How to prevent the screw of plastic injection molding machine from slipping?

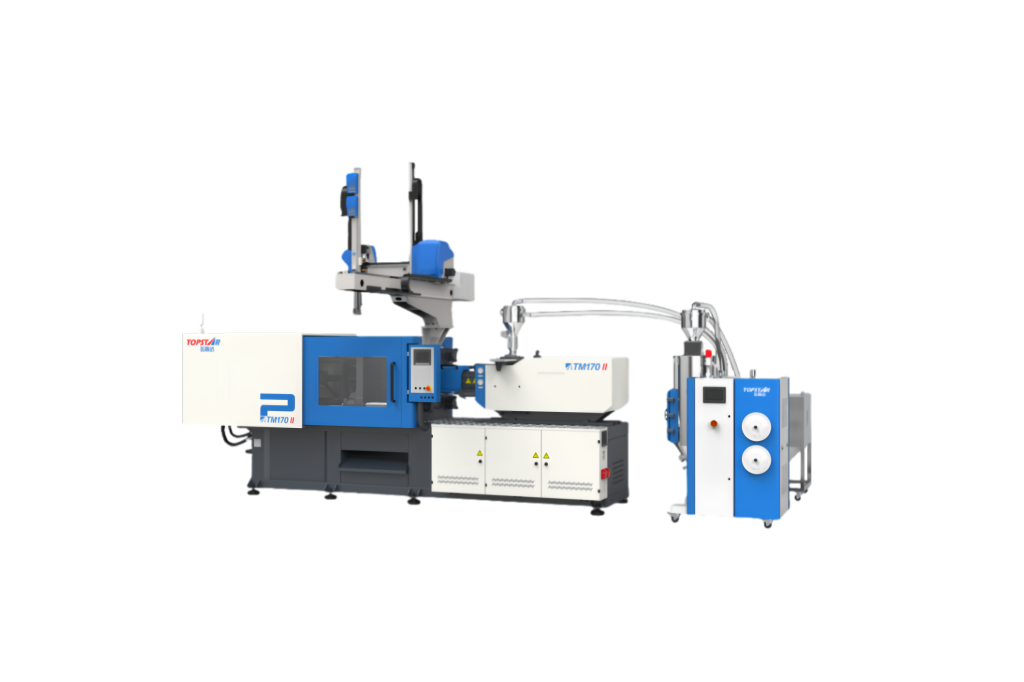

- Horizontal Injection Molding Machines

- large injection molding machine

- Plastic injection molding machine

- Plastic Injection Molding Machines

2025/06/09 By Topstar

Screw slippage in plastic injection molding machine poses a serious threat to process stability and part quality. Slippage occurs when the screw’s flights lose their grip on the molten polymer in the barrel, resulting in inconsistent shot sizes, poor melt homogeneity, and fluctuating injection pressures. First, identify the symptoms, which typically manifest as a sudden drop in injection pressure, varying shot weights, and streaking or underfilled parts. Next, determine the root cause, which can be a worn drive coupling, reduced screw-barrel clearance, a failed check ring, or improper back pressure setting. By deciding how each component affects screw pull, injection molding machine operators can implement targeted strategies to maintain strong melt delivery and adhere to high-quality production standards.

Inspecting and Maintaining Drive Couplings for Plastic Injection Molding Machine

The drive coupling between the servo or hydraulic motor and the screw shaft plays a critical role in the torque transfer of these horizontal injection molding machines. Suppose the coupling’s elastomeric elements degrade, crack, or shift under load. In that case, the motor cannot fully transfer its rotational force to the screw, which causes it to slip when processing high-viscosity-filled resins or large shot sizes.

First, disconnect the power to the machine, remove the coupling cover, and inspect the flexible cross shaft or bushing for signs of fatigue. Next, manually rotate the motor and screw to detect axial or radial play. Axial play exceeding 0.05 mm usually requires immediate replacement. When installing a new coupling, use a feeler gauge or laser alignment tool to verify angular alignment according to the corresponding tolerance. Finally, ensure that the torque of the coupling bolts is within specifications and reapply the corresponding anti-corrosion protective coating.

Maintain the integrity of the screw and barrel of the plastic injection molding machine.

Wear between the screw threads and the barrel bore reduces the mechanical grip required to convey the polymer forward, especially when high back pressures are high or abrasive fillers are used. Whether on a large injection molding machine or a standard plastic molding machine, the continued wear of glass fiber, talcum powder or pigment additives will accelerate wear and push the screw-barrel clearance beyond acceptable limits. Therefore, you can disassemble the screw every 1,000 to 2,000 production hours. Clean the adhered polymer with a solvent, and measure the thread height with a micrometer. If the measurements are outside the wear tolerance, you have two options: refurbish the screw and barrel, or replace them entirely. For demanding injection molding, consider upgrading to a hardened alloy barrel or ceramic-coated screw, technologies that can significantly reduce long-term wear.

Ensure the performance of check rings and check valves.

Check rings and check valves to prevent melt backflow during the high-pressure injection stage. When these parts wear or the return spring fatigues, the melt may bypass the advancing threads, causing “screw slippage” even if the motor and coupling are functioning correctly. When maintaining the check device on the plastic injection molding machine, you can disassemble the check ring housing, clean all components, and inspect the ring surface and spring cavity. Check for uneven contact, corrosion pitting, or spring breakage. Alternatively, replace the damaged ring or spring with the specified part, ensuring that the outer diameter of the replacement ring matches the micro-tolerance of the barrel.

After reassembly, perform a quick check by manually rotating the ring forward and backward: the ring should slide backward but lock firmly in the forward direction under moderate torque. By maintaining the integrity of the check ring, you can prevent the melt column of the plastic molding machine from backflowing, thus eliminating a common cause of screw slippage.

Optimizing Back Pressure and Screw Speed

Back pressure and screw speed directly affect the melt viscosity and mechanical grip of the injection molding machine. Too little back pressure during plasticization will result in a thin melt column that may “slip” through the screw flights; conversely, too much back pressure will overload the drive components and limit production. On plastic injection molding machines, the ideal back pressure is usually between 5% and 10% of the peak injection pressure, adjusted in increments of 5 to 10 bar.

Similarly, moderate screw speed strikes a balance between reducing residence time and maintaining traction. When the system runs at high speed, it introduces shear heating and reduces purchase power, while low speed increases the cycle time. When using a plastic injection molding machine for engineering polymers or high-viscosity compounds, it may be necessary to fine-tune further and combine incremental speed adjustments with back pressure adjustments to achieve a stable torque curve and uniform melt temperature.

Adjust with servo drive control system

Traditional hydraulic systems are robust but lack the dynamic feedback needed to respond to slip events. In contrast, servo-driven injection units provide precise torque control, instantaneous response to changing melt loads, and other intelligent monitoring capabilities. Using servo-driven or all-electric plastic injection molding machines, built-in slip detection functions can be implemented.

Additionally, in Topstar’s injection molding machines, proportional back pressure control, screw speed, and barrel temperature can be adjusted in real-time to maintain optimal melt viscosity and traction. This level of intelligence can not only prevent slippage but also shorten startup time and reduce scrap. As these large injection molding machines handle multi-material or high-fill applications, intelligent drive devices ensure that the screw does not “overtake” the melt.

Preventing screw slippage through multiple dimensions

Screw slippage can compromise the core function of plastic injection molding machines. By maintaining the integrity of the drive coupling, the condition of the screw barrel, the performance of the check ring, and the optimized back pressure and speed, as well as the use of servo drives, slippage can be effectively prevented in actual production. Additionally, proactive maintenance programs with real-time monitoring can also help ensure the early detection of wear or misalignment, which in turn helps keep your plastic injection molding machine running smoothly.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/06/09

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/06/09

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/06/09

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/06/09

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar