Importance of Injection Moulding Machine Frame Rigidity

2025/06/16 By Topstar

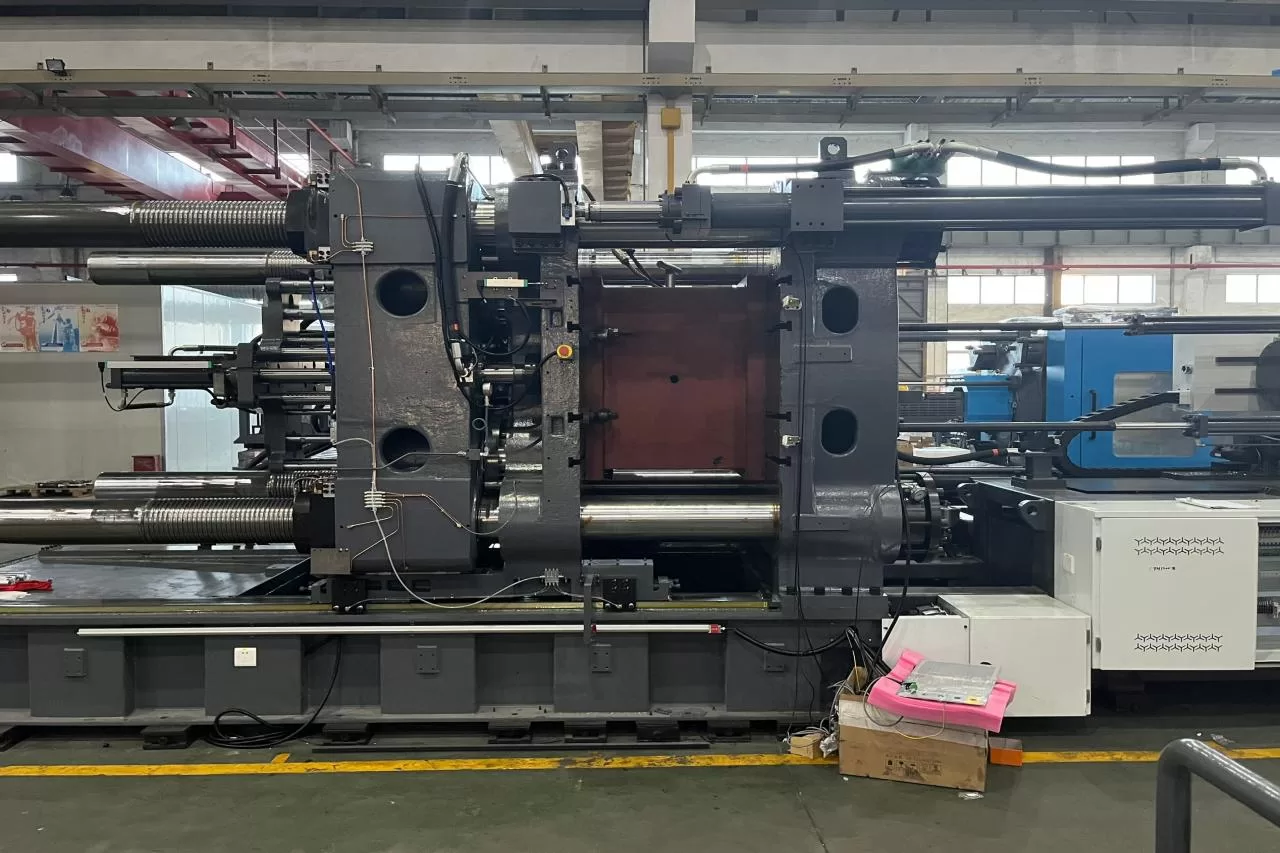

Frame rigidity refers to the ability of the machine’s structural frame to resist deformation under load. When the injection moulding machine applies high clamping and injection pressures, the frame must maintain its shape to ensure the mould is accurately aligned. Any slight deviation can result in flashing, under-injection, or uneven part filling. Additionally, a rigid frame in a plastic injection moulding machine reduces vibration during high-speed injection, thereby improving the surface finish and dimensional accuracy of the moulded parts. The rigidity of the injection moulding machine frame is necessary to ensure consistent cycle performance and part quality.

The effect of frame rigidity on injection moulding machine accuracy

A high-rigidity frame is directly related to the accuracy of injection moulding machines. During the clamping movement, any frame deflection under the clamping force will cause relative displacement between the two halves of the mould, resulting in mould misalignment and a flash on the parting line. Additionally, during injection, the screw barrel converts lateral force into an eccentric load, causing the melt front to progress unevenly. The high-rigidity frame can resist these forces and maintain the parallelism between the fixed platen and the moving platen. As a result, uniform cavity filling and tighter dimensional tolerances can be achieved.

During the manufacturing process, we utilise designs featuring wide support feet to provide stable and dynamic support. Make the mould opening and closing smooth to protect the mould and the machine better. At the same time, we also calibrate the tie rod preload to prestress the frame, ensuring that the operating force can offset the residual stress. Consistent calibration reduces wear on the mould surface, and the rigid frame minimises the need for frequent mould maintenance.

Enhance mould life through the rigidity of the injection moulding machine frame.

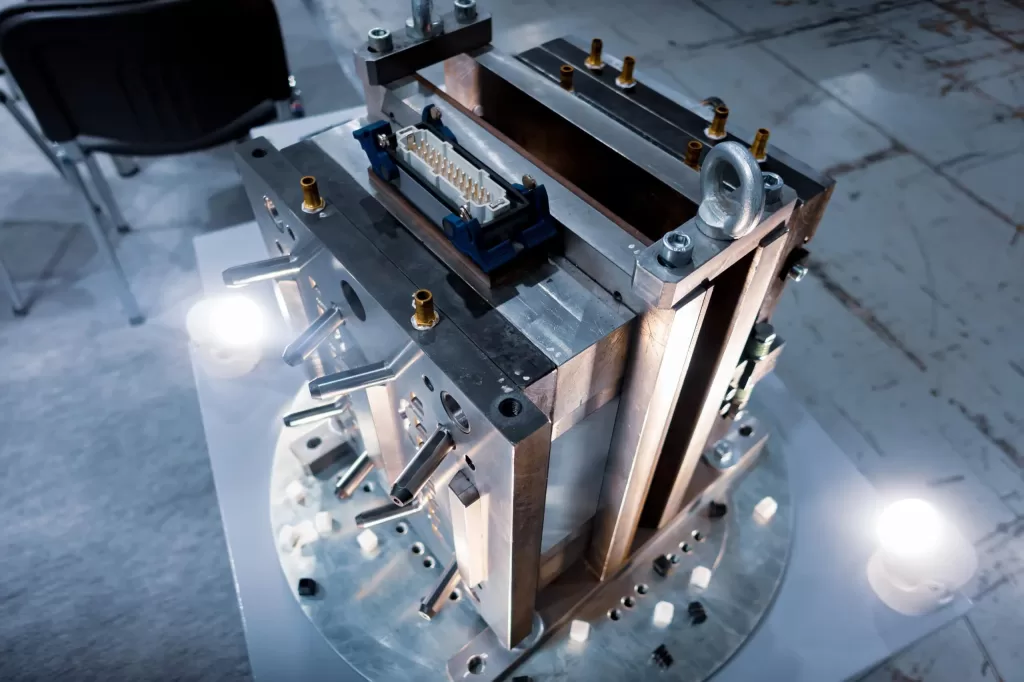

Mould costs account for a considerable portion of the total cost of injection moulding, and the rigidity of the frame also affects the mould’s lifespan. When the frame of a plastic injection moulding machine bends under high loads, the resulting misalignment applies uneven stress to mould components, such as cores, cavities, and ejection systems. When used for an extended period, it can cause premature wear, damage, and even breakage of the mould. On the other hand, a high-rigidity injection moulding machine frame can also evenly distribute the clamping force and injection force across the entire mould surface, thereby eliminating stress concentration.

In addition, the increase in frame rigidity can enhance thermal stability. Because the mould halves are in constant contact, heat transfer between the mould and the machine platen becomes more predictable, which reduces thermal cycling stresses in the mould steel. Therefore, when the frame stiffness is improved, the mould life can also be extended.

Role in high-speed plastic moulding machine operation

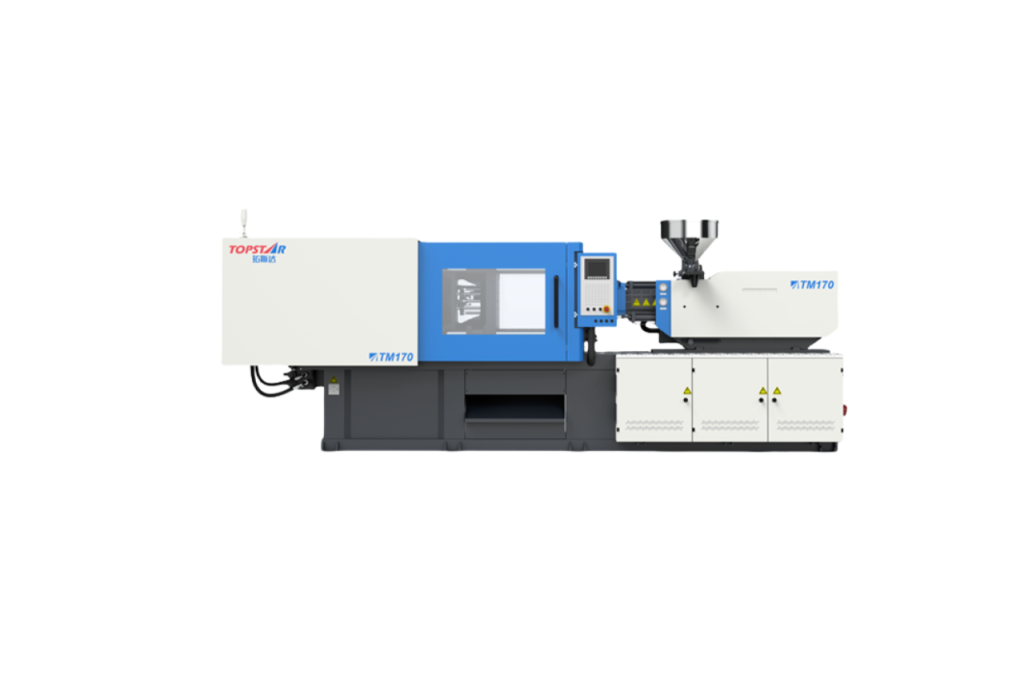

In injection moulding with high speeds and faster cycle times, the operation of high-speed plastic moulding machines pushes the frame stiffness to its limits. During high-speed injection, accelerations can exceed 5 m/s², and the resulting inertial forces tend to bend the frame, resulting in jet or flow marks on the part’s surface. Siemens’ research shows that frames exceeding a stiffness threshold reduce dynamic deflection, enabling operators to control cycle times below two seconds while maintaining part integrity.

Therefore, we will avoid resonance by combining the frame with external reinforcement and high-grade alloy steel while adjusting the acceleration curve to match the natural frequency of the frame. Of course, we will also equip the plastic moulding machine with real-time vibration sensors, allowing operators to detect frame bending anomalies early and adjust parameters dynamically. Operators adjust the frame stiffness to sustain high-speed injection moulding productivity.

Maintenance strategies to maintain frame rigidity

Technicians should regularly check and torque the anchor bolts during maintenance, as loose bolts may cause the machine to shift under load. You should also check tie rod preload annually—if measurements show tie rod slack outside the manufacturer’s tolerance, the tie rods should be retightened or replaced. Next, verify the integrity of the hydraulic manifold, as leaks or pressure loss can reduce the injection moulding machine’s clamping force, which can indirectly cause frame deformation.

Also, monitor the flatness and levelness of the machine floor—uneven support surfaces can cause uneven loading and accelerate frame fatigue. Some plants implement vibration analysis during planned downtime to detect early signs of frame microcracks or weld fatigue. Operators can perform such inspections quarterly and record the results in a centralised maintenance management system. Maintaining frame rigidity through systematic maintenance can safeguard machine accuracy.

Providing precise mold alignment and preventing part deviation

Injection moulding machine frame rigidity is fundamental to every aspect of moulding operations, from part accuracy and mould life to high-speed performance and long-term reliability. By choosing a machine with a highly rigid frame, you can ensure precise mould alignment, prevent costly deviations in part tolerances, and maintain rigidity by proactively checking the foundation and tie rods, thereby guaranteeing consistent cycle times even under the most demanding conditions.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/06/16

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/06/16

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/06/16

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/06/16

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar