Can Topstar Plastic Molding Machine Handle High-Temperature Plastics for Injection Molding?

2026/01/16 By le zhan

Processing high-temperature plastics requires exceptional care, demanding precise heating, controlled shearing, and reliable thermal management; otherwise, both material performance and production efficiency will be compromised. As a professional injection molding machine manufacturer, we believe that a plastic molding machine must combine the correct screw metallurgy, precise temperature control, robust mechanical design, and safe and reliable electrical isolation to reliably process materials such as PC, LCP, PEEK, and high-viscosity PET. Therefore, we will explain in detail how Topstar’s plastic molding machines meet the molding requirements of these high-temperature materials.

Core Design Features of Topstar Plastic Molding Machine for High-Temperature Processing

High-temperature injection molding requires more than just higher controller set points. It requires a plastic molding machine specifically designed to withstand sustained thermal loads and maintain stable plasticizing performance. Topstar meets these critical requirements through the following key design features:

Standard Plating Screw: With melt temperature control. The chrome plating process improves wear resistance and reduces friction between the metal and resin, minimizing abrasion and particle generation under high-temperature melts. More importantly, integrated melt temperature control ensures that the melt temperature exiting the screw remains within a narrow range, stabilizing viscosity and guaranteeing repeatability with each shot when processing heat-sensitive polymers.

Robust Barrel and Feed Throat Design: High-temperature resins often require longer residence times and specific shear characteristics. Topstar precision-machines and hardens its barrels to ensure uniform heat transfer and prevent localized overheating or resin stagnation. The feed throat design enables stable feeding and prevents bridging in glass fiber reinforced or high-viscosity compounds.

The selection of these precision components allows the injection molding machine to produce a consistently high-quality melt, even under repeated high-temperature cycles.

Topstar Plastic Molding Machine Equipped with PVD Alloy Screw Heads and Process Control

The screw is the core component of a plastic molding machine, and Topstar enhances screw performance through precision PVD alloy screw head components and meticulous control strategies.

PVD Coated Alloy Screw Head: Physical vapor deposition (PVD) technology is applied to the wear-prone screw head area, creating a hard, low-friction surface that effectively resists wear and thermal softening. For high-temperature applications, PVD coatings prevent dimensional changes and extend service life under the high surface stresses generated when processing materials such as PEEK.

Optimized screw geometry for high-temperature polymers: Topstar offers screw profiles optimized for different material series, with high compression ratios for crystalline polymers, mixing zones for filled compounds, and customized shear sections to promote uniform melting. This geometry ensures complete melting while avoiding excessive shearing, thus preventing polymer chain degradation.

Therefore, Topstar plastic molding machines can not only “reach” high temperatures but also reliably plasticize materials, producing repeatable parts with minimal performance degradation.

Mold temperature controllers suitable for high-temperature mold control

Temperature is also a key factor affecting crystallinity and flowability. Mold temperature control is crucial when processing high-temperature plastics, especially for crystalline or semicrystalline engineering polymers that require higher mold temperatures to achieve the desired crystallinity and dimensional stability. Topstar’s solution is an oil-based mold temperature controller with temperatures up to 320°C, which offers several production advantages:

High set-temperature capability (up to 320°C): Some polymers, such as PEEK and specific LCP grades, require mold temperatures well above those achievable with standard water-cooled or low-temperature systems. Oil-cooled controllers can safely reach and maintain these higher temperatures, ensuring adequate cooling and crystallization of the parts.

Precise temperature control: The PID algorithm of the oil-based mold temperature controller enables strict temperature regulation and minimizes overshoot. This precision maintains the integrity of the polymer molecules and ensures consistency in crystallinity across different cycles and cavities. For optical components or high-strength parts, this consistency translates into better surface appearance and mechanical properties.

Processing specific high-temperature polymers – PC, LCP, PEEK, and PET

Each high-temperature plastic has different characteristics, so matching the injection molding machine performance to the polymer requirements is key to success.

PC: PC requires high melt temperatures for flow and high mold temperatures to reduce internal stress and improve surface finish. With Topstar’s precise melt temperature control and oil-based mold heating, processors can better flow the material into thin-walled geometries and achieve better optical quality. LCP: LCP exhibits good flowability at high temperatures, but requires continuous heating to maintain its anisotropy. The combination of precise barrel control and a mold temperature of 320°C enables manufacturers to maintain polymer orientation and mechanical properties when producing thin, high-performance parts.

PEEK: This is a highly demanding thermoplastic with a high melting point and a narrow processing window. Topstar’s PVD-coated screw assembly, precise melt temperature control, and oil-heated molds enable smooth flow and controlled crystallinity, resulting in parts with excellent chemical and mechanical properties.

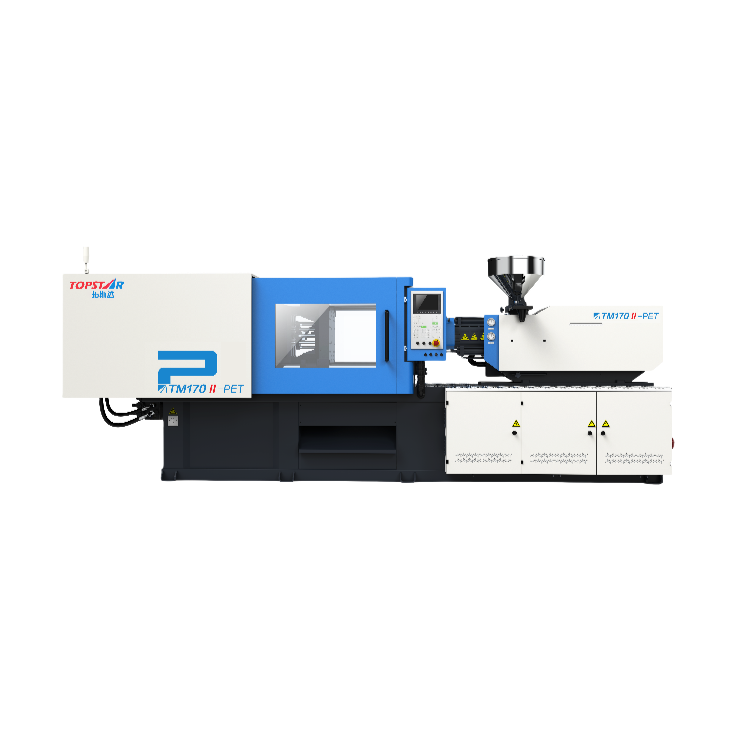

PET: While PET can be processed at moderate melt temperatures, high-viscosity grades of PET used for preform injection molding require high injection pressure and stable screw conveying. Topstar’s TMII-PET series addresses this challenge with oversized hydraulic motors and a drive system designed explicitly for high torque and fast response. Combined with pre-drying and moisture control, Topstar TMII-PET injection molding machines achieve consistent preform quality and minimal hydrolytic degradation.

For these materials, Topstar’s approach reduces polymer chain breakage and degradation, maintains molecular weight, and achieves optimized crystallization.

TMII-PET Series and High-Viscosity PET Preform Molding Capabilities

PET Preform Production: PET preform production, especially with high-melt-viscosity grades, requires a powerful injection system and precise control of screw retraction, injection speed, and holding pressure. Topstar’s TMII-PET series is designed to meet this challenge:

Oversized Hydraulic Motor for Powerful Torque: The TMII-PET injection molding machine features an oversized hydraulic drive unit, delivering the high torque needed for high-speed screw plasticization and rapid injection of viscous melts. This feature prevents short shots and ensures stable screw retraction even under high back pressure.

Dedicated Screw Assembly: The PET-specific screw assembly provides excellent plasticization quality and high efficiency. It reduces plasticization temperature and AA value, effectively improving product shrinkage and increasing transparency. For processors producing high-quality PET preforms, the TMII-PET series equipment reduces cycle variations, improves yield, and minimizes material degradation.

Easily handle high-temperature materials in injection molding.

For processing high-temperature materials, Topstar’s plastic molding machines are equipped with chrome-plated screws, PVD alloy screw heads, precise melt temperature control, high-capacity oil-based mold temperature controllers, and the TMII-PET series. This enables their injection molding machine product line to process a variety of high-temperature plastics reliably. Combined with proper material preparation, process control, and preventative maintenance, it is possible to produce stable, high-quality parts using highly demanding polymers while ensuring uptime and operator safety.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/01/16

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/01/16

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/01/16

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/01/16

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- injection moulding dryer

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar