How to Troubleshoot Weld Line Failures on Plastic Injection Moulding Machine?

2025/07/25 By Topstar

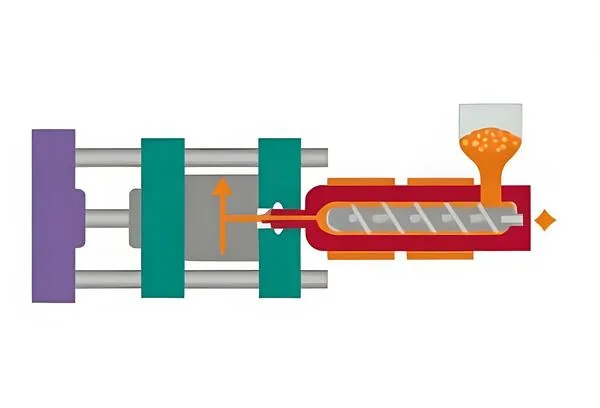

Weld line defects in injection moulding account for 25% of cosmetic and structural part failures and are the most common problem encountered by customers. Weld lines are formed when two melt fronts meet, and poor melt conditions can result in poor bonding or visible flaws. Troubleshooting this type of failure begins with determining the exact location and type of defect. In addition, record processing parameters, material grade, and mould temperature. By collecting detailed data in advance, you can lay the foundation for targeted corrective actions on the plastic injection moulding machine, reduce trial and error, and improve first-time pass rates.

Analyze plastic injection moulding machine material melt and temperature settings

The number one cause of plastic injection moulding machine weld line failure is often inconsistent melt temperature. If the melt temperature fluctuates by ±5°C around the set point, viscosity changes prevent the two flow fronts from merging properly. Therefore, the barrel area should be maintained within a tolerance of ±2°C. Active voice: I recommend using calibrated thermocouples in each barrel area and verifying the readings on a weekly basis. Additionally, verify that the melt temperature meets the resin manufacturer’s specifications. If the temperature is too low, the melt cannot flow. If the temperature is too high, the material will degrade and weaken the weld line. By stabilising the temperature of the injection moulding machine, you can improve melt uniformity and enhance weld line strength. Additionally, consider using a uniform screw design and regular barrel cleaning to maintain stable heat transfer and prevent degradation of high-performance engineering resins.

Optimize the injection speed and pressure curves of the plastic injection moulding machine

Injection speed and pressure also play an essential role in the formation of weld lines. First,ensuree the injection speed is sufficient to push the melt front together before cooling,typicallyy 50-80% of the maximum machine speed. Additionally, you must maintain the holding pressure for at least 3–5 seconds to compress the bonding area. By fine-tuning the injection curve to include a steep speed ramp and a subsequent pressure holding plateau. In addition, reduce the switching delay between speed and pressure control to prevent flow hesitation at the weld line. By optimising these curves on the plastic injection moulding machine, you can promote stronger fusion and minimise visible lines. Additionally, evaluate the shear rate to prevent polymer chain scission, and consider applying moderate back pressure during plasticization to enhance melt uniformity and mitigate molecular orientation imbalance at the weld line.

Improve mould design and gate location

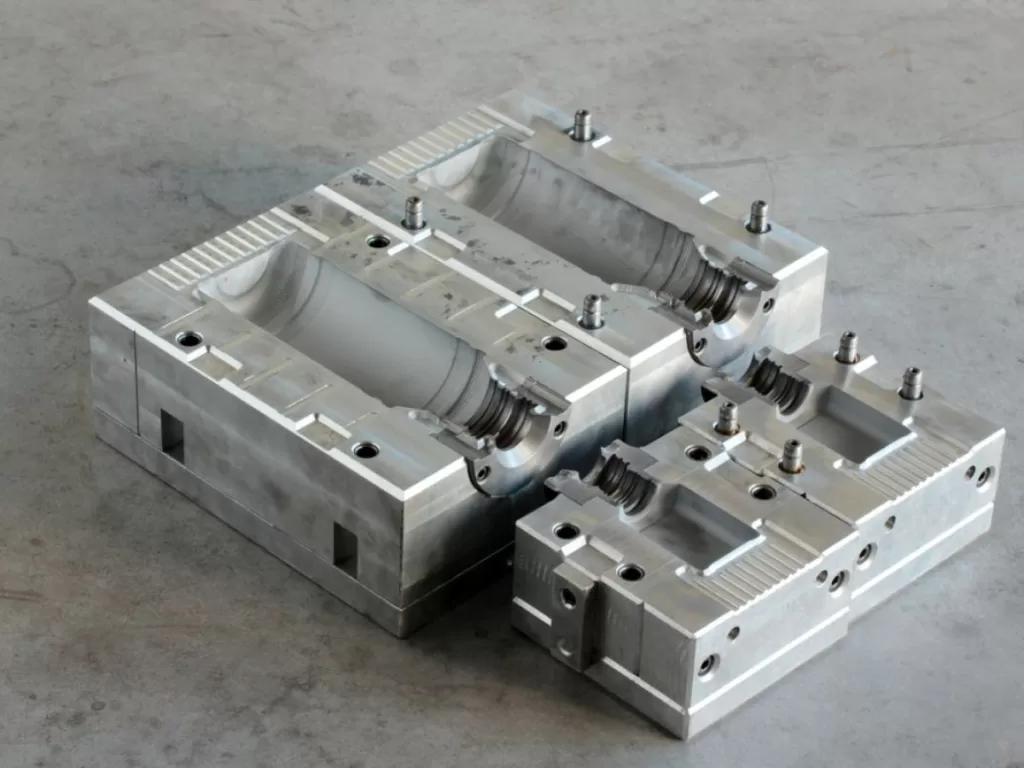

Mould design and gate location also have an impact on the quality of weld lines in plastic injection moulding machines. For example, you should position the gate so that the flow fronts intersect in an area that is not visible or structurally significant. This way, any small weld lines will not affect the part’s aesthetics or strength. Therefore, it is necessary to work with the mould designer to adjust the gate size and angle to ensure a balanced filling pattern. In addition, add flow guides or side gates to delay the convergence of the weld line front. Optimising the mould geometry and gate layout can minimise problematic weld lines and improve part integrity with your plastic injection moulding machine settings. Of course, you can use moulumoulsedmould simulation software to predict the weld location, optimise the geometry, and verify the venting location to eliminate air pockets that can cause line defects.

Ensure proper venting and cooling balance

Inadequate venting or uneven cooling can exacerbate weld line defects on plastic injection moulding machines. In addition to melt and pressure settings, confirm that the vent is unobstructed and provides a gap of at least 50 µm to allow trapped air to escape. Therefore, the formation of air pockets that hinder fusion can be prevented. You need to check the mould vents and add venting channels if necessary. Additionally, balance the cooling circuit to maintain a uniform mould temperature (±3 °C across the cavity) to prevent premature solidification of the flow front. Proper venting and cooling balance on the injection moulding machine ensures optimal melt convergence and strong weld lines. In addition, implement a regular mould maintenance program, including removing flash from the vent line and verifying coolant flow rates to maintain consistent thermal conditions during high-volume production.

Reduce the occurrence of weld line failures.

Troubleshooting weld line failures on plastic injection moulding machines requires stabilising melt temperature, optimising injection speed and pressure, optimising mould design and gating, improving venting and cooling, and monitoring the process. I recommend adjusting each parameter systematically and using real-time data to confirm the improvement. By applying these best practices, you will achieve stronger weld lines, more aesthetically pleasing parts, and higher overall production quality on the injection moulding machine.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/07/25

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/07/25

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/07/25

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/07/25

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar