How to analyze the causes of horizontal injection molding machine failures?

2025/05/26 By Topstar

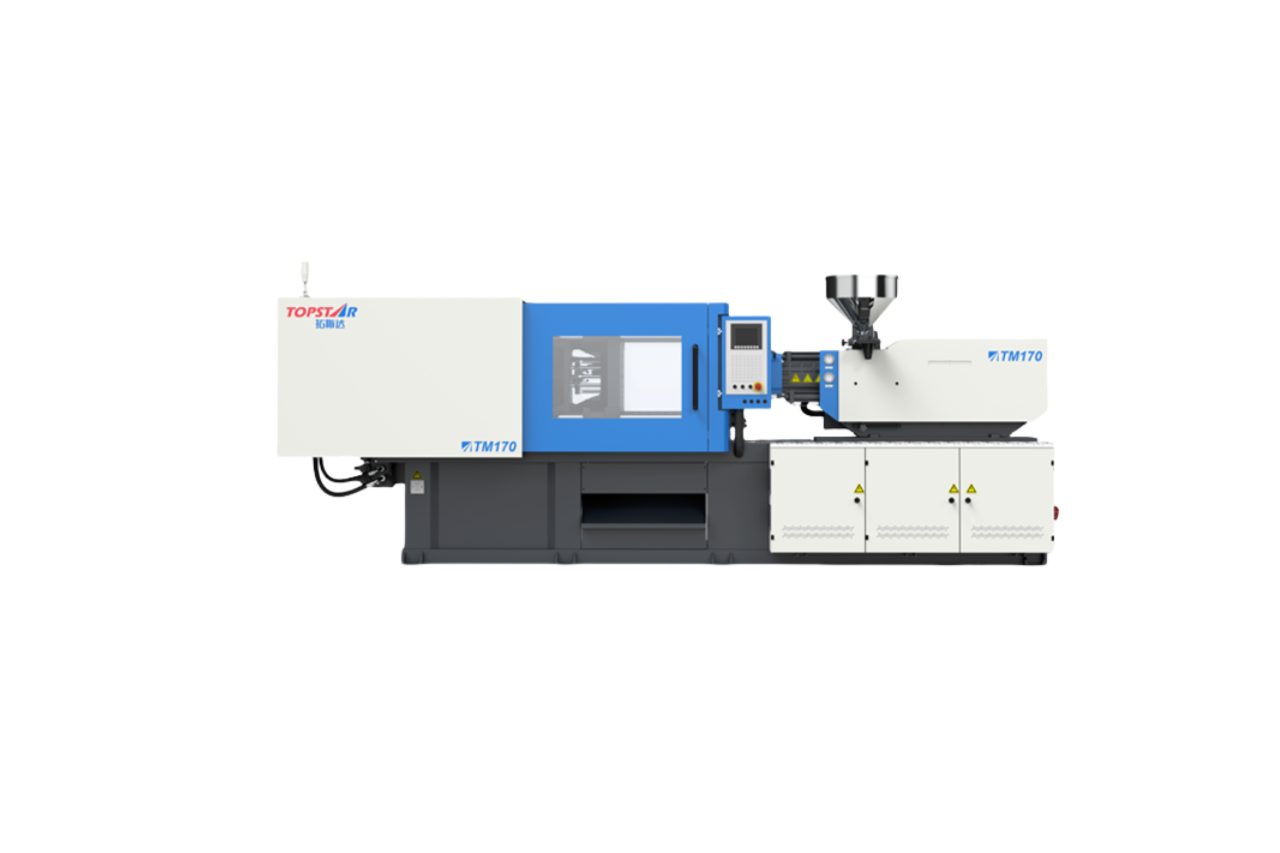

Over time, horizontal injection molding machines will experience production interruptions due to mechanical, hydraulic, electrical, or process-related problems. Identifying horizontal injection molding machine failures requires a systematic approach that includes identifying failure symptoms and collecting data to identify the root cause. We will summarize several failure issues, including mechanical components, hydraulic systems, electrical controls, process parameters, etc., to provide plastic product manufacturers with practical insights to help maximize uptime, reduce scrap, and optimize overall equipment efficiency.

Wear and misalignment of the mechanical components of the horizontal injection molding machine

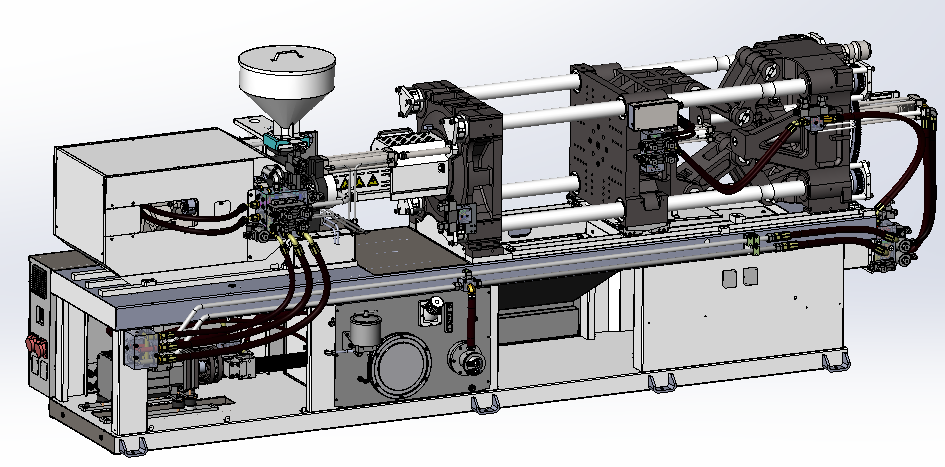

Mechanical failures often stem from wear or misalignment of key components of horizontal injection molding machines – tie rods, plate guides, elbows, and ball screws are subject to repeated load cycles that cause fatigue or corrosion over time. Symptoms include abnormal vibration, uneven clamping force, mold wear patterns, and increased cycle times. Therefore, we can use precision alignment tools to measure plate parallelism and detect shaft clearance using laser trackers, micrometers, and feeler gauges. At the same time, the clearance of the toggle joint and pivot pin is checked, combined with lubrication audit and hardness testing of wear surfaces to identify hot spots before failure occurs. High-strength steel tie rods and high-rigidity linear guide surfaces are used in Topstar’s horizontal injection molding machines. Combined with regular vibration analysis and grease sampling, mechanical performance degradation can be minimized.

Hydraulic system failure of a horizontal injection molding machine

Hydraulic problems are another common failure problem of horizontal injection molding machines. Seal leakage, filter blockage, or proportional valve failure usually manifests as slow clamping, inconsistent injection speed, or complete pressure loss. Therefore, the operator may notice unstable platen movement, pressure fluctuations on the digital instrument, or a sudden increase in oil temperature. Thus, a hydraulic audit is required, and fluid analysis is necessary to check viscosity, particle contamination, and water content to determine whether deterioration requires fluid replacement. Next, technicians must check the hydraulic pump for cavitation, verify the safety valve setting, and clean or replace the clogged suction filter. Topstar’s hydraulic design has high-response servo valves, high-efficiency multi-stage filtration, and condition-based maintenance alarms to provide stable pressure control and minimal downtime. Regular hydraulic maintenance can maintain accurate clamping and injection curves.

Electrical Control and Sensor Failure

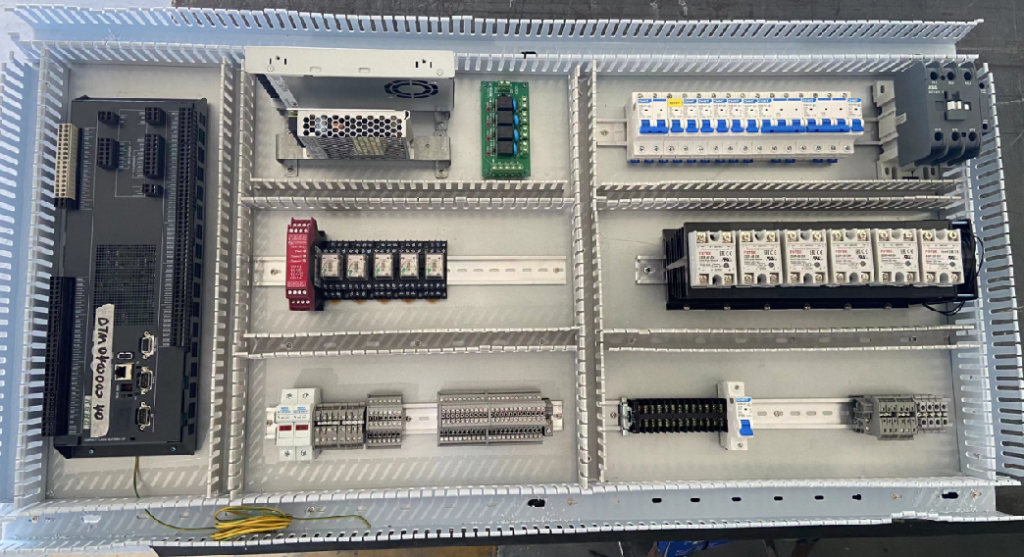

Horizontal injection molding machines rely on an electrical system PLC, HMI, servo drive, and sensors to control every movement and process parameter. Any sensor or wiring harness failure may interrupt the injection cycle or affect safe operation. Alarms such as “no charge,” “position error,” or overcurrent indication usually indicate encoder failure, limit switch misalignment, or abnormal servo drive voltage. Therefore, we can conduct a step-by-step troubleshooting electrical diagnosis, which includes verifying power supply voltage, checking grounding and shielding integrity, and testing sensor output and signal quality with a multimeter or oscilloscope. If conditions permit, you can upgrade to shielded industrial-grade cables and implement strong cable management to prevent interference and wear.

Process Parameter Deviation

Even if the hardware is perfect, wrong process parameters can cause apparent failures in horizontal injection molding machines. When the melt temperature is too high, it will cause polymer degradation and nozzle clogging. Insufficient back pressure will cause poor melt mixing and lack of material, and improper injection speed or holding time will trigger pressure alarms or incomplete filling. Therefore, operators must regularly verify parameter settings against recommendations and record any deviations. Data logging systems can record real-time injection pressure, screw position, barrel temperature profiles, and cycle times for historical trend analysis. In addition, a solid commissioning protocol for each new mold should include test runs, plotting optimal temperature profiles, and locking settings to prevent out-of-tolerance conditions.

Material and moisture-related issues

Inconsistencies in raw materials often masquerade as mechanical or hydraulic failures in horizontal injection molding machines. For example, wet, hygroscopic resins can bubble in the barrel, causing erratic pressure readings, erratic screw recovery, and poor part quality. We can perform comprehensive material audits, including verification of batch traceability, pellet shape, and moisture content through infrared analyzers or moisture meters. Topstar ensure consistent melt quality by integrating precise drying systems, hopper dehumidifiers, and automatic gravimetric feeders. In addition, our barrel and screw designs mitigate moisture-related defects. Regular material handling, such as hopper cleaning, can further reduce the risk of contamination. By strictly controlling material handling and pre-drying, you can avoid erratic injection behavior and extend the life of the screw and barrel on horizontal injection molding machines.

Holistic Failure Analysis Approach

Diagnosing and preventing horizontal injection molding machine failures covers checking mechanical integrity, hydraulic system health, electrical reliability, process optimization, material quality, and more. By systematically auditing each injection molding machine component and leveraging real-time monitoring data, plastic product manufacturers can minimize unplanned downtime, reduce scrap rates, and ensure the reliability of their horizontal injection molding machines.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/05/26

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/05/26

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/05/26

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/05/26

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar