Prevent flow stagnation and diffusion of low viscosity resins in plastic molding machine

2025/09/24 By le zhan

Low-viscosity resins enable thinner walls, faster filling rates, and finer details in the injection molding process. However, these rheological advantages also present persistent challenges, including flow stagnation, uncontrolled spreading, weld lines, and unpredictable cooling patterns. For plastic product manufacturers, these defects directly lead to scrap, rework, production losses, and customer returns. Therefore, preventing flow stagnation and spreading in low-viscosity resins during plastic molding machine operations is crucial.

Resin Rheology, Temperature Sensitivity, and Causes of Stagnation

Stagnation and uncontrolled spreading are rooted in fluid dynamics. Low-viscosity resins behave like low-resistance fluids, flowing readily under pressure but also responding rapidly to temperature gradients, shear history, and cooling of the mold surface. Stagnation also stems from viscosity and shear thinning. Low-viscosity materials still exhibit shear thinning. In practice, this means that high shear rates at gates and runners thin the material and accelerate flow. However, when flow slows in dead zones or near core pins, viscosity rebounds, leading to localized stagnation.

Furthermore, many low-viscosity resins have a narrow processing window due to temperature sensitivity and temperature gradients. Slight cooling at the gate or along thin ribs can increase local viscosity and promote premature solidification, leading to downstream material stagnation and weld line formation. Conversely, excessively high temperatures can reduce viscosity and increase diffusion and flash. For injection molding, it is essential to obtain rheological data for the resin from the supplier. For each candidate polymer, conduct short-term trials using conservative gate dimensions and moderate injection speeds, monitoring the pressure and screw recovery curves for early signs of stagnation.

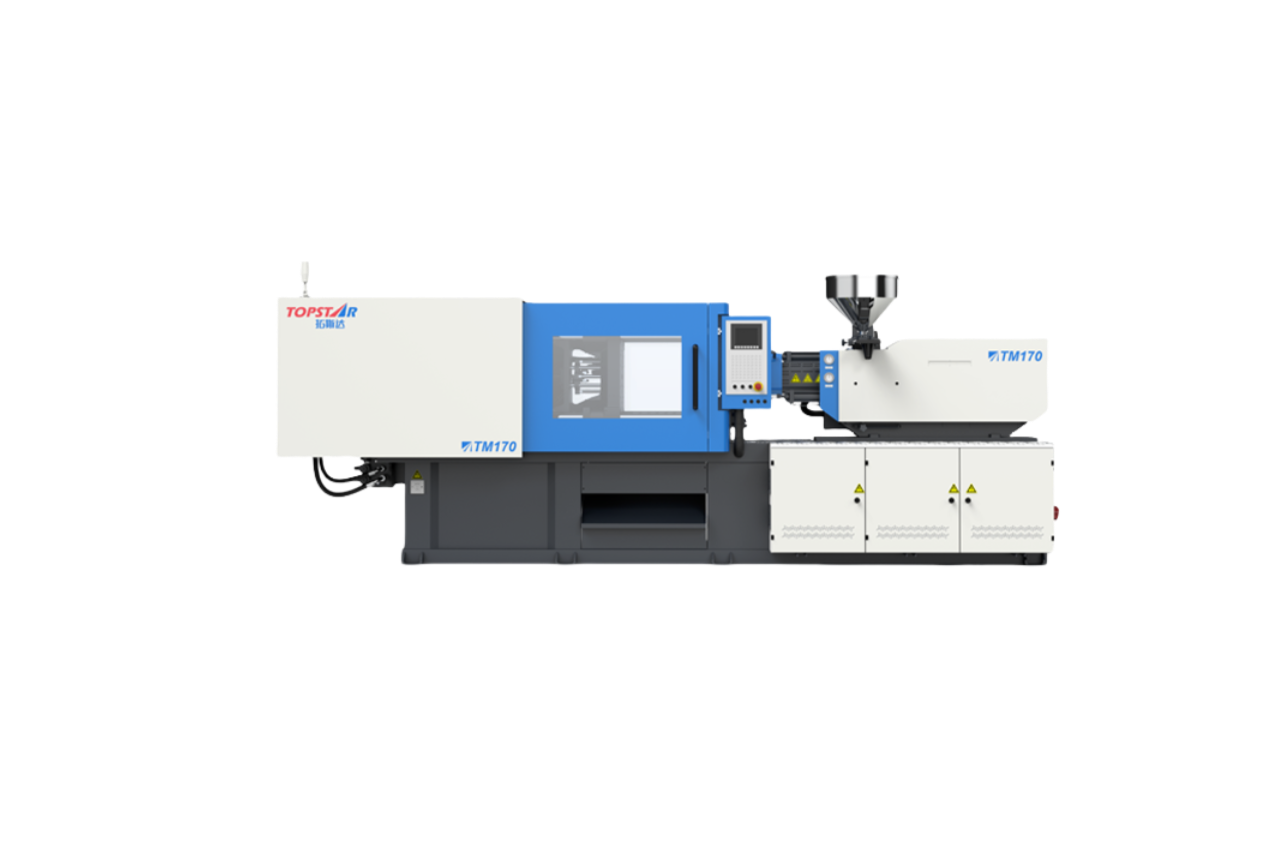

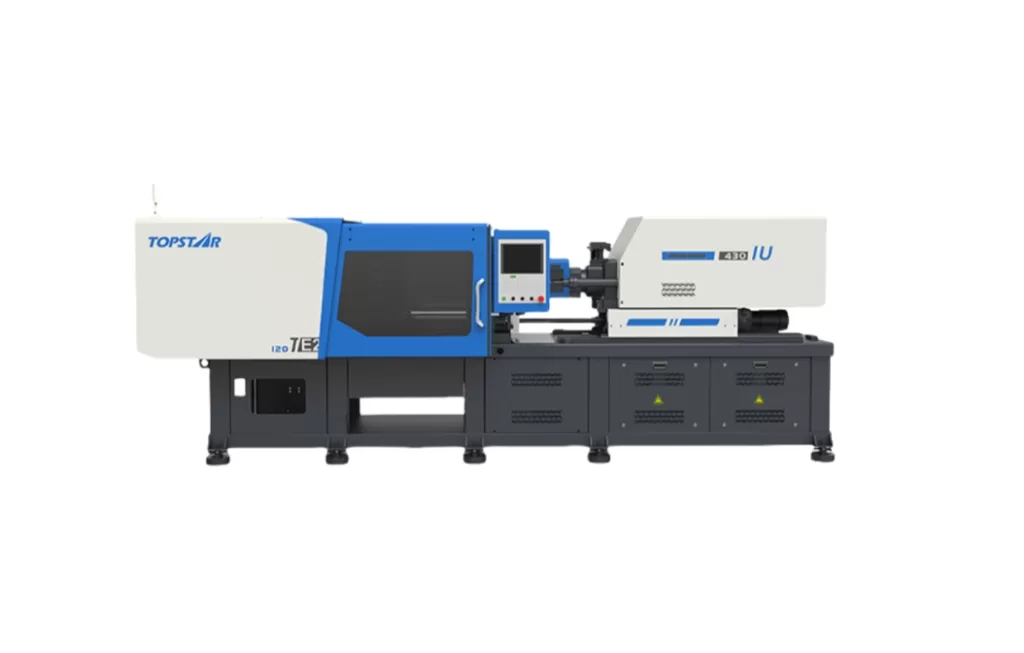

Plastic Molding Machine and Screw Selection

The injection unit is your first line of defense. A plastic molding machine designed for high-flow, low-viscosity materials must provide controlled shear, fast recovery, and microsecond pressure control. A suitable screw and drive system can shape the melt state for predictable and stagnation-free filling. For low-viscosity resins, a short aspect ratio, moderate compression ratio, and barrier or distributed mixing elements are recommended to ensure uniform melt temperature and avoid localized overheating. A barrier screw improves melt efficiency while still maintaining a controlled metering zone to prevent excessive thinning.

Additionally, it’s essential to select a plastic molding machine equipped with high-precision servo drive controls to precisely control injection speed and pressure. Topstar’s all electric injection molding machines offer a faster closed-loop response and tighter pressure control, reducing overshoot that can cause flash and the potential for late freeze-up, which can lead to stagnation. It’s also essential to use a thermally balanced nozzle with a small inner diameter that matches the shot size. This reduces dead volume and avoids cold spots that can cause droop. Hot tips or hot runner systems designed for low viscosities must maintain temperature control within a tolerance of ±1°C.

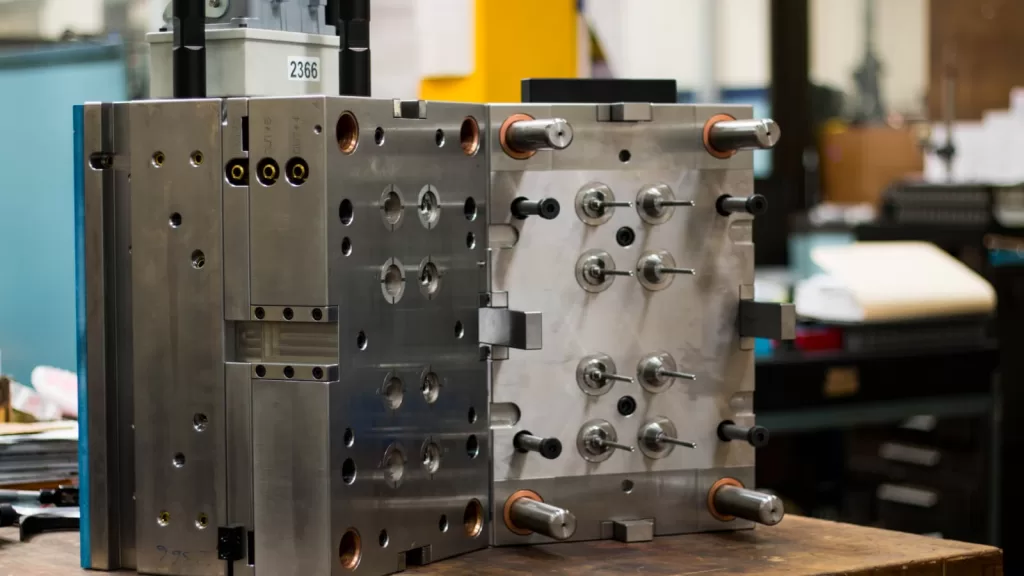

Avoid dead zones and adjust the gate geometry of the plastic molding machine.

Mold design determines whether the fluid will stagnate within the cavity. For low-viscosity resins, precise gating, runner balancing, and venting are crucial. The goal is to maintain velocity and eliminate areas where the fluid could unexpectedly decelerate and cool. Therefore, it’s essential to use edge gates or tunnel gates and carefully calculate the gate length to prevent premature freeze-up. At the same time, a wedge-shaped gate with a gradually decreasing cross-sectional area helps maintain gate flow. For thin-walled or long runners, a larger gate cross-section is preferred in individual cavities; however, this can be compensated for by slightly reducing the injection speed to avoid flash. For microfeatures or areas where aesthetics are crucial, the shortest path gate remains essential; use automatic shear control to minimize surface defects.

Additionally, runners should minimize their dead legs. For multi-cavity molds, runner designs should be as short and symmetrical as possible. Flow balancing should avoid excessively long runners or complex, long-arm hot runner manifolds unless the manifold features active temperature control and is optimized for resin viscosity. For hot runners, ensure the manifold channel diameter is appropriately sized to maintain low residence time and stable flow.

Adopt advanced strategies for process control and stable flow.

Even with well-designed molds and machines, process control can hinder stable production and increase yield fluctuations. Low-viscosity resins require both preventative and reactive control: predicting behavior and reacting within milliseconds to changing conditions. This can be achieved by installing piezoelectric or strain gauge cavity pressure sensors at critical locations. Use pressure-based control for speed-pressure switching instead of fixed-position control. This ensures the plastic molding machine adapts to actual cavity conditions, preventing switching too early, which can cause stalling, or too late, which can cause flashing.

Also, replace blunt step acceleration profiles with smooth S-shaped acceleration profiles to reduce inertial transients and minimize local shear peaks that can alter viscosity. Furthermore, real-time melt temperature monitoring enables the detection of screw and nozzle melt temperature variations, allowing for smooth filling or preventing front-end freeze. Use online melt temperature sensors and integrate them into the mold run sequence. Dynamically adjust barrel zone setpoints based on melt temperature feedback, and configure dwell and recovery times to avoid hot spots. Furthermore, monitor injection volume and screw cushion changes during each cycle of the plastic molding machine. Increased injection volume or cushion deviations may indicate drooling, degraded check valve performance, or inconsistent melt—all precursors to stalling and flashing.

Maintain optimal performance through regular maintenance and the use of auxiliary systems

Continuous prevention of stalling depends on operational discipline and the auxiliary systems running alongside the plastic molding machine. Minor oversights, such as worn check valves, dirty screens, or clogged vents, can cause a rapid reaction to low-viscosity resins. In injection molding, keep raw materials dry and clean. Install a high-efficiency hopper dryer, tightly control the dew point, and use an inline melt filter or screen appropriate for the resin and flow rate. Contaminants or moisture can significantly alter viscosity, causing blockages and diffusion abnormalities.

Also, regularly inspect nozzles for fouling and hot runner manifolds for deposits on runners. Low-viscosity resins can leave behind thin films that polymerize when exposed to heat. Check valves should be replaced regularly. Valve leakage and backflow can cause fluctuations in shot size and potentially create cold lumps, leading to stagnation. Ensure valve bodies have low dead volume geometry and are compatible with the resin’s thermal properties.

Eliminating Stagnation and Controlling Diffusion

Preventing stagnant flow and uncontrolled diffusion of low-viscosity resins in plastic molding machines is a complex issue. It requires selecting the appropriate screw geometry and a responsive injection unit for the plastic molding machine, as well as designing a mold with short, balanced runners, effective gates, and vents. Furthermore, real-time sensors and adaptive controls are utilized to manage the injection profile, ensuring performance is maintained through rigorous maintenance, effective material handling, and strict operator discipline.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/09/24

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/09/24

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/09/24

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/09/24

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar