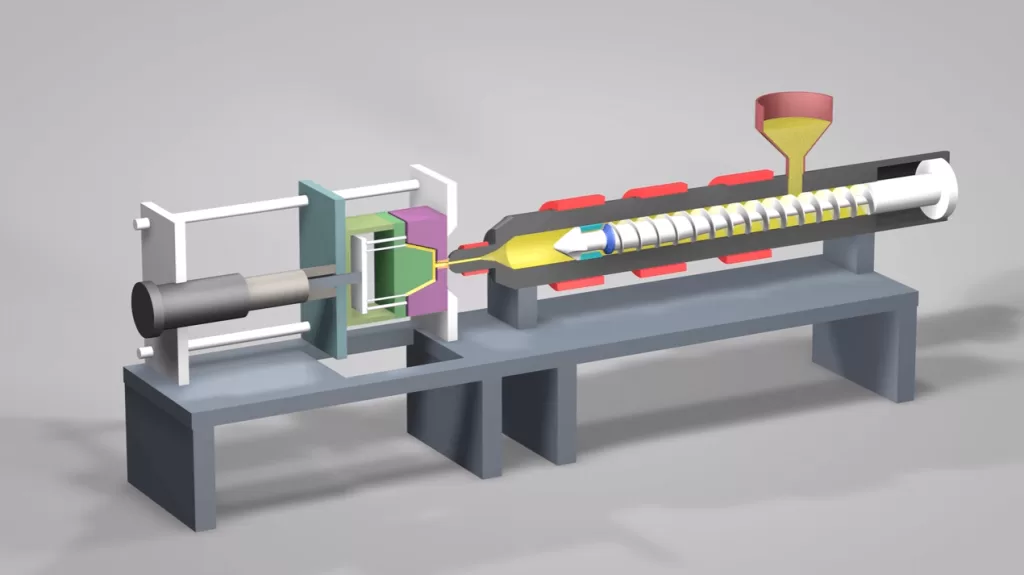

In the plastic molding process, the guide rail system of the plastic molding machine determines the mold’s movement, force distribution, and ultimately the stability of the injection molding process over thousands of cycles. Choosing between roller guides and linear guides for your plastic molding machine will impact dimensional accuracy, surface finish, repeatability, uptime, and maintenance costs.

The guide rail system on an injection molding machine provides stable motion, resists deformation, and transmits force. An improperly selected guide rail can cause mold tilting, vibration, or misalignment during the injection molding process—resulting in scrap and rework. Conversely, the right guide rail system maintains mold accuracy, reduces setup time, and delivers consistently high-quality parts.

Roller Guides vs. Linear Guides in Plastic Molding Machine

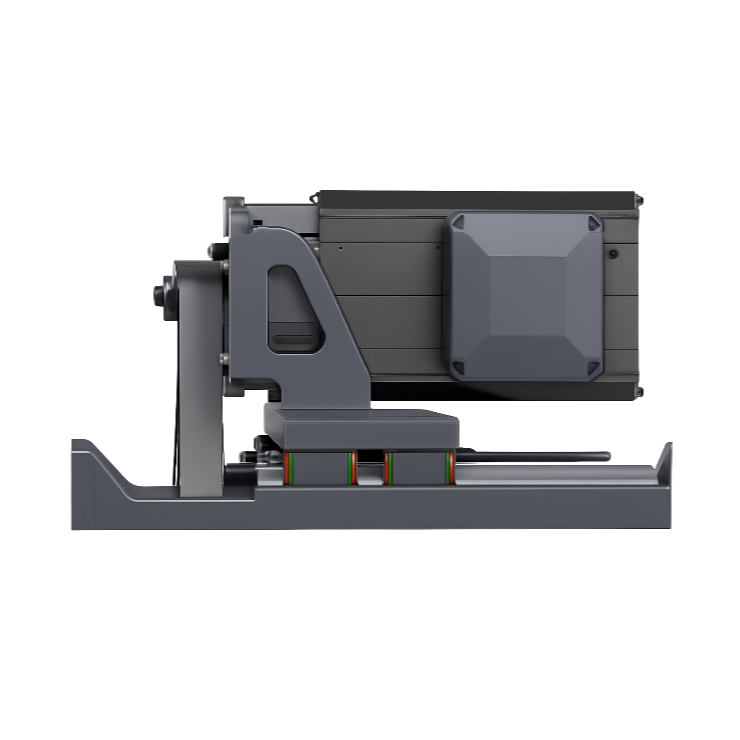

Plastic Molding Machines with Roller Guides

From a mechanical perspective, roller guides use rolling elements (precision rollers) that roll in hardened tracks on the moving platen. They can be single-roller or double-roller configurations and often incorporate preloaded cam geometry to control clearance and alignment.

Roller guides excel in high-load conditions due to their relatively large contact area and low rolling friction. They can withstand impacts and handle the heavy clamping forces typical of large plastic molding machines. Their advantages include excellent load capacity, high impact resistance, and robustness under transient loads. Many large plastic molding machines use roller guides to ensure long-term reliability.

Linear Guides

Linear guides provide a bearing block that slides along a precision rail. They offer tight preloading, low friction, and precise positioning accuracy. Linear guides excel in high-precision, high-speed applications due to their extremely low positioning error and excellent lateral dynamic stiffness. They are often used in all-electric or hybrid injection molding machines where speed and precision are critical. The advantages of plastic molding machines equipped with linear guides include high positioning accuracy, low friction, repeatable motion, and a compact structure.

How Guide Rail Selection Affects Plastic Molding Machine Stability and Part Quality?

Injection molding stability refers to a machine’s ability to maintain consistent flow, pressure, and cavity filling across cycles. The guide rail system influences this stability through alignment, torsional rigidity, and dynamic response. During injection and holding pressure, cavity pressure exerts lateral forces on the mold halves. If the platen tilts slightly due to the flexibility of the guide rails, flashing, uneven wall thickness, or weld lines may occur. Well-preloaded linear guides keep the platen’s travel parallel with tight tolerances, minimizing tilting. Roller guides can also maintain parallelism if properly designed, but require careful preloading and maintenance to avoid wear-induced clearance.

Rigid guide systems can withstand torque during high-speed injection and rapid deceleration. Linear guides, especially those arranged in pairs or using crossed roller linear bearings, provide high lateral stiffness, resulting in minimal deflection. Roller guides with larger rolling contact areas can withstand higher compressive loads but may exhibit greater microdeformation under lateral shear forces, especially if the rollers wear unevenly. Lower stiffness can lead to periodic dimensional drift, flow imbalance problems, and inconsistent gate sealing. For thin-walled or optical parts requiring micron-level stability, linear guides are generally preferred.

Lifecycle, Wear, Maintenance, and Total Cost of Ownership

Production realities demand more than just initial performance. Guide systems age, and their maintenance costs can significantly impact uptime and lifecycle costs.

Linear Guides: Wear typically manifests as increased friction in the drive system, stick-slip phenomena, or increased torque. Contamination and insufficient lubrication are common causes.

Diagnostic methods: Monitor for increased drive motor current, record changes in positional repeatability over time, and visually inspect the guide surfaces for scratches. Typical replacement cycles vary depending on the environment and maintenance, but proactive lubrication can significantly extend service life.

Roller Guides: Wear manifests as increased runout, flat spots on the rollers, or guide wear, ultimately leading to backlash and reduced parallelism.

Diagnostic methods: Check roller preload, listen for unusual noises, and measure platen wobble. Roller components may be heavier and more expensive to replace, but their robust nature often means a longer service life in harsh environments. Maintenance Measures to Maintain Injection Stability

Lubrication with the recommended grease/lubricant film thickness, as per the schedule, prevents micro-wear. For high-volume production plants, use an automated lubrication system. Environmental control is also necessary, including filtering ambient air, controlling plastic dust, and installing protective devices on the tracks. Extend the service life of linear guides, wipers, and seals. Additionally, we can use PLC or IoT sensors to track drive current, vibration, or position drift and trigger maintenance before quality defects occur.

When to Use Roller Guides and When to Use Linear Guides

Use roller guides in the following situations:

You are working on heavy-duty molds or large platen projects where compressive load and impact resistance are primary considerations. If your production environment has a high risk of contamination, well-sealed roller guides generally tolerate contaminants better. Also, for medium-to-low-speed injection and large injection volumes (thick-walled structural parts, automotive panels), you need a robust, durable, and fault-tolerant injection system.

Use linear guides in the following situations:

Your parts require strict dimensional control, such as thin-walled packaging, optical components, medical housings, or precision inserts, and require high-speed cyclic operation, short filling window times, and extremely low requirements for positional errors.

Topstar’s plastic molding machines feature a linear guide design and auxiliary roller bearings in high-load areas, combining various advantages. When designing plastic molding machines for customers producing thin-walled consumer goods, we typically specify high-load capacity linear guides with redundant carriages and integrated lubrication systems.

Selection and Recommendations

Choosing between roller guides and linear guides for your plastic molding machine is a strategic engineering decision, not just an option on a procurement list. Roller guides are robust and have high load capacity, suitable for large molds and harsh environments. In contrast, linear guides offer high positioning accuracy and low friction, making them more ideal for thin-walled, high-speed, and high-precision production. Therefore, you need to choose the appropriate guide type based on part requirements. For parts with strict tolerance requirements and high demands on optical surfaces, prioritize plastic molding machines with linear guides; for parts with high load or impact resistance requirements, choose roller guides.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/12/26

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/12/26

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/12/26

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/12/26

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar