Fixing Poor Phone Case Mold Opening Accuracy: Mobile Cover Making Machine’s Precision Tuning

2025/12/24 By le zhan

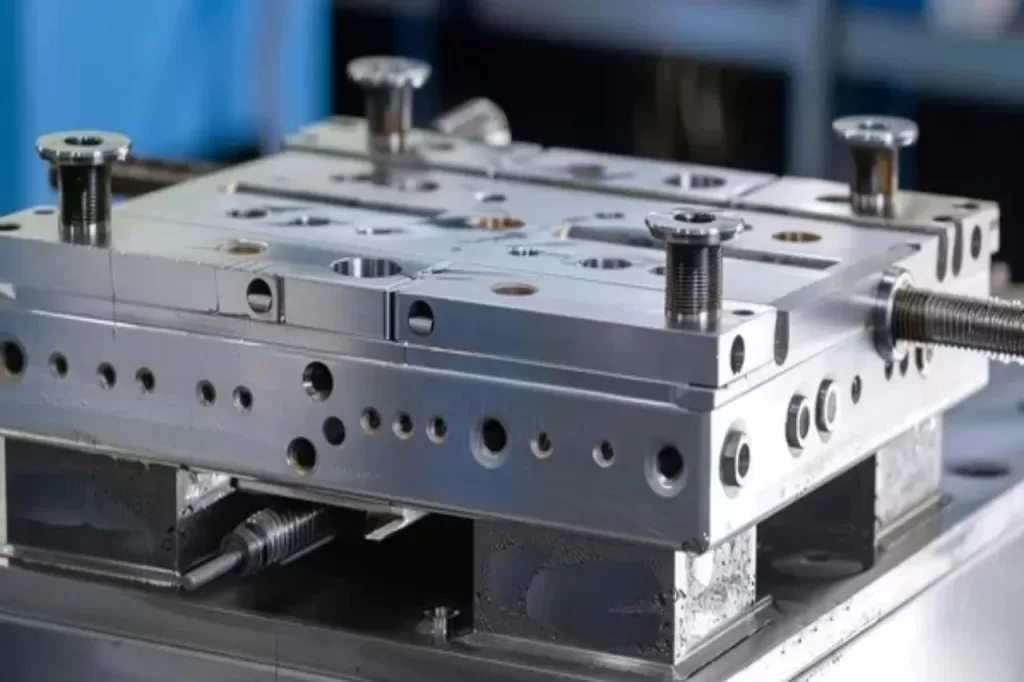

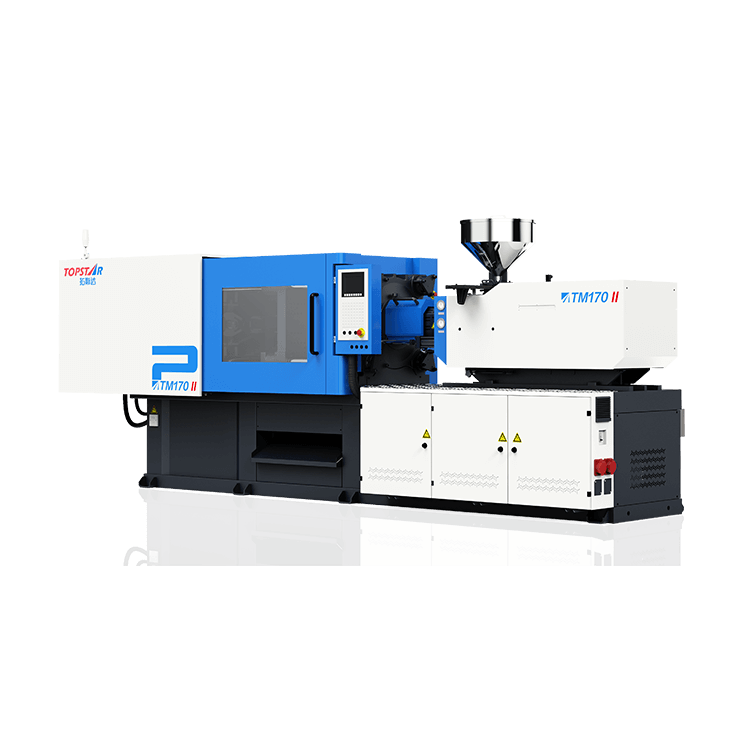

In mobile phone case manufacturing, mold opening accuracy directly affects product quality and stability. Poor mold opening accuracy can lead to defects such as warping, uneven filling, or unstable part quality. For mobile phone case manufacturers, ensuring the highest level of mold opening accuracy is crucial to reducing waste and maintaining product quality. Therefore, a mobile phone case molding machine that delivers reliable, repeatable mold-opening accuracy is essential. We will explain how Topstar’s mobile cover making machine uses a tilting lever mechanism to achieve mold opening position accuracy of ±1mm or less, resulting in faster, more stable mold movement.

The Importance of Mold Opening Accuracy in Mobile cover making machine

Mold opening accuracy directly affects the overall quality of mobile phone cases produced by injection molding machines. Even a mold opening deviation of only a fraction of a millimeter can lead to part misalignment, poor surface quality, or material waste. For mobile phone case manufacturers, high-precision mold opening enables the realization of the precise dimensions and functions required for smartphone accessories.

Factors Affected by Mold Opening Accuracy:

Dimensional Accuracy: Even slight deviations in mold opening accuracy can lead to inconsistent wall thickness, resulting in warping or deformation of the final product.

Production cycle efficiency: Poor mold opening accuracy can lead to delays or require additional cycles to correct alignment, increasing production time and reducing output.

Part integrity: Mold opening deviations can result in incomplete phone cases, leading to defects and higher scrap rates.

Therefore, achieving precise mold opening is crucial not only for producing high-quality phone cases but also for improving production efficiency and reducing costs.

Leading causes of poor mold opening accuracy in the mobile cover making machine

A variety of factors can cause errors in the mold opening process, many of which are related to the setup, design, or maintenance of the mobile cover making machine.

Common causes include:

Machine component wear or misalignment: Over time, components such as guide rails, toggle mechanisms, or mold frames may wear, leading to mold misalignment and decreased accuracy.

Improper toggle setting: An improperly calibrated toggle mechanism can cause uneven mold opening or closing, resulting in mold misalignment. This can occur if the machine’s toggle system is not correctly adjusted.

Mold installation problems: Incorrect mold installation or debris can lead to an uneven mold opening.

Unstable hydraulic or pneumatic pressure: In some injection molding machines, improper pressure settings can cause uneven force distribution during mold opening, reducing accuracy.

By addressing these issues, manufacturers can significantly improve mold opening accuracy, thereby enhancing the overall performance of the mobile phone case manufacturing process.

How to improve accuracy through precision calibration?

To improve mold opening accuracy on mobile cover making machines, regular calibration should be performed during daily production, especially after equipment maintenance, mold replacement, or machine adjustments.

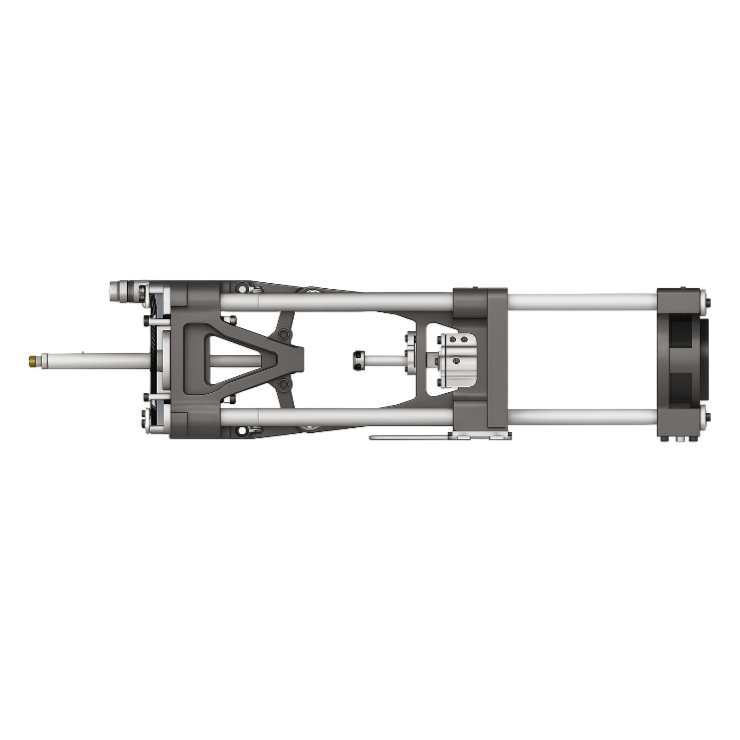

Generally, we can adjust the toggle mechanism. Mobile cover making machines with a tilting toggle layout can achieve precise mold opening. Additionally, ensuring stable hydraulic pressure ensures a balanced distribution of force during mold opening. Therefore, calibration should be performed to ensure that the pressure level is correctly set and maintained during mold circulation. Furthermore, we need to ensure that the two halves of the mold are correctly aligned within the machine. Misalignment will lead to inaccurate mold opening, resulting in defects in the final product. Tighten the mold clamping plates to prevent displacement.

Finally, we need to verify the mold stroke. The machine’s stroke should be calibrated to ensure that the mold opens fully without damaging the mold or the machine. Precise calibration ensures the high-precision opening and closing of the movable cover mold, reducing the likelihood of defects and ensuring part consistency.

Inclined Row Machine Toggle Layout: Achieving Precise Mold Opening

One of the most effective ways to improve mold opening accuracy is to adopt an inclined row machine toggle layout. This design ensures a more stable and controllable mold opening process, offering numerous advantages over traditional toggle mechanisms.

Advantages of the Inclined Row Machine Toggle Layout:

Longer Mold Opening Stroke: The tilting mechanism allows for a longer stroke, which is crucial for molding larger or thicker phone casings. This feature ensures the mold can open fully without compromising accuracy.

Greater Stability: The tilting toggle mechanism provides more stable mold movement, reducing the risk of misalignment during mold opening. This stability is critical for high-precision manufacturing.

Accuracy Up to ±1mm: The tilting layout can control the mold opening position accuracy within ±1mm, which is essential for maintaining dimensional consistency in phone casing production. This accuracy ensures that each part meets specified quality standards.

Faster Mold Movement: The tilting toggle mechanism enables faster mold movement, reducing cycle time while maintaining accuracy. This helps improve production efficiency without compromising part quality.

Impact of Mold Opening Accuracy on Product Quality and Production Efficiency

The accuracy of mold opening directly impacts product quality and production efficiency. For mobile phone case manufacturers, even minor errors in mold opening can lead to serious quality problems, affecting the product’s appearance, functionality, and overall performance.

How Mold Opening Accuracy Affects Product Quality:

Inaccurate mold opening results in poor surface finish, including visible marks, uneven texture, or warping. Additionally, poor mold alignment can cause dimensional deviations in the phone case, affecting its fit, assembly, and compatibility with other components. Ensuring precise mold opening guarantees that every phone case produced meets the exact specifications, reducing the risk of parts exceeding tolerances.

How Mold Opening Accuracy Affects Production Efficiency:

When the mold opens accurately, fewer adjustments or rework are needed, thus shortening cycle time and increasing output. It also results in a lower scrap rate. High mold opening precision reduces the incidence of defective parts, thereby reducing material waste and increasing output. Furthermore, consistent mold opening precision reduces wear on injection molding machines, extends machine life, and minimizes downtime.

Improving Mold Opening Precision for Mobile Phone Cases

In mobile phone case manufacturing, mold opening precision is crucial for producing high-quality, consistent parts. By understanding the factors that affect mold opening precision and implementing appropriate solutions, manufacturers can ensure reliable, efficient production. The key to achieving precise mold opening lies in accurate calibration, proper machine settings, and the use of mobile phone case manufacturing machines equipped with a tilting press elbow. Improved mold opening precision for mobile phone cases helps manufacturers shorten production cycles, improve product quality, and increase production efficiency.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/12/24

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/12/24

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/12/24

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/12/24

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar