Mastering the 160℃ mold temperature controller: Which materials require 160℃?

2025/11/12 By le zhan

Many injection molding plants fail to maintain a stable mold temperature of 160°C when producing high-temperature polymers, resulting in numerous scraps, rework, and mold damage. For example, a medical product manufacturer scrapped 1,200 PEEK components last year because its mold temperature was consistently maintained at 145°C—flow lines and warpage rendered these components unusable. Therefore, mastering 160°C mold temperature control is crucial for producing high-performance materials with specific properties. We will also inform you about the materials that require a 160°C mold temperature, their practical applications, and how Topstar’s 160°C mold temperature controller ensures accuracy.

160°C Mold Temperature Controller: Why 160°C is the “Optimal Temperature” for High-Temperature Materials

For materials with high melting points and poor flowability, a 160°C mold temperature solves three key challenges:

Good Flowability: High-temperature materials, such as PEEK or PSU, exhibit a viscous molten state. A 160°C mold temperature enables the material to maintain sufficient flowability, allowing it to fill thin walls, complex cavities, and tight tolerances, thereby avoiding short shots and flow marks.

Reduced internal stress: Rapid cooling of high-temperature polymers generates internal stress, leading to warping, cracking, or component embrittlement. At 160°C, the material cools more slowly, allowing it to crystallize or relax more evenly.

Mold release agent: Sticky, high-temperature materials can adhere to cold molds. At 160°C, friction is reduced, enabling the machine to demold parts cleanly and efficiently, which avoids damage and removes scrap from torn edges or deformed areas.

A plastics engineer at an automotive supplier explained, “For our PEEK sensors, 160°C is absolutely non-negotiable. Below this temperature, the scrap rate reaches 10%. At 160°C, the scrap rate drops to 0.8%—Topstar’s mold temperature controller locks the temperature within this range.”

Key materials that can be processed with a 160°C mold temperature controller

Not all plastics require a high temperature of 160°C; only high-performance polymers, designed for extreme environments (such as high temperatures, chemicals, and mechanical stress), do. The following four materials are common mold temperature controllers requiring 160°C:

PEEK: The most commonly used high-temperature polymer, used in medical implants, aerospace stents, and oil and gas components. Melting point is approximately 343°C; a mold temperature of 160°C ensures flowability and reduces stress.

PSU: An amorphous polymer used in food processing equipment, medical devices, and electrical insulators. The melting point is approximately 300°C; 160°C prevents component embrittlement and improves dimensional stability.

PEI, also known as “Ultem”: Used in aerospace interiors, automotive engine compartment components, and 3D printing consumables. The melting point is approximately 337°C; 160°C enhances its flowability in thin-walled parts.

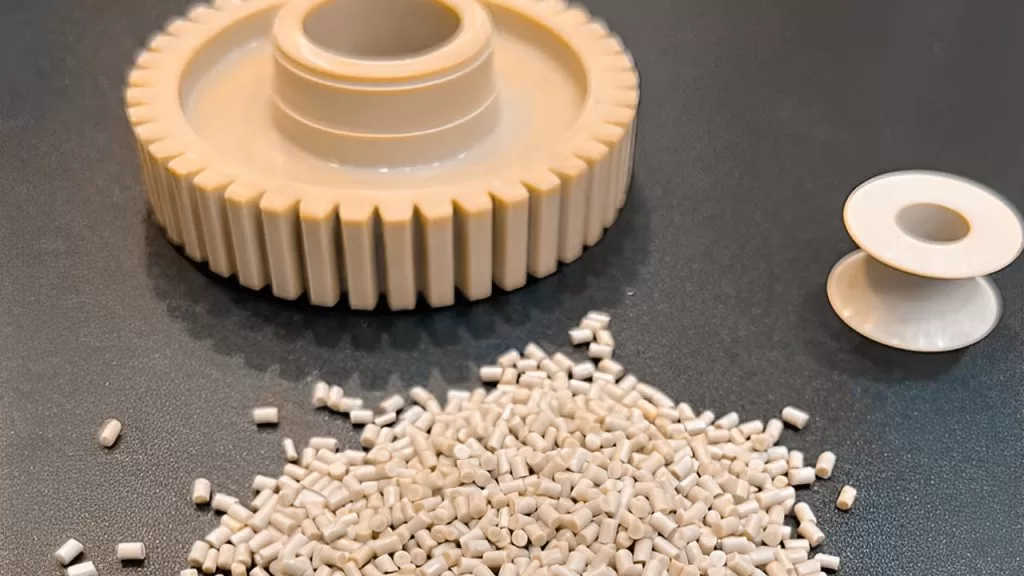

PA 46: A semi-crystalline nylon used in high-temperature gears, bearings, and connectors. The melting point is approximately 295°C; the operator uses a 160°C mold temperature controller to control crystallization for maximum strength and wear resistance.

Optimizing PEEK Material Processing

PEEK is the gold standard for high-temperature injection molding, and the manufacture of high-quality parts relies entirely on a 160°C mold temperature controller. Topstar’s 160°C mold temperature controller maintains an accuracy of ±0.5°C, which is crucial for PEEK material, as a 5°C temperature difference can cause flow lines. It also ensures uniform heat distribution, which is essential for PEEK parts that often have complex geometries. Topstar’s 160°C mold temperature controller utilizes a high-flow pump to evenly circulate heat transfer oil, ensuring that each cavity reaches 160°C without cold spots. It also supports a digital PID control system, enabling real-time temperature adjustments to prevent overheating and maintain optimal temperature. Mechanical Properties of PEEK. Ensuring proper mold temperature control prevents PEEK material degradation, yellowing, and embrittlement.

PSU/PEI – Processing Amorphous High-Temperature Polymers

PSU and PEI are amorphous polymers with properties different from PEEK, but they still require a 160°C mold temperature controller for optimal performance. Manufacturers commonly use PSU in FDA-approved food contact parts and medical device housings. A 160°C mold temperature controller prevents stress whitening, ensuring parts can withstand repeated steam sterilization. Manufacturers favor PEI for its flame retardancy and strength at 170°C. A 160°C mold allows PEI to flow into thin-walled molds for manufacturing electrical connectors and aerospace panels.

Topstar’s 160°C mold temperature controller, employing dual-zone heating technology, excels in this area and is ideal for molds with multiple cavities or complex cores. One electronics manufacturer utilizes it for PEI connectors, noting that “Dual-zone heating allows us to reach 160°C on both the core and cavity simultaneously.” Our connectors now fit perfectly, eliminating the need for rework. “

Designed explicitly for High-Temperature Materials

Topstar’s 160°C mold temperature controller is not a “standard” product, but instead explicitly designed for materials such as PEEK, PSU, PEI, and PA 46. Key features include:

Digital PID Control: Automatically adjusts heating power to maintain a temperature of 160°C, even during injection molding machine operation, despite temperature fluctuations. No manual adjustment is required; the system automatically operates once it is set.

High-Temperature Heat Transfer Oil Compatibility: Uses heat transfer oil rated at 300°C, ensuring stable heat transfer at 160°C without performance degradation.

Self-Diagnostic Alarms: Alerts operators to temperature deviations, pump malfunctions, or low oil levels—preventing scrap.

Small Footprint: Ideal for small factory spaces, this model features a user-friendly touchscreen that displays real-time mold temperature, cycle count, and maintenance alarms.

One OEM injection molding company tested three brands before choosing Topstar: “Topstar’s controller is the only one that can maintain a stable 160°C PEEK injection temperature 24/7.” Other brands exhibit temperature fluctuations of 8-10℃.

160℃ High-Temperature Processing for High-Quality, High-Value Parts

160℃ mold temperature controllers are ideal for high-temperature polymer processing. For materials such as PEEK, PSU, PEI, and PA 46, Topstar’s 160℃ mold temperature controllers are specifically designed to meet the unique needs of these materials. Their accuracy, reliability, and ease of use easily handle even the most complex production processes. If you are processing high-temperature materials, do not choose controllers prone to drift or failure; Topstar’s mold temperature controllers provide consistently stable results.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/11/12

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/11/12

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/11/12

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/11/12

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar