Solve the communication delay problem of all electric injection molding machine

2025/09/19 By le zhan

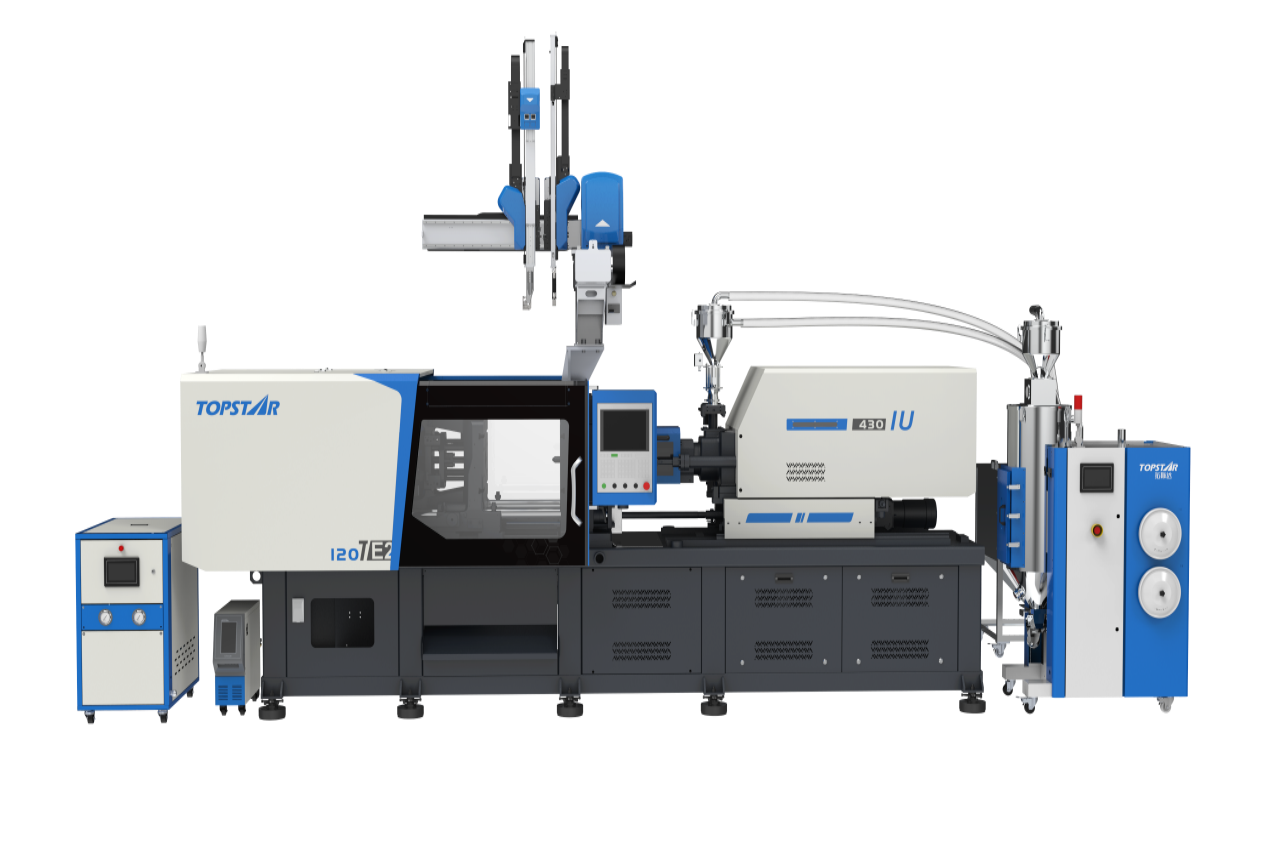

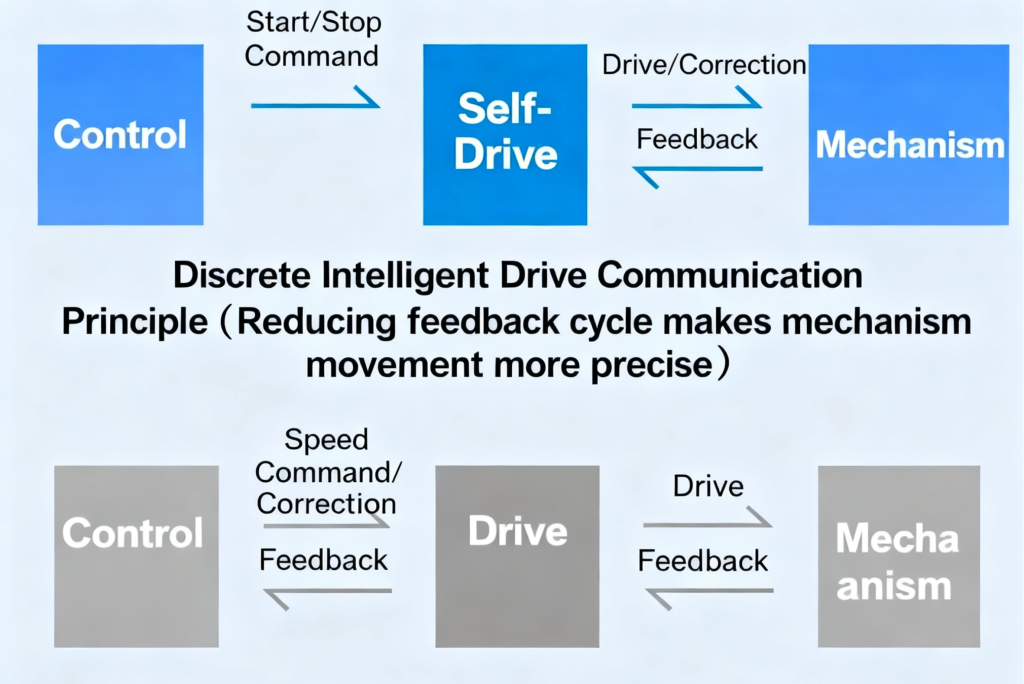

Communication delays between the host controller and servo drives are a common problem in injection molding. In all-electric injection molding machines, even a few milliseconds of delay can translate into measurable errors in position, velocity, and pressure at high cycle rates. Topstar’s TE II all electric injection molding machine embeds process intelligence in the servo drive, enabling the drive to locally generate and execute motor motion profiles. This patented control principle reduces reliance on periodic communication and mitigates the negative impact of network latency. The result is real-time, high-fidelity motor control, delivering 8-16 times faster response times in real-world production scenarios.

Communication Latency Issues Faced by All Electric Injection Molding Machine

All electric injection molding machines rely on fast, deterministic control of multiple servo axes, as well as rapid closed-loop pressure and position feedback. Traditionally, the host controller calculates motion profiles and transmits speed or torque setpoints to the servo drive at each cycle step. We emphasize that you should calibrate the clamping force during a trial run and regularly check it during mass production. This has two practical consequences:

1. Delayed response: By the time the drive receives a new velocity command, the motor and inertia have already exceeded the intended control point, causing overshoot or lag in position and pressure control.

2. Jitter and instability: Variations in data arrival time lead to inconsistent setpoint updates, which the drive must filter. Filtering introduces phase lag, reduces closed-loop bandwidth, and consequently slows effective response and degrades transient control performance.

In production, these control effects manifest themselves as increased cycle-to-cycle variability, more frequent short-cuts or flash, and reduced first-pass yields. Consequently, this problem becomes more severe as cycle times decrease and servo drives must cope with non-negligible control commands at high accelerations.

What is Topstar’s control approach?

Topstar fundamentally addresses this problem in its TE II all electric injection molding machine. Time-critical decision-making logic is moved from the host computer to the drive. Process parameters are sent to the servo drive via the host computer; the servo drive then locally generates the motor operating profile and autonomously executes it during each reciprocating cycle. The specific workflow is as follows:

1. Parameter Transfer Upon Setup or Recipe Change: The HMI or host controller sends molding process data to the servo drive each time a setup or recipe changes. The system sends data packets over the control bus but does not need to refresh them every millisecond.

2. Internal Latch and Profile Generation: The servo drive stores these parameters in internal latches.

3. Local Loop Execution: During each reciprocating cycle, the drive generates the required setpoints in real time based on the stored profile and executes them using its local, high-bandwidth motor control loop.

4. State Synchronization: The drive periodically sends synchronization packets containing condensed injection status information to the injection molding machine. This keeps the host informed without increasing the real-time control burden.

This architecture significantly reduces the reliance on deterministic motor-to-drive messaging during high-speed transients. Because the servo loop executes within the drive’s own processor and motor controller, response latency is limited by local processing and analog-to-digital conversion latencies, rather than millisecond network latency.

Improving Position, Velocity, and Pressure Control in All-Electric Injection Molding Machines

Offloading execution to the drive directly improves three measurable performance dimensions: position accuracy, velocity tracking, and pressure control. While the drive locally executes precalculated position-time trajectories, it performs high-frequency interpolation and uses direct encoder feedback within a tight control loop. This eliminates host communication latency in the inner loop, enabling repeatability of less than 0.01 mm in TE II electric injection molding machines. In contrast, host-centric architectures with lower frequency setpoints typically exhibit larger tracking errors during steep ramps.

Concurrently, in injection molding, pressure control during the packing process requires a rapid response to slight pressure deviations. This is achieved by embedding the pressure setpoint into the servo curve and using local feedforward and adaptive gains to track the force or pressure setpoint. This produces a smoother packing curve and faster correction of cavity pressure disturbances, minimizing sink marks and improving dimensional stability. Furthermore, the servo drive can run the inner velocity loop at frequencies of tens of kHz. With local curve execution, the adequate closed-loop bandwidth approaches the native performance of the drive. Compared to comparable electric injection molding machines, the measured response speed is 8 to 16 times faster.

Example in Thin-Wall and High-Speed Injection Molding

Example 1 – Thin-Wall Consumer Packaging (High Acceleration, Short Fill):

Baseline: 10-second cycle, 0.8-second injection-fill at high acceleration, with critical switching time within ±2 milliseconds. Communication jitter of 5-10 milliseconds causes inconsistent switching and varying holding pressures, resulting in a 2% short shot rate.

TE II test results: The host computer uploads the injection profile parameters, and the drive generates and executes the micro-timing locally. Measured switching jitter is reduced to <0.5 ms, the short shot rate is reduced to 0.3%, and cycle stability improves net uptime.

Example 2 – Multi-Stage Overmolding with Rapid Platen Motion:

Baseline: Multi-shot sequences require time coordination between the injection molding machine and the molding robot. Distributed control loops using networked commands can cause phase drift within the cycle, requiring operator intervention and slowing the cycle time.

TE II Results: Each actuator stores phase parameters and synchronizes them via a lightweight, cyclical synchronization token, which the actuator uses to trigger its local segment. Phase drift is reduced to negligible, robot handover times become deterministic, throughput increases by 6-10%, and scrap due to misalignment is reduced.

Real-time control at critical locations reduces the risk of communication delays.

Communication delays are not an unsolvable problem. Topstar mitigates the negative impact of network latency and jitter by offloading time-critical trajectory execution to the servo drives while retaining centralized recipe management. This approach has yielded tangible benefits for plastics manufacturers in India, the US, and other regions, including faster response times (reported improvements range from 8-16 times), tighter position and pressure control, reduced scrap, and higher production yields.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/09/19

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/09/19

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/09/19

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/09/19

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar