Controllable temperature range: Topstar mold temperature controller meet diverse needs

2026/01/19 By le zhan

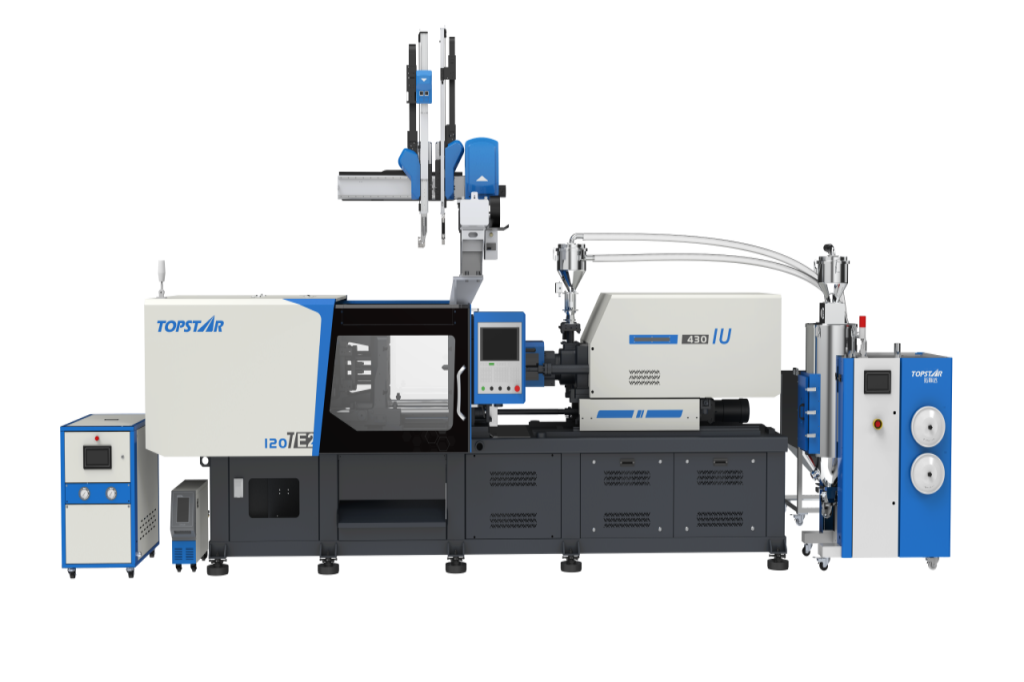

When stable and responsive, the part can be molded in a single cycle. Once temperature deviations occur, cycle time, part dimensions, and product yield are all affected. Topstar’s mold temperature controller combines a dedicated 7-inch touchscreen, an optimized PID algorithm that improves control efficiency by approximately 10%, and a fast-response solid-state relay with a switching speed of only 0.1 seconds, providing stable mold temperature for various injection molding applications.

Why is a controllable temperature range important in injection molding?

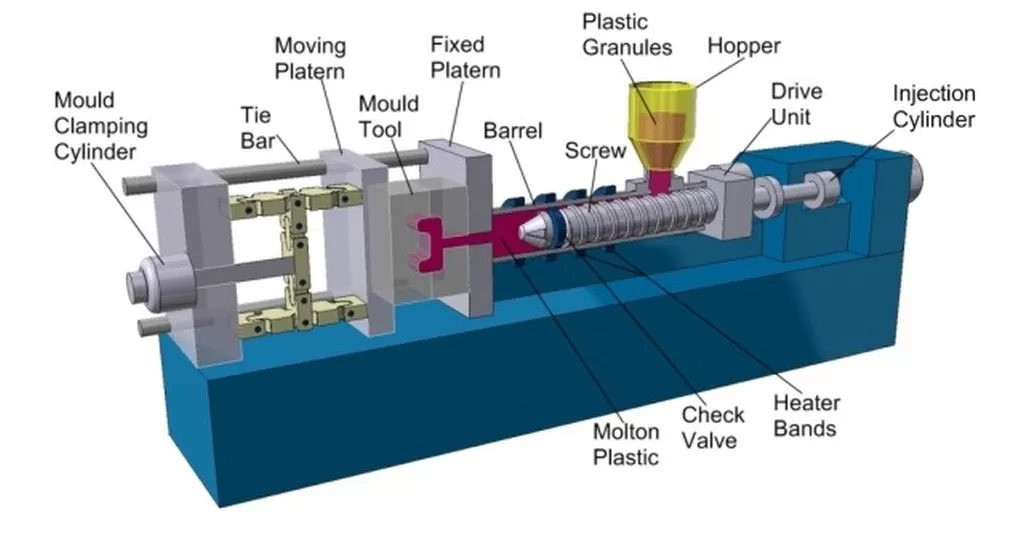

Mold temperature directly affects melt flow, cooling behavior, crystallinity, and surface finish. For injection molding machines, the appropriate mold temperature range varies depending on the polymer and process:

Low-temperature processes: Cooling in the 20–80°C range is usually sufficient to maintain shape and fast cycle times.

Standard thermoplastics (ABS, PP, PE): Molds typically operate at temperatures of 40–90°C, depending on wall thickness and surface finish targets.

High-performance engineering plastics (PC, PBT, PA, PET): Higher mold temperatures are required—sometimes up to 80–140°C—to minimize stress, improve surface gloss, and accelerate crystallization.

Ultra-high-temperature materials (PEEK, PPS, high-crystallinity LCP): Mould circuits capable of withstanding 200°C or higher may be required; oil-based mold temperature controllers typically offer temperature ranges up to 320°C.

A mold temperature controller with a wide, stable, and rapidly controllable range allows manufacturers to handle multiple polymers and mold types without changing equipment. This flexibility reduces capital costs and shortens mold changeover times. Furthermore, the closer the mold temperature is to the target temperature and the smaller the overshoot, the more consistent the part characteristics obtained on the injection molding machine. In other words, the wider the controllable range, the greater the process flexibility.

Topstar Mold Temperature Controller Touchscreen and PID Control Advantages

Topstar equips its mold temperature controllers with a dedicated 7-inch touchscreen controller designed for ease of use and precise setpoint control. The touchscreen provides operators with intuitive access to setpoints, heating curves, alarm thresholds, and historical data—crucial when running multiple moulds or balancing across various zones.

In addition to the ergonomic interface, Topstar uses an optimised PID temperature-control algorithm, resulting in approximately 10% greater temperature control efficiency than traditional methods.

The importance of PID:

Proportional control (P) reduces most of the error between the set temperature and the actual temperature.

Integral (I) corrects residual steady-state errors (offsets) that develop over time.

Derivative (D) dampens rapid changes and helps prevent overshoot.

Topstar’s optimized algorithm adapts to the thermal dynamics of specific molds/loads. This reduces overshoot during heating, shortens stabilization time, and minimizes temperature cycling that stresses the injection molding process. For example, molds with high thermal mass typically require a conservative P value and a higher I value; Topstar’s controller automatically adjusts to these dynamics, reducing the need for manual readjustment.

Practical benefits of the PID control algorithm include:

Improved temperature uniformity in the cavity and cycle, resulting in better dimensional consistency.

Reduced break-in time for new molds and faster injection molding machine qualification.

Reduced scrap and improved surface consistency in critical applications such as medical or optical parts.

Therefore, combined with the straightforward touchscreen user interface, the PID control functionality makes it easier for production line operators and engineers to set, monitor, and maintain ideal mold temperatures.

Fast-Responding Solid-State Relays and Their Impact on Yield

Topstar mould temperature controllers use solid-state relays with a response time of only 0.1 seconds, enabling fast, smooth switching of heater loads. Unlike mechanical contactors, solid-state relays switch electronically, eliminating arcing and contact wear while significantly reducing electromagnetic noise.

In the injection molding field, these advantages translate to:

Higher effective resolution: Solid-state relays pulse the heating power in acceptable increments, supporting precise temperature control, especially for small-thermal-mass molds.

Reduced mechanical maintenance: No contact erosion means lower failure rates and reduced scheduled maintenance. Faster Corrective Actions: SSRs react within 0.1 seconds—crucial when injection molding cycles or localized exothermic events require rapid temperature correction.

Reduced Thermal Fluctuations: Finer control reduces the amplitude of temperature fluctuations, improving part quality and repeatability.

Mold Temperature Controller Integration and Digital Upgrade with Injection Molding Machines

In modern injection molding facilities, equipment integration is crucial. Topstar’s mold temperature controllers are designed for seamless integration with injection molding machines and digital systems:

Control Interoperability: The controller supports Modbus, Ethernet/IP, and other industrial protocols. This allows the controller to exchange setpoints, alarm information, and performance metrics in real time with the injection molding machine PLC and factory MES systems.

Digital Upgrade: A 7-inch touchscreen supports recipe storage and quick setpoint recall to reduce changeover time between parts or molds, especially useful when the injection molding machine runs multiple SKUs.

Data Logging and Traceability: The mold temperature controller can log temperature profiles and alarm information, aiding root cause analysis in the event of quality incidents. This data also supports compliance requirements in regulated industries.

By interconnecting mold temperature control with injection molding machine control, Topstar helps factories achieve more innovative production: synchronized startup sequences, automatic preheating curves matched to machine cycles, and coordinated alarm handling, resulting in reduced mean time to repair. Ultimately, this digital coordination helps improve yield and product reliability.

Enhanced Safety and Energy Efficiency

Topstar incorporates safety and efficiency into its hardware and processes, as high-temperature molding circuits in injection molding present safety and energy challenges. Key features include:

Safety Features:

Independent Over-Temperature Protection: Hardware high-temperature limiters and thermal fuses cut off power to the heaters if the central control fails.

Isolated Circuits and Safety Interlocks: Protective doors, flow switches, and door interlock logic prevent the injection molding machine from operating if the thermal circuit is compromised.

Leak Detection and Alarms: Level and pressure sensors notify operators before leaks or pump failures affect components or equipment.

Energy Efficiency:

Improved PID Control Efficiency: Control efficiency is improved by 10%, reducing heater cycling and energy waste. Stable control of setpoints minimizes energy loss due to overshoot. Adaptive Heating: Controllable heating curves reduce peak power consumption while still ensuring timely mold readiness.

Thermal Insulation and Minimized Dead Volume: Well-insulated pipelines and minimized manifold volume reduce standby heat loss and improve overall system performance.

Controllable Temperature Range to Meet Diverse Needs

Topstar’s mould temperature controllers combine a 7-inch touchscreen, improved PID control, and 0.1-second SSR switching to meet the temperature requirements of various injection-moulded products. They broaden the controllable temperature range, enabling faster stabilization and more stable operation, supporting digital transformation goals, and ensuring high yields across various polymers and complex molds. With proper selection and integration, these controllers can reduce waste, improve production efficiency, and support a broader range of manufacturing applications on modern injection molding machines.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/01/19

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/01/19

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/01/19

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/01/19

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- injection moulding dryer

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar