How can hopper dryers improve the quality and stability of plastic products?

2026/01/12 By le zhan

Trace amounts of moisture in plastic material granules can lead to surface defects, insufficient weld line strength, and inconsistent dimensions. Hopper dryers address this problem by removing moisture before molding, but not all perform equally well. The right dryer design, control logic, and installation can directly improve the quality and consistency of plastic products. Therefore, we will show you how Topstar’s hopper dryers improve the quality and consistency of plastic products, delivering stable, consistent cycle performance.

Using Hopper Dryers to Remove Moisture for Stable Melt Behavior

Moisture in plastics alters melt viscosity and chemical properties during the molding process. When water in the barrel turns into steam, it can cause micropores, splashing, and hydrolytic degradation in sensitive polymers such as PET, PBT, and polycarbonate. Hopper dryers prevent these problems by raising the resin temperature and circulating hot, dry air within the hopper until the moisture content meets the target specification.

First, the heating power and airflow rate of the hopper dryer determine the drying kinetics. Efficient hopper dryers produce a uniform, upward airflow of hot air that penetrates the entire material layer, preventing channeling and insufficient drying. Second, continuous moisture removal ensures stable melt viscosity. When the resin enters the barrel with a stable moisture content, the melt and heat distribution curves generated by screw shear are repeatable. This translates into stable injection weight, stable gate solidification time, and a predictable cooling process.

Precise Control with PID Self-Tuning for Improved Repeatability

Control quality is just as important as heater power. PID controllers regulate temperature by adjusting the heater output to maintain the target setpoint. Traditional PID loops often require manual tuning, which is both time-consuming and error-prone. Topstar’s hopper dryer is equipped with PID self-tuning, which automatically adapts to the system’s thermal dynamics.

Why is this important? The auto-tuning function optimizes controller gains based on specific load, airflow resistance, and ambient conditions. It reduces overshoot after setpoint changes and lowers steady-state errors. This means the hopper air temperature remains within tight tolerances, preventing batch-to-batch variations caused by periodic moisture ingress or partial drying. In practice, PID adaptive tuning shortens setup time during material changes, simplifies operator work, and reduces the risk of human error. Simultaneously, it also supports temperature control of hygroscopic resins (precisely controlled within ±1–2°C), enabling consistent part quality over extended production runs.

Hopper Dryers with Hot Air Up-Blowing Diffusion Device

The airflow distribution geometry of a hopper dryer fundamentally determines the uniformity of its drying performance. Many low-quality dryers produce vertical airflow that creates preferential paths, resulting in insufficient drying of some materials. The hot air up-blowing diffusion device solves this problem by evenly distributing air across the material layer and creating a consistent airflow velocity throughout the hopper.

This upward diffusion achieves three objectives. First, it prevents channeling effects; second, it ensures that the upper layer of particles does not remain cold while the lower layer overheats; uniform residence temperature minimizes localized overheating, thus preventing degradation of sensitive resins. Third, it accelerates drying by maximizing the contact area between hot air and each particle, thereby improving convective heat transfer and moisture mass transfer. This practical benefit results in shorter, more predictable drying cycles and reduces unexpected issues during material changes or product production.

Drying Temperature Control Circuit with Over-Temperature Protection to Safeguard Resin Quality

Overheating events can damage resins and introduce new variability. Degraded polymers can alter viscosity and mechanical properties; charring or partial melting in the hopper can lead to extrusion blockages or defective parts. Reliable hopper dryers employ multiple layers of protection to prevent overheating and maintain material integrity.

Topstar’s hopper dryers incorporate over-temperature protection in their drying temperature control circuit. This circuit monitors not only air temperature but, in many designs, also material temperature or probe feedback. If an uncontrolled condition is detected, the protection logic reduces or cuts off heater power and triggers an alarm. This protects the resin from thermal degradation and gives operators time to take action before quality is affected. Furthermore, features such as thermal fuses, independent high-temperature limiters, and redundant sensors enhance safety. From a quality perspective, preventing microscopic thermal damage ensures the polymer’s molecular structure remains consistent, which directly affects melt flow rate and mechanical properties.

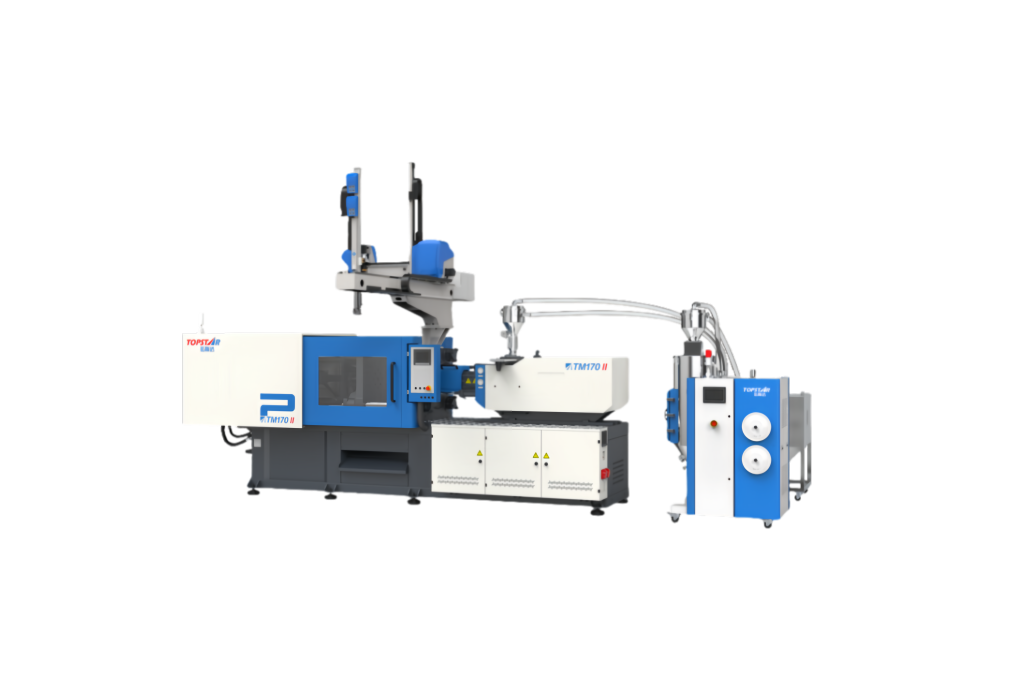

Integration with Other Injection Molding Equipment

Hopper dryers are not standalone equipment; they must be integrated with the other injection molding equipment. Proper integration reduces variations in material residence time, cross-contamination, and batch-to-batch inconsistencies.

First, control the material feed rate and hopper filling schedule. The dryer must maintain sufficient residence time for the specific resin and batch size—too short a residence time leads to incomplete drying; too long a residence time can lead to thermal degradation of some polymers.

Second, use dedicated production lines for different materials or employ color-coded hoppers to prevent cross-contamination. When switching material grades, follow validated purging and drying procedures. Topstar dryers support rapid recipe switching and programmable setpoints, simplifying the material changeover process while ensuring effective drying. Third, synchronize the dryer’s operation with the Manufacturing Execution System (MES). The factory control system should display real-time status, alarm logs, and drying history. This facilitates traceability: if a quality issue arises, you can review historical drying data, sensor logs, and PID performance to identify the root cause quickly.

Ensuring Long-Term Product Quality Stability

Topstar’s universal hopper dryers are equipped with PID self-tuning functionality and an upward-blowing hot air diffusion device, ensuring uniform material drying and accelerating the drying process. Furthermore, its drying temperature control circuit includes over-temperature protection, improving drying efficiency and guaranteeing the quality standards of the final product. Finally, synchronizing them with the MES enables traceability, allowing for quick identification of the root cause.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/01/12

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/01/12

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/01/12

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/01/12

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar