Guide to Hybrid Injection Molding Machine: Servo-Hydraulic Synergy for 40% Energy Savings

2025/12/17 By le zhan

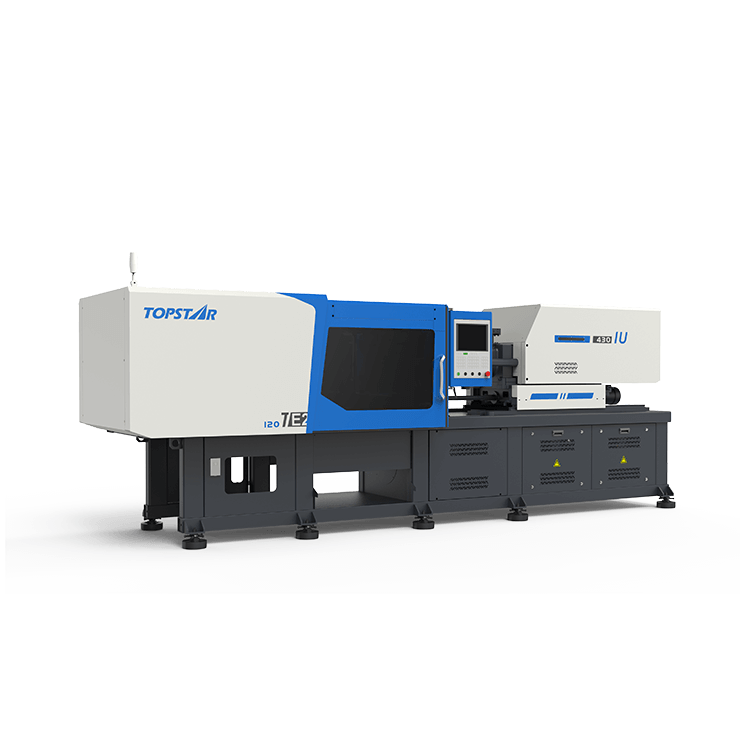

For today’s manufacturers, balancing productivity, quality, and sustainability is crucial. Traditional hydraulic injection molding machines, while reliable, consume a significant amount of energy; all-electric injection molding machines solve the energy problem, but have high initial costs and limited flexibility in heavy-duty applications. A hybrid injection molding machine combines the best of both worlds, integrating the powerful force of hydraulic systems with the efficiency of servo technology. Using servo-hydraulic synergy technology, an average of 40% energy can be saved—without compromising speed, precision, or load capacity.

How does servo-hydraulic synergy technology improve the efficiency of a hybrid injection molding machine?

Traditional hydraulic injection molding machines use a constant-speed motor to drive the hydraulic pump, even when the machine is idle (for example, during part cooling or demolding). This “always-on” design wastes up to 60% of energy. All-electric injection molding machines equip each axis with a servo motor, but they fall short when high torque is required. Hybrid injection molding machines solve both problems by combining servo motors with hydraulic systems; they only activate the motor when pressure is needed and use hydraulic power to handle heavy loads.

Specifically, during injection, the servo motor drives the hydraulic pump to deliver precise pressure, perfectly matching the resin flow requirements. When the machine pauses, the servo motor shuts off, thus stopping energy waste. This synergistic effect is not simply “reducing power consumption,” but rather “smarter energy utilization.”

Precision and Stability Beyond Energy Savings in a Hybrid Injection Molding Machine

Energy savings are its most significant advantage, but the actual value of hybrid injection molding machines lies in the synergy between the servo-hydraulic system and the precision and defect reduction it enables. The stable pressure control of hybrid injection molding machines eliminates uneven filling, which can lead to warping. Traditional hydraulic injection molding machines, due to their constant motor speed, generate excessive flow and release it through relief valves, resulting in energy waste and system instability. Hybrid injection molding machines avoid this by regulating the pump speed with a servo motor, ensuring that the hydraulic pressure remains within ±0.5 bar of the set value.

This stability is crucial for high-precision parts, such as medical syringes or electronic housings, where even a 0.1 mm deviation can render a part unusable. Topstar’s hybrid injection molding machines, under a unified control system, can monitor melt temperature, injection speed, and clamping force, sending the data to the servo controller for fine-tuning during the production cycle. For a consumer electronics customer manufacturing phone cases, this means consistent wall thickness across all 10,000 phone cases produced per shift—something their previous hydraulic injection molding machines couldn’t achieve.

Suitable for a Wide Range of Injection Molding Applications

A common misconception about hybrid injection molding machines is that they are only suitable for specific materials or part sizes. In fact, the servo-hydraulic synergy makes them one of the most versatile injection molding machines on the market. They can handle a wide range of products, from miniature electrical connectors (using PP resin) to large industrial containers (using HDPE).

The key lies in the adjustable servo-hydraulic curves: operators can set different pressures and speeds for each material—harder resins require higher pressure. In contrast, flexible TPU requires a gentler approach. Additionally, the servo system coordinates the injection of each component with millisecond precision, ensuring perfect bonding. Unlike all-electric injection molding machines, which may struggle to handle the torque required for large molds, hybrid injection molding machines maintain speed and precision across all applications, making them an ideal solution for diverse production needs.

How to Simplify Your Workflow?

Topstar hybrid injection molding machines feature an intuitive touchscreen interface for easy adjustment of servo-hydraulic parameters. For custom materials, the system allows users to save profiles so they can complete repetitive jobs with a single touch. The system also integrates predictive maintenance alerts: sensors monitor servo motor temperature, hydraulic oil condition, and pump performance, and send notifications before problems occur. It can also connect to factory IoT systems, allowing managers to track energy usage, cycle times, and defect rates in real time. This transparency helps identify inefficiencies—for example, if a shift uses more energy than usual, managers can check whether they have set the servo-hydraulic profile correctly. By combining advanced technology with user-friendly design, hybrid injection molding machines not only save energy but also make your entire production workflow smoother and more reliable.

Sustainability: Better Aligned with Your ESG Goals

Today’s manufacturers are focused not only on costs but also on sustainability and ESG goals. Hybrid injection molding machines help you achieve these goals by reducing energy consumption by 40% (and thus reducing carbon emissions). For a 500-ton injection molding machine operating 24/7, this means a reduction of 126 tons of CO2 emissions per year – equivalent to the carbon emissions of 27 cars. Hybrid injection molding machines also reduce hydraulic oil waste: traditional hydraulic machines lose hydraulic oil through overflow valves and leaks. In contrast, hybrid systems use less total hydraulic oil and have better sealing. Topstar’s hybrid models use biodegradable hydraulic oil, further reducing their environmental impact. At the same time, their energy efficiency meets the requirements for government incentives.

Improved Efficiency and Reduced Energy Consumption

Hybrid injection molding machines combine energy saving, improved quality, simplified operation, and support for sustainable development. Through servo-hydraulic collaborative technology, they achieve 40% energy savings. Whether you produce automotive parts, medical devices, or consumer goods, hybrid injection molding machines can meet your needs, reduce waste, and improve your production profitability.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/12/17

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/12/17

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/12/17

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/12/17

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar