Molding Machine Buying Guide: Key Parameters for Precision Plastic Parts Production

2026/02/11 By le zhan

The manufacturing tolerance for errors in precision plastic parts is exceptionally low. Even a deviation of a few micrometers can lead to the scrapping of an entire batch of parts and unstable assembly. Unlike traditional product manufacturing and the production of other precision plastic parts, the requirements for dimensional tolerances, repeatability, and melt behavior stability are much higher here. Therefore, when evaluating a molding machine, manufacturers should not only focus on clamping tonnage and price, but also on performance parameters that directly affect process stability and part precision.

Technical Parameters of the Molding Machine Used for Producing Precision Plastic Parts

First, the precision and stability of the clamping system need to be evaluated. The clamping unit of the molding machine plays a decisive role in the dimensional consistency of the parts. Although many buyers focus only on the nominal clamping force, precision plastics require a more in-depth evaluation. First, the parallelism of the mold plate and the stiffness of the tie rod directly affect the mold’s alignment. A high-rigidity structure ensures that the clamping force is evenly distributed on the mold surface. Second, the clamping force must be matched with the projected area and material properties. Excessive clamping force in injection molding machines increases energy consumption and mold wear, while insufficient clamping force may lead to flash and dimensional instability. Therefore, accurate clamping force calculation based on cavity pressure is crucial. Compared to traditional hydraulic systems, injection molding machines with servo-driven clamping systems offer more stable holding pressure and better repeatability. Consequently, they significantly improve the consistency of precision parts production.

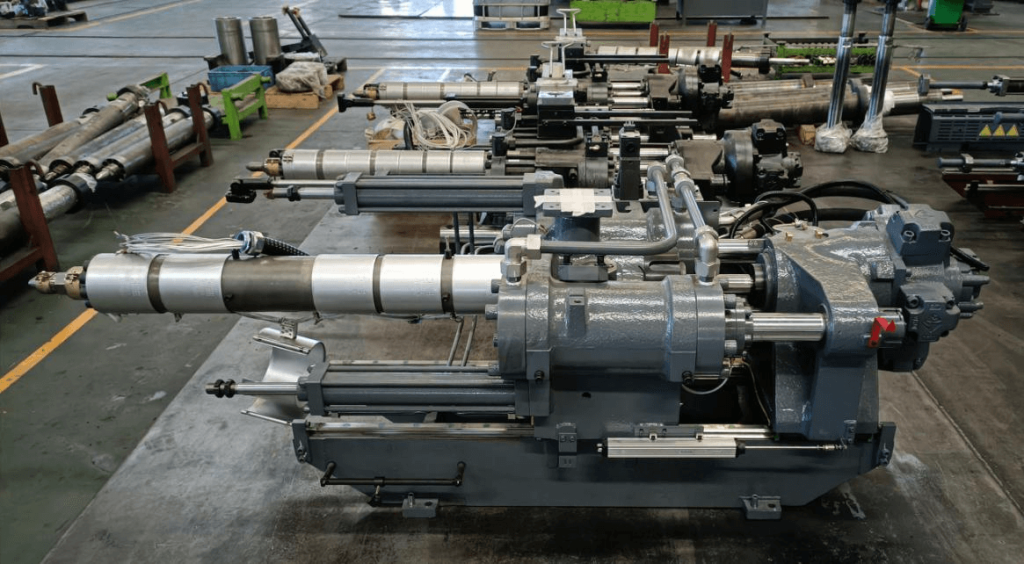

Injection Unit Performance of Molding Machine

The injection unit determines the accuracy of molten plastic filling the mold cavity. In precision manufacturing, injection speed control, pressure stability, and positional accuracy must be coordinated.

Injection molding machines for precision plastic parts should possess the following features:

- High-resolution injection position feedback

- Stable injection pressure control

- Precise V/P (speed-pressure) switching.

For thin-walled or micro-precision parts, rapid injection response capability is critical. Response delays can lead to insufficient injection volume or dimensional deviations. Advanced servo systems shorten response time and ensure consistent injection cycle performance. Furthermore, injection volume repeatability is also critical. For precision parts, even minute deviations in injection volume can affect the part’s weight and dimensional tolerances.

Plasticizing Capacity and Melt Uniformity

Precision molding does not begin with injection molding; it starts with plasticizing. A stable melt is essential to ensure dimensional stability and consistent mechanical properties. Therefore, the screw design of the molding machine should be matched to the material being processed. For engineering plastics such as PC, POM, PA, or LCP, the screw’s length-to-diameter ratio and compression ratio must ensure that the material melts fully without degradation.

Barrel temperature control accuracy is another critical parameter. Uniform melt temperature reduces internal stress and shrinkage differences. High-quality molding machines use precision temperature controllers and optimized heating zones to maintain consistent temperature control. Furthermore, stable back pressure during plasticizing improves material mixing and eliminates air trapping. When combined, these factors improve part accuracy and reduce defect rates.

Control System Accuracy

The control system is the brain of the entire injection molding production process. Even with excellent hardware performance, poor control accuracy will affect product quality. Therefore, you must ensure that the injection molding machine you purchase has real-time monitoring of injection position, pressure, and speed to achieve extremely high repeatability.

In addition, the advanced control system also enables:

- Multi-stage injection programming

- Precise holding pressure curves

- Real-time data monitoring

- Production traceability

Traceability is increasingly vital for manufacturers of precision plastic parts. It helps optimize production processes and conduct quality verification, especially in the automotive, medical, and electronics industries.

Molding Machine Performance and Selection Strategy

Energy efficiency and servo drive systems are paramount, as energy consumption significantly impacts long-term operating costs. Therefore, evaluating the injection molding machine’s drive system is crucial. Topstar’s all-electric injection molding machines offer higher precision and energy efficiency. The electric servo system reduces unnecessary motor operation and stabilizes oil temperature, minimizing communication latency during high-speed cycles. This real-time feedback loop optimizes position, speed, and pressure control for optimal performance. Simultaneously, the servo self-drive motor operates at very low and smooth speeds, eliminating product flow marks.

Structural Rigidity and Machine Frame Design

The frame structure of the molding machine determines vibration control and mechanical stability. A rigid frame reduces deformation during high-speed injection and clamping processes. Topstar’s all-electric injection molding machine series features a high-rigidity, low-friction mechanical structure that is well-suited for precision molding. This high-strength casting structure improves long-term stability and reduces deformation during continuous operation. Furthermore, the non-contact tie-rod design eliminates the need for lubrication, reducing contamination and stress on the molding die’s columns and linear guides.

Compatibility with Automation and Auxiliary Equipment

In today’s digital, AI-driven intelligent manufacturing environment, the manufacturing of precision plastic parts requires intelligent automation integration. Therefore, the selected injection molding machine must support seamless communication with injection robots and auxiliary systems.

Required injection molding auxiliary equipment includes:

- Drying and Dehumidifying System

- Automatic loading machine

- Mold Temperature Controller

- Injection molding robot

- Granulating and Recycling System

Topstar’s molding machine series all adopt an “integrated injection molding process machine” design, enabling communication among the central unit, auxiliary equipment, and the automation system via a self-developed control system. Its core lies in integrating the software system, allowing a single control interface to manage multiple devices and optimize the entire injection molding process, including raw material pretreatment, plasticizing, molding control, and part removal. Through system integration, the combination of main and auxiliary equipment, and the application of sensor technology, optimized control of precision injection molding elements such as temperature, speed, position, pressure, and time has been achieved. This significantly improves production efficiency and quality control, meeting customers’ comprehensive needs for production efficiency and management of precision plastic parts.

Achieving Precision Injection Molded Parts Manufacturing

In precision plastic parts manufacturing, equipment selection directly determines product consistency, operational stability, and long-term profitability. Choosing the right injection molding machine involves more than just looking at basic specifications. Manufacturers must carefully evaluate clamping accuracy, injection repeatability, plasticizing stability, control system accuracy, energy efficiency, and compatibility with peripheral auxiliary equipment. A well-matched injection molding machine not only ensures dimensional accuracy but also reduces scrap rates, stabilizes output, and lowers total operating costs.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/02/11

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/02/11

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/02/11

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/02/11

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar