How to Choose an Injection Molding Robot for High-Precision Products: HDW’s High-Speed Response

2025/11/19 By le zhan

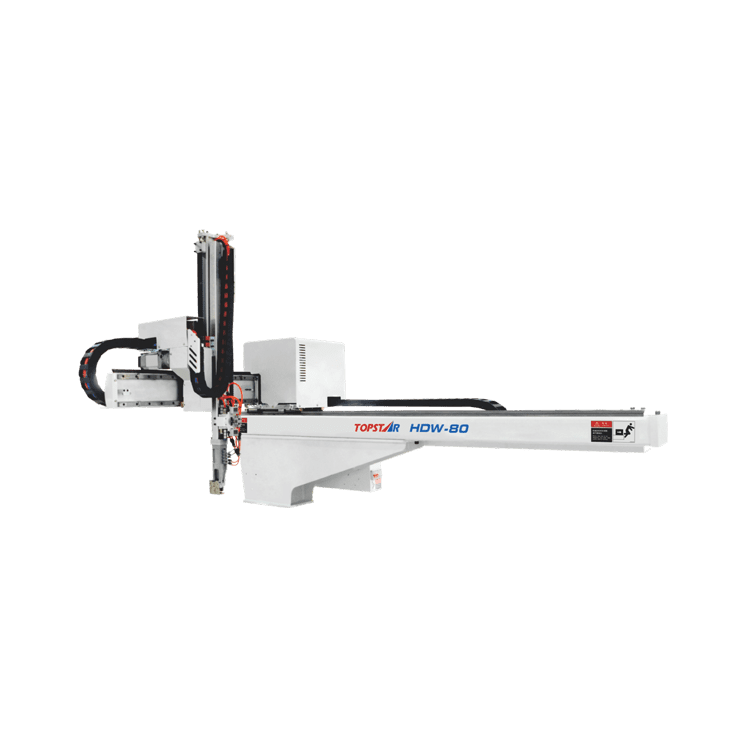

Suppose an injection molding robot cannot maintain stable positioning, resulting in microscratches on parts and non-standard dimensions. In that case, it not only wastes significant production time and costs but also compromises part quality. Therefore, for high-precision applications and scenarios with stringent appearance requirements, specialized injection molding robots are necessary. Topstar’s HDW series, designed specifically for use with 75-1300 ton horizontal injection molding machines, offers high-speed response and precise positioning, and features three-axis motion, AC servo drives, and rigid guideways. These characteristics effectively handle the production of injection-molded products with strict tolerances and extremely high surface finish requirements.

Why do high-precision products require specialized injection molding robot?

High-precision products, such as microelectronic connectors (tolerance ±0.005 mm), medical implants, or aerospace fasteners, push injection molding technology to its limits. Unlike standard parts, high-precision injection molding robots need to meet three requirements:

Micron-level precision: Even tiny positioning errors (above 0.01 mm) can ruin a part. The robot must be precisely aligned with the mold in each cycle to avoid dimensional deviations or surface damage.

Stable movement: Vibration or jitter can be transmitted to the mold or part, causing defects or warping. The robot’s movement must be smooth and consistent.

Speed and precision in balance: High-precision injection molding typically uses fast cycles (5-10 seconds). The robot must quickly remove parts to avoid cooling deformation without compromising precision.

Perfect control: Precision parts cannot withstand rough gripping or misalignment—the robot needs gentle, controllable movement.

General-purpose injection molding robots cannot meet these requirements: they are designed for mass production, not high-precision manufacturing. In contrast, the HDW series prioritizes precision from the outset. “The key to high-precision injection molding lies in eliminating variables,” explains the head of R&D at Toptsar Robotics. “HDW eliminates this variable—its performance is predictable, repeatable, and precise.”

HDW Series Injection Molding Robot, Compatible with 75-1300 Ton Horizontal Injection Molding Machines

The first step in choosing an injection molding robot for high-precision injection molding operations is ensuring it is compatible with your injection molding machine. The HDW series integrates seamlessly with horizontal injection molding machines ranging from 75 to 1300 tons:

75-200 Ton Class: Ideal for manufacturing micro-precision parts (e.g., electronic pins with a diameter of 0.5 mm). HDW’s compact design allows it to fit into production lines with limited space, while its precision matches the machine’s micro-molding capabilities.

200-500 Ton Class: For processing medium-sized, high-precision parts. HDW’s extended reach can handle multi-cavity molds without compromising alignment accuracy.

500-1300 Ton Class: Suitable for large, precision parts. The robust construction of HDW machines matches their powerful machining capabilities, enabling efficient processing of heavy, high-precision parts.

This broad compatibility means manufacturers can improve precision without replacing existing injection molding machines. HDW also excels at dual tasks: it can remove finished high-precision parts and mold gates in a single cycle, eliminating the need for secondary finishing and reducing handling-related defects by 40%.

Single-stage and telescopic versions – achieving flexibility for precise setup

High-precision production lines vary in terms of space, mold design, and part dimensions. Therefore, the HDW series offers two versions to accommodate various situations, both optimized for vertical movement to complement high-precision molding:

Single-stage version: Standard 900 mm vertical travel (expandable to 1100 mm). Ideal for production lines with ample vertical space, providing direct, rapid access to the mold.

Telescopic version: Offers 900 mm or 1100 mm vertical travel, with a telescopic arm that extends horizontally to reach deep molds or confined spaces. This is crucial for high-precision parts in multi-cavity molds.

Both versions maintain HDW’s consistent precision and speed; the only difference lies in the entry and exit methods. Topstar’s application engineers will help you choose the version best suited to your equipment, measuring mold depth, machine clearance, and part dimensions to recommend a single-stage or telescopic entry and exit method, ensuring the robot works seamlessly with your process flow.

Three-Axis Motion and AC Servo Drives—Speed and Precision Combined

High-precision molding requires speed to avoid cooling defects, but speed cannot come at the expense of precision. The HDW series achieves a balance between these two thanks to its three-axis motion system and high-performance AC servo motors:

Three-Axis Motion: The robot can move along the lateral, longitudinal, and spindle axes, covering all the movements required to enter the mold and remove the part. This coordinated motion eliminates redundant steps, reducing part removal time to 0.8 to 1.5 seconds, which is sufficient for a 5-second molding cycle without compromising alignment accuracy.

AC Servo Motors: These motors provide instant, precise torque control, enabling the HDW to accelerate smoothly and stop within ±0.005mm of the target position. Unlike hydraulic robots or stepper motors, AC servo motors ensure precise control of every movement—crucial for machining high-precision parts.

In Topstar’s lab tests, the HDW series robots achieved a repeatability of ±0.01 mm, far exceeding the general robot industry average of ±0.05 mm. This three-axis design also enables gentle operation: the injection molding robot decelerates as it grips a part. It accelerates once it leaves the mold, preventing damage to delicate, high-precision components.

High-rigidity guideways and open servo positioning achieve higher precision.

While speed and compatibility are critical, true high precision relies on two core features of the HDW: high-rigidity guideways and an open servo positioning control system. Together, these eliminate vibration and ensure consistent accuracy.

Through high-rigidity guideways, the HDW’s robotic arm runs on precision-machined, reinforced rails, effectively resisting bending and vibration. Even at full speed, the robot’s movement is remarkably stable—no wobbling, no deviation. This is crucial for surface-sensitive parts, as even the slightest scratch is unacceptable. The open servo positioning control system dynamically adjusts the robot’s position using real-time feedback from mold sensors. It compensates for minor mold wear, temperature changes, or machine vibrations, maintaining a positioning accuracy of ±0.008mm. This level of adaptability is crucial for parts with extremely high tolerance requirements. Topstar’s field data confirms this: factories equipped with HDW equipment report a 65% reduction in precision-related defects compared to factories using conventional injection molding robots.

Delivering stable, high-precision product output

High-precision products require injection molding robots that can not only remove parts but also maintain their integrity. The HDW series perfectly achieves this goal with its broad compatibility (suitable for 75-1300 ton injection molding machines), flexible dual-version design, three-axis AC servo drive motion, and ultra-high-precision positioning system. It eliminates the possibility of the robot itself being a source of defects, transforming unstable production into reliable, high-quality output.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/11/19

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/11/19

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/11/19

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/11/19

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar