Why can Topstar dehumidifying dryer provide a stable low dew point for injection molding?

2026/02/17 By le zhan

Even trace amounts of moisture in hygroscopic resins can lead to hydrolysis, bubbles, and short shots, thus reducing the first-pass yield. Dehumidifying dryer address this problem by providing reliably low dew point drying air, ensuring that the polymer entering the injection molding machine is stable and its performance is predictable. Topstar’s dehumidifying drying solutions stand apart from others by utilizing high-quality honeycomb rotors to deliver stable, low dew point drying air. Dehumidification, drying, and conveying functions are integrated into a compact unit, ensuring efficient material handling. A dual-cooler dehumidification system reduces return air temperature and stabilizes the dew point.

Why is a stable low dew point from a dehumidifying dryer crucial for molding quality?

The fundamental function of a dehumidifying dryer is to remove water vapor, bringing the dew point of the drying air to a target dew point suitable for the type of resin being processed. Even minor fluctuations in dew point can lead to changes in resin moisture content, which in turn alter melt viscosity, flow front progression, and packing behavior during injection molding. For hygroscopic resins such as nylon, PET, and specific engineering plastics, maintaining a dew point well below 0°C is critical to prevent subtle but far-reaching performance degradation.

Topstar’s dehumidifying dryers achieve stable dew points through two complementary strategies: high-performance honeycomb rotors and precise thermal/hydraulic control. The honeycomb rotor provides a high surface area within a small footprint, enabling efficient moisture capture and rapid desorption during the regeneration process. Importantly, dew point stability is not just about achieving a low value instantaneously, but about maintaining that setpoint under varying environmental conditions and production rates. By combining a large-capacity rotor with intelligent regeneration timing and controlled airflow, the system consistently maintains the drying air delivered to the dryer outlet and the injection molding machine within tight tolerances, minimizing process variations.

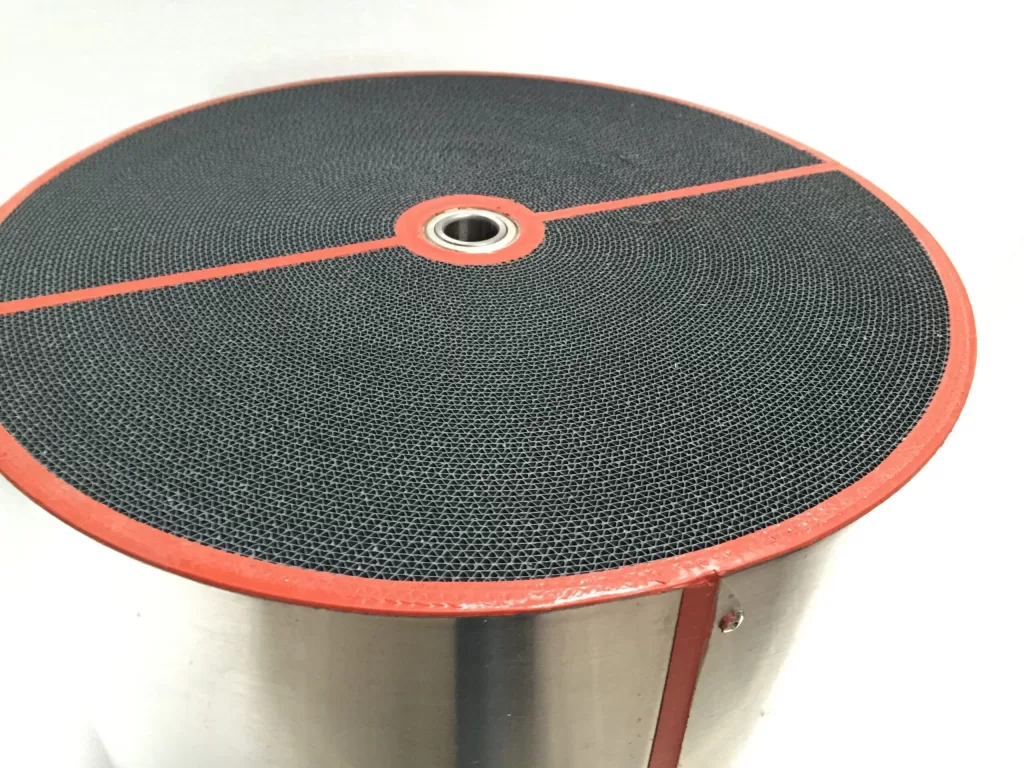

Honeycomb Rotors: The Core of Stable Low Dew Point Performance

Honeycomb rotors are at the heart of Topstar’s reliable dehumidification performance. These rotors utilize engineered adsorbent media, forming thin-walled hexagonal channels that significantly increase the contact area between the process air and the desiccant while minimizing pressure drop. The result is efficient moisture absorption during the adsorption phase and predictable, complete moisture release during the rotor regeneration phase. Due to the continuous rotation of the rotor, different sections simultaneously perform adsorption and regeneration, resulting in a stable output of dry air.

Two characteristics of the honeycomb rotor are crucial for maintaining a low dew point. First, engineers optimize the selection and packing density of the desiccant medium to balance adsorption capacity and pressure drop, ensuring deep drying even at high throughputs. Second, the mechanical tolerances and seals between the rotor sectors minimize bypass and leakage. Combined with precise rotor speed control, these mechanical and material choices ensure repeatable dew point performance in every cycle.

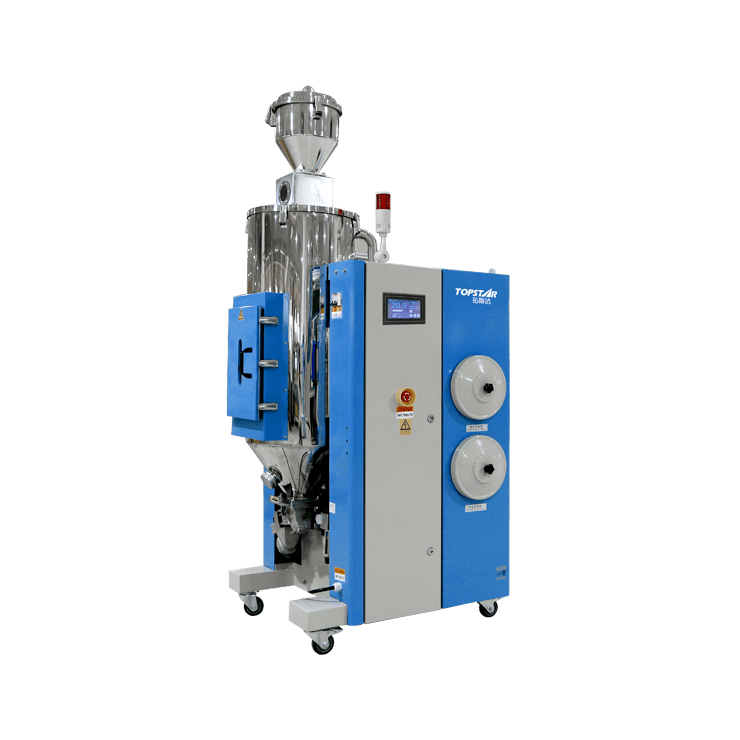

Three-in-One Compact Dehumidifying Dryer: Integrated Design, High Efficiency, Small Footprint

Modern injection molding production lines require compact, integrated solutions that save space and simplify facility connections. Topstar’s three-in-one compact dehumidifying dryer integrates dehumidification, drying hopper, and conveying functions into a single modular unit. This all-in-one design reduces interfaces that could introduce moisture or contaminants and shortens the conveying loop length between the dryer and the injection molding machine, minimizing the amount of air that needs to be kept dry and reducing the risk of dew point drift during conveying.

The integrated design brings higher operational efficiency to injection molding production. By coordinating the dryer, hopper, and conveying system with a unified control algorithm, the system can synchronize regeneration cycles, conveying pulses, and material metering, preventing regeneration heat from inadvertently heating the drying air or the material in the hopper. For manufacturers with limited space, this three-in-one compact dehumidifying dryer provides stable, low dew point performance without the need for complex components and control loops.

Lowering Return Air Temperature for Improved Stability

To further stabilize the dew point, Topstar employs a dual-cooler dehumidification system that separates and processes the process airflow and regeneration airflow, lowering the return air temperature and improving adsorption efficiency. At the same absolute humidity, lower temperature return air carries less moisture; when the rotor receives lower temperature return air, the entire system achieves a lower and more stable dew point at the dryer outlet.

The dual-cooler system also reduces thermal cycling stress on the rotor and its associated components. By regulating regeneration temperature and preventing hot spots, the system ensures a predictable desorption process, avoiding desiccant overheating or premature aging. In fact, the two-stage or dual-cooler configuration reduces dew point spikes during ambient temperature increases or production peaks. These factors contribute to increased uptime and throughput for injection molding lines.

Sealed Conveying Loop and Shut-off Valve: Preventing Moisture Re-entry

Even the best dehumidifying dryer can be compromised by poor conveying design. Air leaks, open hopper openings, or excessively long unprotected piping can allow ambient moisture to infiltrate between the dryer outlet and the injection molding machine throat. Topstar mitigates this risk with a sealed conveying loop and positive shut-off valve. The sealed loop prevents ambient air ingress, and the shut-off valve isolates the conveying line during shutdowns or material changes, preventing residual material or humid air from re-entering the dry material stream.

The sealed loop maintains a low dew point even during downtime. The shut-off valve serves both safety and process control functions: it prevents backflow, limits cross-contamination during multi-material operations, and enables rapid purging and recovery with minimal dew point recovery time. For manufacturers running multiple resins on the same line or those with stringent humidity control requirements for engineering plastics, this combination of sealing and positive isolation maintains the performance of the dehumidifying dryer.

Stable Low Dew Point for Injection Molding

Maintaining a stable low dew point is crucial for maintaining material integrity and process consistency. Topstar’s dehumidifying dryers address the causes and consequences of moisture variations with a high-performance honeycomb rotor, an integrated 3-in-1 compact dehumidifying dryer design, a dual-cooler dehumidification system, and a fully sealed conveying loop. These design features work together to provide reliable dry air, prevent moisture re-entry, and simplify daily operation. As a result, manufacturers benefit from a more stable low dew point, lower defect rates, and higher energy efficiency.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/02/17

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/02/17

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/02/17

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/02/17

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar