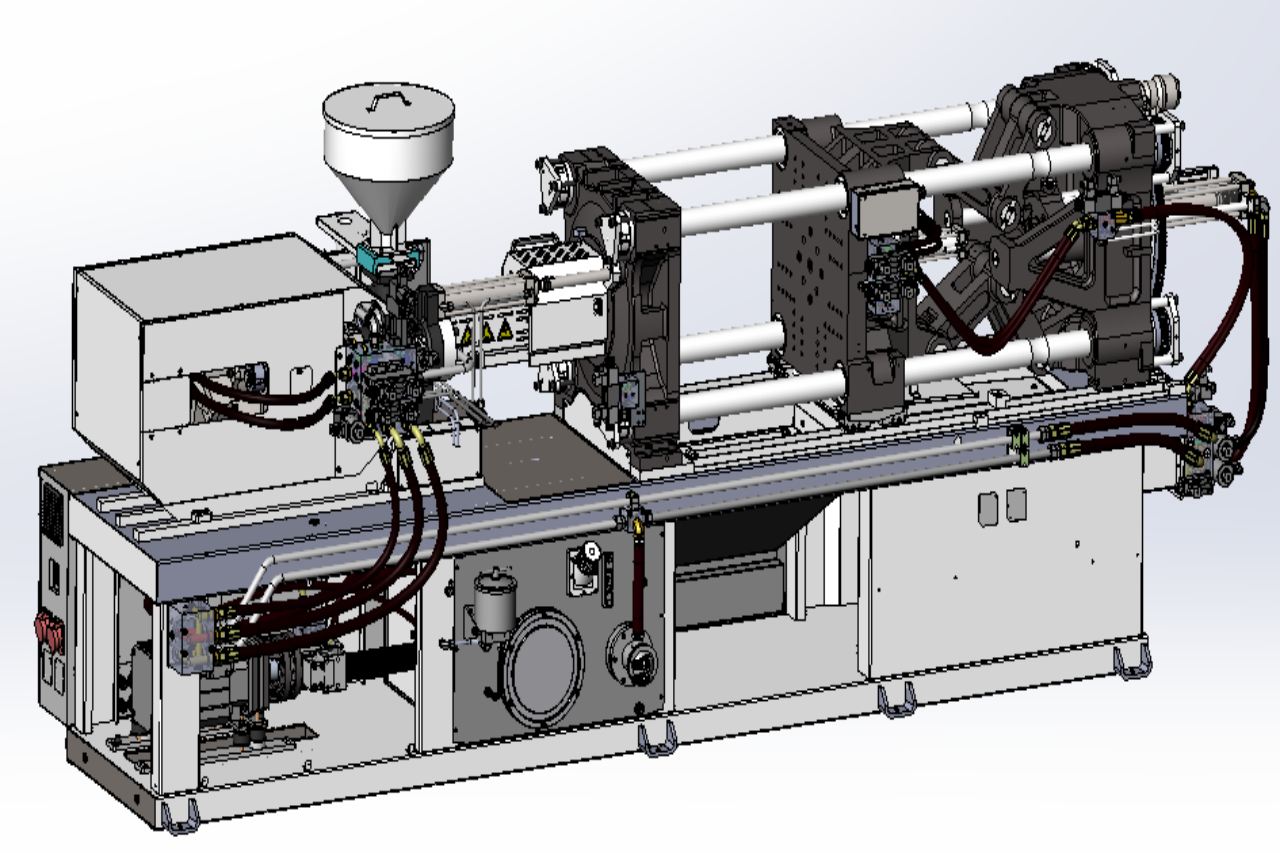

Analysis of the root cause of the hydraulic pressure drop of the injection molding machine

2025/06/04 By Topstar

When hydraulic pressure drops in an injection molding machine, it can result in incomplete mold filling and inconsistent part dimensions. Therefore, our operators need to understand the root cause of the hydraulic pressure drop and take corresponding measures. Then, we will analyze the root cause from the perspective of the injection molding machine manufacturer. First, we will examine how hydraulic oil quality and contamination can lead to pressure drop. Next, we will discuss the wear and internal leakage of hydraulic pumps, which can impact the maximum pressure output. Next, we will assess whether valve failure is a significant factor in the unstable pressure curve. After that, we will analyze and investigate the causes, including cylinder seal wear and pipeline leakage.

Hydraulic oil quality and contamination of the injection molding machine

First, one of the most common reasons for hydraulic pressure drop in injection molding machines is the poor quality of the hydraulic oil. When your injection molding machine has been in use for an extended period, the hydraulic oil will degrade due to oxidation, thermal decomposition, and contamination, resulting in an increase in viscosity and a reduction in flow. When the viscosity of hydraulic oil exceeds the manufacturer’s specifications, pump efficiency decreases, and the pressure cannot reach the required set point. Additionally, particulate contaminants such as metal chips, dust, and moisture in the workshop can clog the tiny passages of servo valves and proportional regulators, resulting in limited flow and pressure loss under load.

To address this, we can perform an oil analysis every two weeks, check ISO cleanliness codes and monitor water content to less than 200 ppm. Additionally, maintaining an oil temperature between 40°C and 60°C optimizes viscosity. At the same time, manufacturers should equip hydraulic oil tanks with heat exchangers or coolers to dissipate the heat generated during long production runs. If the analysis reveals elevated water or acidity levels, technicians must replace the oil entirely and flush the system.

Wear and internal leakage of hydraulic pumps in the injection molding machine

In injection molding machines, the pump is their “heart,” converting mechanical energy into hydraulic pressure. However, internal wear affects gear pumps, vane pumps, and piston pumps alike, and as operators use them over time, their volumetric efficiency and mechanical efficiency gradually decrease. As the pump wears, the gap between the piston and the cylinder or between the gear and the housing will expand, causing the fluid to bypass under pressure. This internal leakage prevents the pump from building full pressure, resulting in a pressure drop that can make the set clamping pressure unattainable or cause the injection speed to be unstable under high back pressure.

To diagnose pump-related pressure problems in an injection molding machine, measure the pump outlet pressure with a calibrated meter and compare it to the expected rated output. If the pump cannot reach this set point, there is most likely an internal leak. Disassembling the pump to inspect the vanes, pistons, and ports for wear can also confirm the diagnosis. Volumetric efficiency can be restored by replacing or re-machining worn parts. Proactively monitoring pump health and addressing wear issues can avoid incidents of sudden drops in hydraulic pressure.

Valve Failures and Control Issues

In an injection molding machine, hydraulic valves regulate the flow of fluid to the clamping unit, injection cylinder, and servo actuator. Valve failures are also a common cause of hydraulic drops. For example, a worn spool in a directional valve may allow an internal bypass, preventing the machine from reaching the desired clamping force. Similarly, if the spring tension of a pressure relief valve weakens, it may rupture prematurely, causing a drop in pressure throughout the system. Proportional valves rely on precise solenoid currents, and if wear damages the internal orifice or a short occurs in the coil windings, the valve may leak, which causes inconsistent pressure regulation and erratic injection speeds.

To troubleshoot valve-related pressure problems on hydraulic injection molding machines, first, confirm that the electrical signal from the proportional valve is consistent with the specified value under nominal conditions. Next, use a digital multimeter to measure the actual coil resistance. If the reading deviates from the manufacturer’s specified range, it indicates that the coil has sustained damage. You can also disassemble the valve body and visually inspect the sealing surface to check for scratches or contamination on the valve core. In this way, you can gradually troubleshoot valve failures and maintain regular operation.

Cylinder seal wear, pipeline leaks and system lags.

Worn cylinder seals or leaks at pipeline joints also cause a drop in hydraulic pressure in injection molding machines. During repeated pressing cycles, dynamic seals on injection cylinders and clamping cylinders wear due to friction. Even minor leaks can cause the system to be unable to maintain maximum pressure under load, resulting in slow clamping or inconsistent holding force during injection. Similarly, external pipeline leaks at joints, hoses, or quick connectors can cause fluid to escape before it reaches the actuator, thereby reducing the available pressure.

We need to combine visual inspection and pressure decay testing. First, shut down the injection molding machine and visually inspect the hoses and joints for signs of leaks. Next, use a hand pump to pressurize each circuit while isolating the valve; monitor the pressure decay every 60 seconds. A significant pressure drop (more than 5%) indicates a leak. For cylinders, dye penetrant or ultrasonic leak detectors can be used to pinpoint internal seal damage. Crimped stainless steel hoses, with appropriate bend radii and torque fittings, can minimize external leakage.

Analyze the root cause for targeted optimization.

The hydraulic pressure drop in an injection molding machine can be caused by multiple interrelated factors, including hydraulic oil quality degradation, pump wear, valve failure, seal leakage, and other issues. By analyzing each component of the injection molding machine, the root cause of pressure loss can be identified, and targeted corrective measures can be implemented. Using real-time monitoring, precise component inspection, and data-logged diagnostic curves, hydraulic pressure drop problems can be effectively addressed to improve consistency in production cycle time and extend equipment uptime.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/06/04

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/06/04

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/06/04

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/06/04

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar