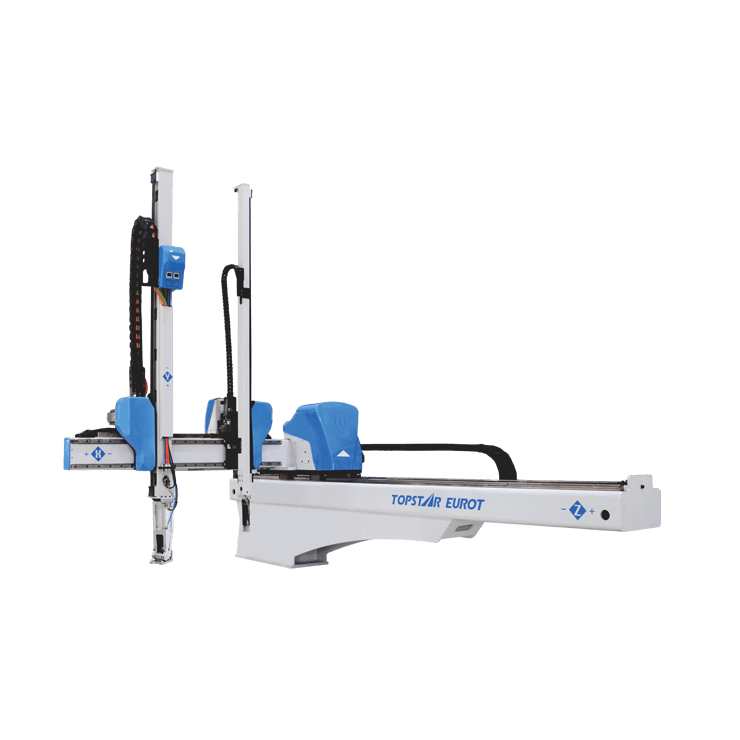

Topstar EU Injection Robot vs Traditional Robots: Energy Savings & Speed Differences

2026/01/04 By le zhan

Shortening each injection molding cycle by a fraction of a second can reduce robot energy consumption by nearly half, while maintaining the same production output. This is the practical benefit sought in modern injection molding production. Therefore, choosing the right injection robot is not just about specifying parameters; it is a strategic decision that affects cycle time, energy consumption, maintenance costs, and total cost of ownership (TCO). Topstar’s EU servo injection molding robots are made of lightweight, high-strength A6061 material to improve overall operational performance. Maximum speed is increased by 10%, and acceleration and deceleration times are reduced by 20%. The DC bus technology used also saves 10% in energy consumption, reducing electricity costs by 10%. Compared to many traditional designs, this allows for faster movement speeds and lower energy consumption.

Mechanical Design of Injection Robot: The Importance of A6061 Material

The core of mechanical performance lies in the design of the injection molding robot’s arm. The Topstar EU injection robot‘s arm is made of A6061 aluminum alloy, reducing structural weight while maintaining rigidity. A6061 is an aluminum alloy with an excellent strength-to-weight ratio, good fatigue resistance, and high machinability. By using A6061 for the robotic arm’s main components, Topstar reduces the arm’s rotational inertia. This reduced inertia brings two important advantages to the injection molding robot:

Faster movement speed: Lower inertia means the servo motor requires less torque to accelerate and decelerate the same load. Therefore, compared to steel robotic arms with equivalent load capacity but greater weight, the Topstar EU robot’s maximum speed increases by approximately 10%. For the short-distance pick-and-place movements common in injection molding cycles, this 10% improvement can significantly shorten cycle times.

Shorter acceleration and deceleration times: A lighter robotic arm is easier to start and stop. Topstar’s data shows that acceleration and deceleration times are reduced by approximately 20%, resulting in more precise motion control and faster, safer repositioning. Shorter acceleration and deceleration times increase throughput and smooth motion, reducing part oscillation and improving placement accuracy. In contrast, many traditional injection molding robot arms use heavier steel or cast iron components to achieve maximum rigidity, but at the cost of higher inertia.

DC Bus Technology in the Injection Robot

The energy efficiency of injection robots increasingly depends on how effectively they capture and reuse energy during deceleration and idle periods. Topstar’s EU injection robots utilize DC bus energy regeneration and local energy management strategies to capture braking energy and reduce overall power consumption.

When the injection molding robot decelerates, its servo motors act as generators, converting kinetic energy into electrical energy. Unlike many traditional systems that dissipate this energy as heat through braking resistors, the DC bus energy recovery system recovers it and returns it to the DC bus. The total DC bus can power other axes or nearby systems, or local capacitors or batteries can store it for subsequent acceleration events. This reduces the facility’s net energy consumption from the power grid.

In a typical injection molding cycle, DC bus regeneration technology can save approximately 10% of energy. The specific energy savings depend on the motion profile—systems with frequent starts and stops and large decelerations benefit the most. Energy reuse reduces peak power demand, thereby lowering demand charges and enabling smaller upstream power infrastructure. Traditional injection robots lack DC bus energy regeneration capabilities and typically dissipate deceleration energy as heat, thus missing the opportunity for energy recovery. In high-volume injection molding production lines, where injection molding robots cycle thousands of times a day, energy losses from braking add up to a significant expense.

Servo Drive Automatic Shutdown and Reduced Idle Power Consumption

Another area of energy waste is idle and standby power consumption. Traditional injection molding robots typically keep servo drives and control electronics in a ready state, continuously consuming power even when they are in a cycle waiting state. Topstar’s EU robots address this issue with intelligent servo drive automatic shutdown functionality.

When the robot enters a confirmed standby window (e.g., extended cycle pauses, machine downtime), the controller safely shuts down the servo amplifiers while maintaining the robot’s position using mechanical brakes or low-power holding circuits. The servo drives can be quickly re-initialized as needed to resume motion. Modern design minimizes restart delays, thus avoiding process interruptions.

Our test studies revealed that the automatic shutdown of the servo system further reduced power costs by approximately 10%. This energy-saving effect complements DC bus energy regeneration; energy regeneration saves energy during motion, while automatic shutdown reduces energy consumption during idle states. In contrast, traditional robots without this feature continuously consume idle power and generate heat.

Cycle Time and Actual Production Efficiency Improvements

While energy saving is important, manufacturers also value production efficiency. Shorter cycle times directly increase output and spread capital costs over more parts.

Assume a traditional injection robot contributes 0.6 seconds to an injection cycle (pick, place, retract). The Topstar EU injection molding robot achieves a 10% increase in maximum speed and a 20% reduction in acceleration/deceleration. These two improvements together narrow the robot’s motion window. Conservatively, depending on the trajectory’s complexity, this can reduce the robot’s operating time per cycle by 15% to 20%.

This practical result translates into higher hourly output, and even small reductions per cycle accumulate to significant effects over thousands of cycles. For example, on a medium-volume production line running 100,000 cycles per week, a 15% reduction in robot operating time can be equivalent to an extra shift’s capacity without adding a second production line. Simultaneously, faster injection molding robots reduce the injection molding machine’s idle time, making it easier to optimize clamping/opening timing and reduce press dwell time. This translates into less scrap and less manual intervention. Additionally, shorter cycle times, combined with DC bus regeneration and servo shutdown, reduce total energy consumption per part.

Reliability, Maintenance, and Cost

Topstar’s lightweight robotic arms and efficient drive strategies affect maintenance and reliability metrics, which directly impact the total cost of ownership. In terms of maintenance and reliability, they feature lower dynamic stress, reduced inertia, and smoother motion curves, thus reducing stress on mechanical joints and bearings, leading to lower failure rates and longer preventive maintenance cycles. Simultaneously, the system reduces heat load; energy recovery and idle shutdown reduce the heat generated in the drive cabinet, thereby lowering cooling requirements and extending component lifespan. From a cost perspective, DC bus energy regeneration and standby shutdowns significantly reduce energy consumption. Combined with shorter cycle times, the energy savings per part are substantial.

Overall, the Topstar EU injection robot system combines mechanical design, servo control, and energy architecture to deliver a better total cost of ownership than many traditional designs, especially in high-cycle production.

Bringing you faster speeds and better energy efficiency

Choosing the right injection robot means balancing speed, energy consumption, reliability, and integration. Topstar’s EU series injection molding robots, featuring a lightweight A6061 aluminum alloy robotic arm, DC bus energy regeneration, and servo automatic shutdown, offer significant advantages over traditional injection molding robots. These features enable approximately 10% higher maximum speed, 20% shorter acceleration/deceleration times, and significant energy savings. These improvements work together to achieve faster cycle times, lower energy consumption per part, and lower operating costs.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/01/04

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/01/04

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/01/04

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/01/04

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar