How to Resolve Plastic Molding Part Weight Variations from Pressure Control?

2025/11/17 By le zhan

At an automotive parts injection molding plant, 10,000 semi-finished sensor housings were left idle due to a 0.5-gram weight deviation in the plastic injection molding process. “We’ve adjusted the pressure knob 50 times today,” their production manager said. “One batch is too light, the next too heavy. We simply can’t guarantee consistent weight.” This situation is not uncommon in plastic molding, with each injection molding machine incurring tens of thousands of dollars in annual losses from resin, labor, and scrap. Even for medical device component injection molding plants, weight tolerances as small as ±0.1 grams pose a greater risk; a single batch of defective parts can result in six-figure losses.

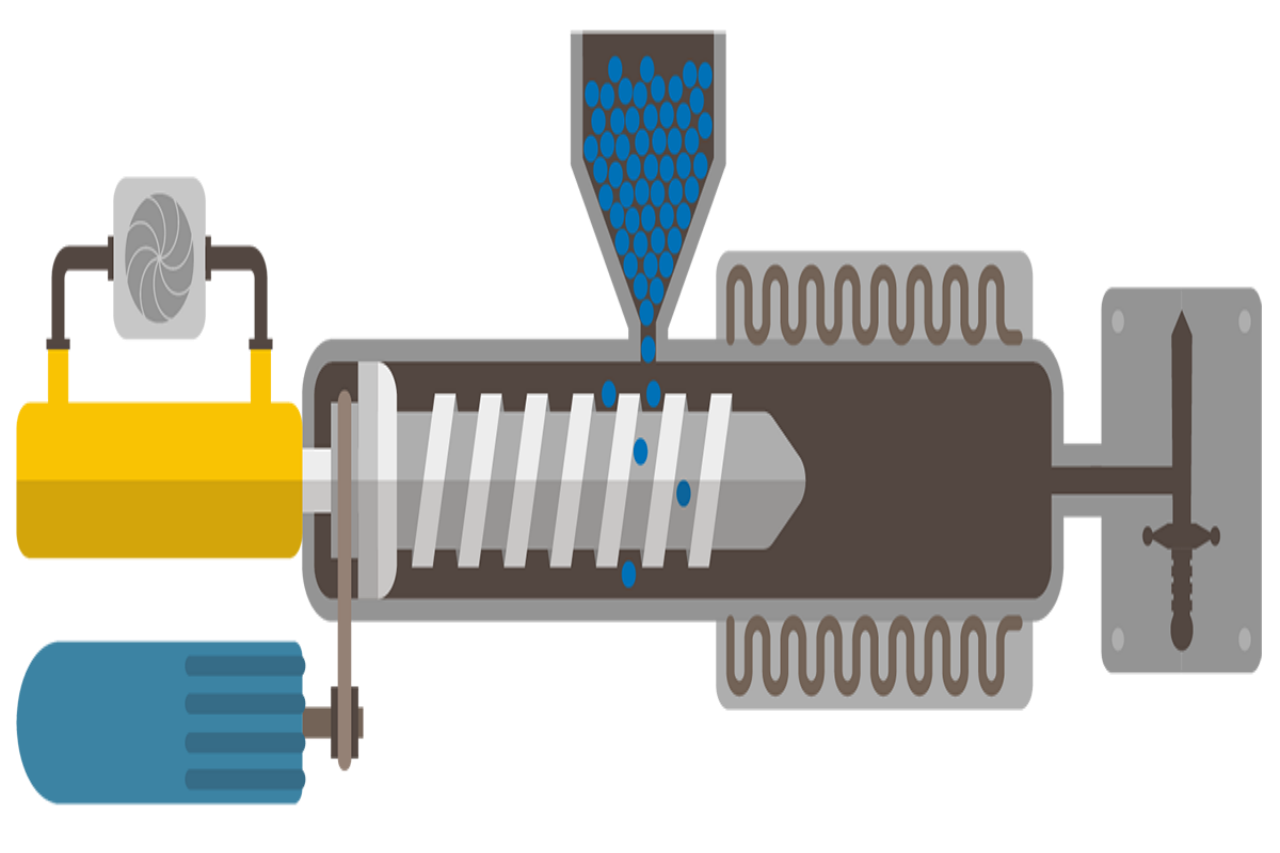

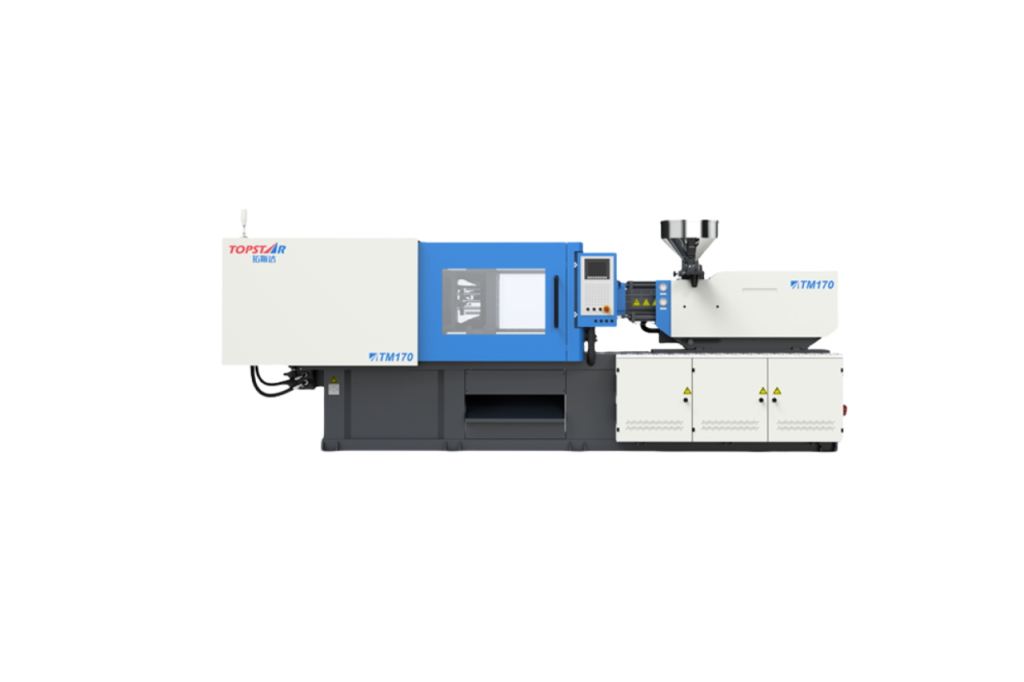

As an engineer at Topstar, I knew the root cause wasn’t an operational error; it was improper pressure control. To address this, Topstar uses low-damping injection units and linear guides in its plastic injection molding machines to achieve sensitive pressure detection and stable control.

What is weight deviation in plastic molding? How does improper pressure control lead to weight deviation?

To solve the weight deviation problem in plastic molding, it’s essential first to understand the definition of weight deviation and why pressure control is its primary driver. Weight deviation is the discrepancy between a part’s quality and its target specifications. Even a deviation of only 1-2% can render the part unusable in applications with strict tolerance requirements. Improper pressure control primarily causes weight deviation through three aspects:

- Injection pressure fluctuations: Insufficient pressure leads to inadequate mold filling, while excessive pressure results in overfilling. Even small, uncontrolled fluctuations in pressure within each cycle can cause inconsistent material filling.

- Holding pressure mismatch: Holding pressure is used to hold material within the mold during cooling. If the holding pressure is too low, the material will shrink; if it is too high, excessive material will be squeezed into the mold. Improper control leads to fluctuations in holding pressure within each cycle.

- Pressure response lag: Traditional injection molding machines adjust pressure too slowly when resin viscosity or mold temperature changes, resulting in a batch of parts with unacceptable weight, which is only addressed after the problem is discovered.

The Impact of Weight Deviation in Plastic Parts

Weight deviation not only causes scrap but also affects every stage of production. First, for customers with strict tolerance requirements, entire batches of products will be rejected if parts exceed weight specifications. One Topstar customer had 3,000 parts rejected due to a 2% weight deviation, resulting in losses of tens of thousands of dollars. Furthermore, while some overweight parts can be reworked, labor and time costs accumulate.

Poor pressure control leading to excessive pressure accelerates wear on the mold cavity and core, shortening mold life by 25% to 30%. Overweight parts waste resin; one customer calculated that they wasted 220 pounds of resin per month, resulting in annual losses of several thousand dollars. Improving pressure control can eliminate 80% of weight deviations. One manufacturer reduced weight-related losses by 92% after switching to Topstar injection molding machines.

Why can’t traditional pressure control solve the weight deviation problem?

Traditional plastic injection molding machines struggle with weight deviations because their pressure control systems are slow to respond, lack precision, or are susceptible to frictional errors. The main problems include: older machines use high-friction injection units, which delay pressure regulation. By the time the machine reacts to a pressure drop, multiple parts with incorrect weights have often already been produced. Uneven movement of the sliding guides also leads to an uneven pressure distribution during injection. Even slight jamming can cause pressure spikes.

Additionally, traditional sensors have a 5-10 millisecond delay, making it impossible to detect and correct pressure changes in real time during plastic molding. Furthermore, operators need to adjust pressure settings based on experience rather than data, leading to over-adjustment and creating new weight problems.

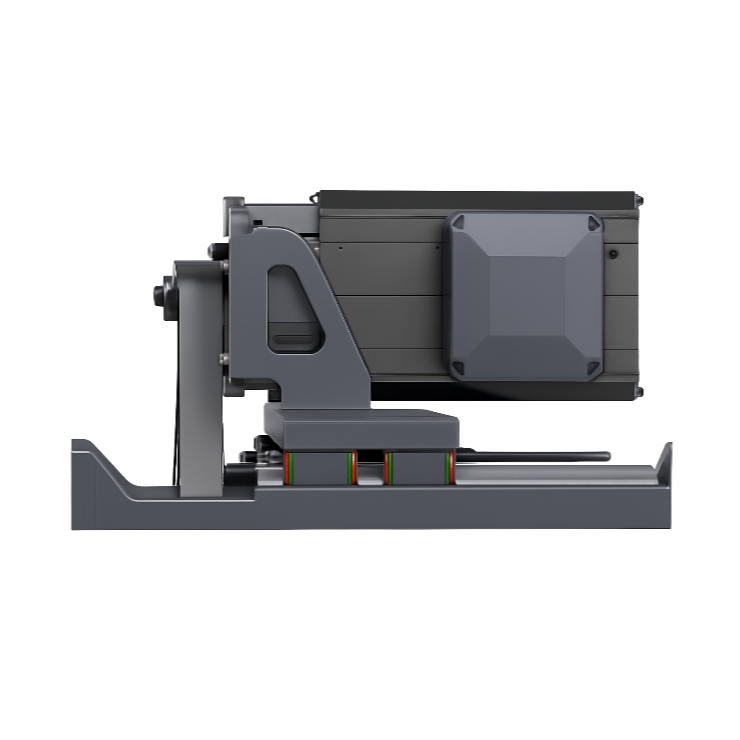

Using Low-Damping Injection Molding Machines and Linear Guides

Topstar solved the weight deviation problem by upgrading its plastic injection molding machines to enable precise, sensitive pressure control. The key lies in two technologies: low-damping injection units and linear guides. First, the low-damping injection unit minimizes friction in the injection mechanism, allowing pressure to be adjusted within 1-2 milliseconds—fast enough to correct deviations during injection. It responds instantly to changes in resin viscosity or temperature, ensuring consistent pressure from the first part to the last. Unlike sliding guides, linear guides allow the injection unit to move smoothly and without friction.

This ensures that pressure is evenly distributed across the mold, eliminating pressure spikes caused by jamming. Topstar equipment uses high-precision pressure sensors that can detect pressure variations as low as 0.1 MPa. The low-damping unit and linear guides elevate pressure control from sufficiently precise to truly precise, which is why Topstar injection molding machines can control weight deviation within ±0.3%.

How to optimize pressure settings for zero weight deviation in plastic molding?

Even with Topstar’s precise control, correct pressure settings remain key to eliminating weight deviation. First, review the material data. Check the resin manufacturer’s recommended injection and holding pressure ranges. For example, PP typically requires an injection pressure of 80–120 MPa, while ABS requires 100–150 MPa.

Then conduct small-batch testing in the plastic molding process: print 20–30 parts at the recommended pressure, then weigh them. If the part is light, increase the injection pressure by 5 MPa; if it is heavy, decrease it by 5 MPa. Simultaneously, fine-tune the holding pressure to 60%–80% of the injection pressure. If the part shrinks, increase the holding pressure by 3–5 MPa; if the part develops flash (becomes heavier), decrease the holding pressure. Then activate Topstar’s automatic compensation function, which adjusts the pressure based on real-time data from the pressure sensor. This eliminates deviations caused by changes in resin or mold temperature. Furthermore, it tracks weight data for each product batch. Topstar’s plastic injection molding machines record pressure and weight data, enabling you to identify trends and proactively adjust settings.

Achieve Zero Weight Deviation Through Precise Pressure Control

Weight deviations caused by improper pressure control don’t have to be a long-term problem in your plastic molding operations. The solution lies in using a responsive, precise pressure-controlled plastic injection molding machine. Topstar uses low-damping injection units, linear guides, and a sensitive pressure-detection system to control weight deviation to within ±0.3%. By eliminating friction, reducing pressure hysteresis, and enabling automatic adjustment, Topstar’s plastic injection molding machines transform unstable pressure into stable pressure, thereby reducing waste, defects, and costs.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/11/17

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/11/17

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/11/17

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/11/17

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar