How can linear robots increase cycle output in thin-wall injection molding?

2025/08/27 By le zhan

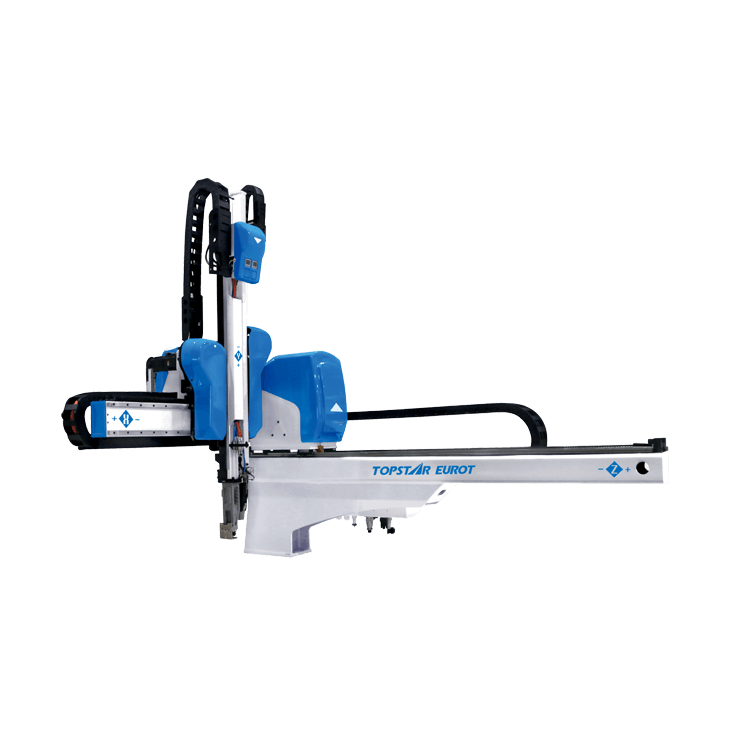

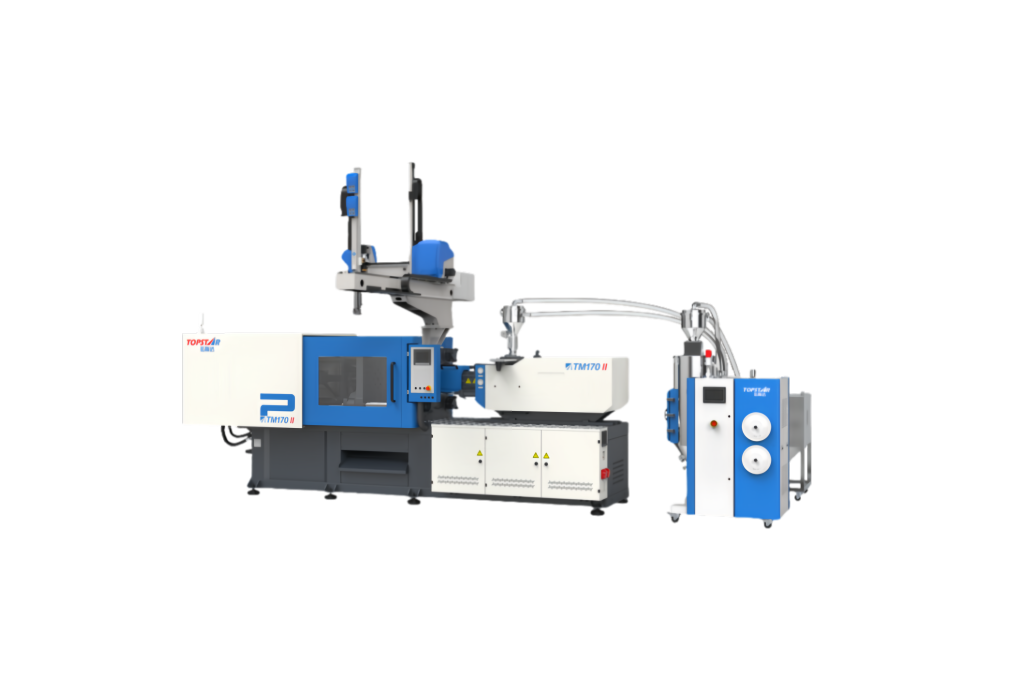

How can linear robots improve cycle yield in thin-wall injection molding? From a production management perspective, synchronization, precision, and a carefully designed weight-to-strength ratio are essential. Topstar’s EU Series AC Servo Injection Robots feature integrated vibration suppression, making them particularly suitable for molding thin-walled products susceptible to mold release disturbances. They can also directly receive signals from the host injection molding machine, enabling integrated operation. In turn, the linear robot’s control system automatically optimizes the demolding process, streamlining pick-and-place times and reducing cycle variation on the production line.

Importantly, Topstar equips these linear robots with a unified communication language, enabling proper device connectivity and deterministic process control. Finally, the EU series utilizes lightweight, high-strength A6061 aluminum alloy for its mechanical structure. This choice increases top speed by approximately 10%, reduces acceleration and deceleration times by approximately 20%, and directly improves cycle output, all while maintaining the rigidity and precision required for thin-wall injection molding.

Linear robots offer more precise motion control

The most direct way for a linear robot to improve cycle yield in thin-wall injection molding is to ensure stable motion during the critical demolding window. Thin-walled parts have low structural stiffness before cooling and are easily deformed by transient forces. Topstar’s EU series AC servo linear robots incorporate vibration suppression in the servo drive to flatten the step response and minimize overshoot during start/stop transitions. This level of control ensures that mechanical shock remains below the threshold that could otherwise cause thin-walled parts to sag or deform.

Furthermore, precise end-effector motion reduces part handling variability. Accurate path planning and fine-tuning prevent excessive contact forces when the linear robot picks up newly molded, thin-walled parts. As a result, molds experience less atypical loads, extend mold life, and reduce scrap due to handling defects.

Linear robots supporting host signals, unified communication, and synchronized operation

A linear robot operating in isolation cannot maximize cycle output; it must operate as part of a coordinated system. Topstar’s linear robots receive signals from the host injection molding machine and share a consistent, unified communication language with peripheral devices. This integration eliminates ambiguous handshakes and timing uncertainties that can cost milliseconds or create race conditions during the demolding process.

Synchronous operation begins with deterministic I/O and communication protocols. When the injection molding machine signals “cavity ready,” the robot initiates a coordinated sequence based on the clamping motion and mold opening angle. Because the linear robot and injection molding machine are synchronized on a specific event, they can begin pre-positioning micro-movements before the final mold opening stroke, reducing downtime and increasing cycle output.

Advantages of Lightweight A6061 and Higher Cycle Output

Mechanical design also has a direct impact on dynamic performance. Topstar’s choice of A6061 for EU series structural components offers practical advantages for thin-wall injection molding. Reduced moving mass means lower inertia, enabling linear robots to achieve higher top speeds and accelerate or decelerate faster while maintaining positioning accuracy. Quantitatively, this results in an approximately 10% increase in top speed and a 20% reduction in acceleration/deceleration times, resulting in shorter robot cycle times and a higher number of effective cycles per hour.

Lower moving mass also reduces transmitted vibration. Because inertial forces are proportional to mass and acceleration, the A6061 structure generates less reaction loads on the robot frame and mold during rapid motion. Combined with the vibration suppression control algorithm described earlier, this results in smoother operation, which means fewer micro-tearing and improved geometric fidelity of part edges.

Increasing Output and Throughput in Thin-Wall Injection Molding

Properly designed and integrated linear robots can transform thin-wall injection molding from a fragile process into a robust, high-yield operation. Topstar’s EU series AC servo injection robots enhance cycle throughput in molding by suppressing vibration, utilizing direct host signals, and implementing unified communications for synchronized operation. The robots feature a lightweight A6061 structure for faster dynamic response and an adaptive control strategy that balances speed with part integrity.

Related Questions and Answers

Q1. What exactly does vibration suppression do in the thin-wall part molding process?

A1: Vibration suppression reduces transient accelerations and mechanical vibrations during linear robot motion. Vibration suppression smoothes step response and reduces overshoot, preventing dynamic forces from damaging thin walls.

Q2. Can linear robots really reduce cycle times without increasing scrap rates?

A2: Yes. When using adaptive motion profiles and synchronized signals with the press, they can perform pre-positioning, segmented extraction, and overlapping peripheral tasks. These strategies can reduce non-productive time without prematurely processing parts.

Q3. How important is unified communication between the injection molding robot and the injection molding machine?

A3: Critical. Unified communication eliminates ambiguous motion, ensures deterministic timing for pick-and-place actions, and enables the robot to respond to real-time machine conditions, such as cavity pressure and mold temperature, thereby enhancing overall productivity.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/08/27

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/08/27

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/08/27

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/08/27

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- injection moulding dryer

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar