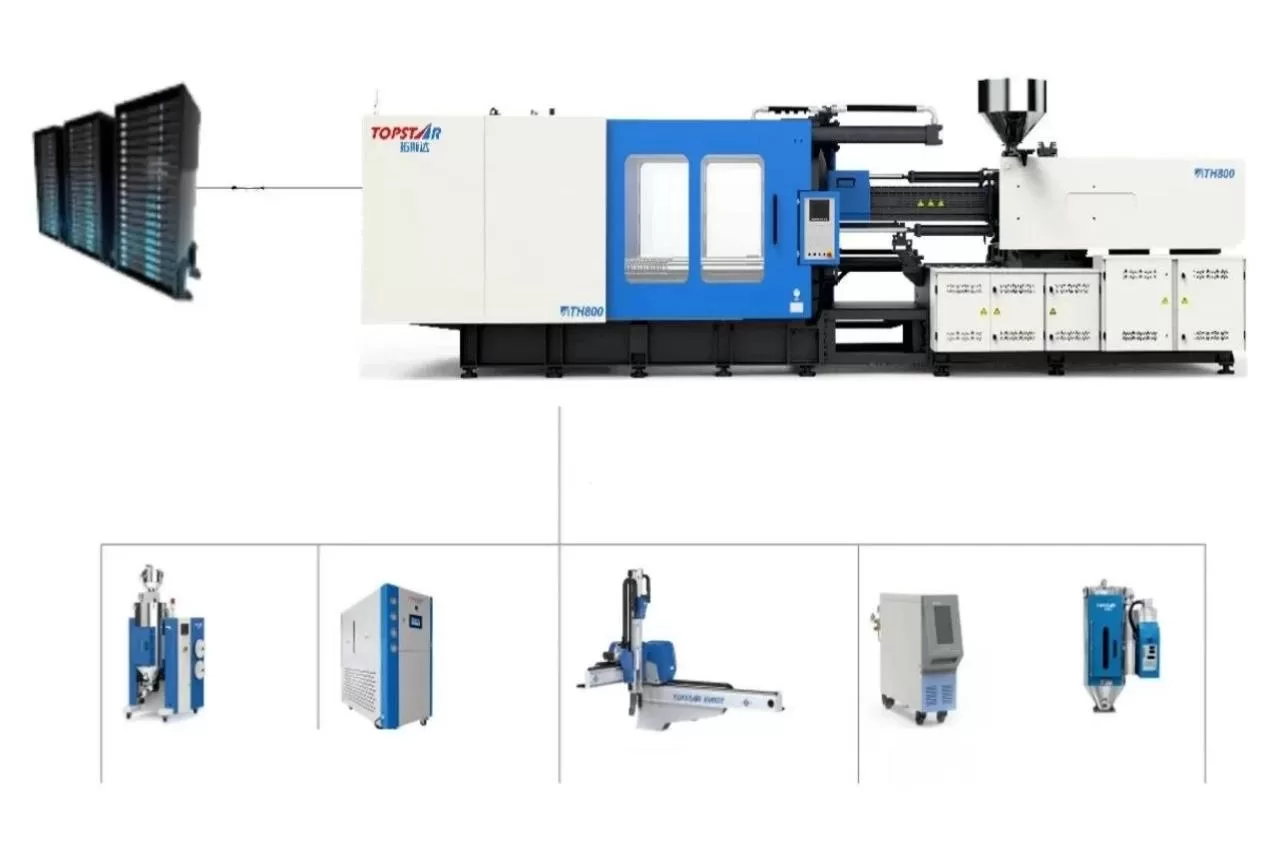

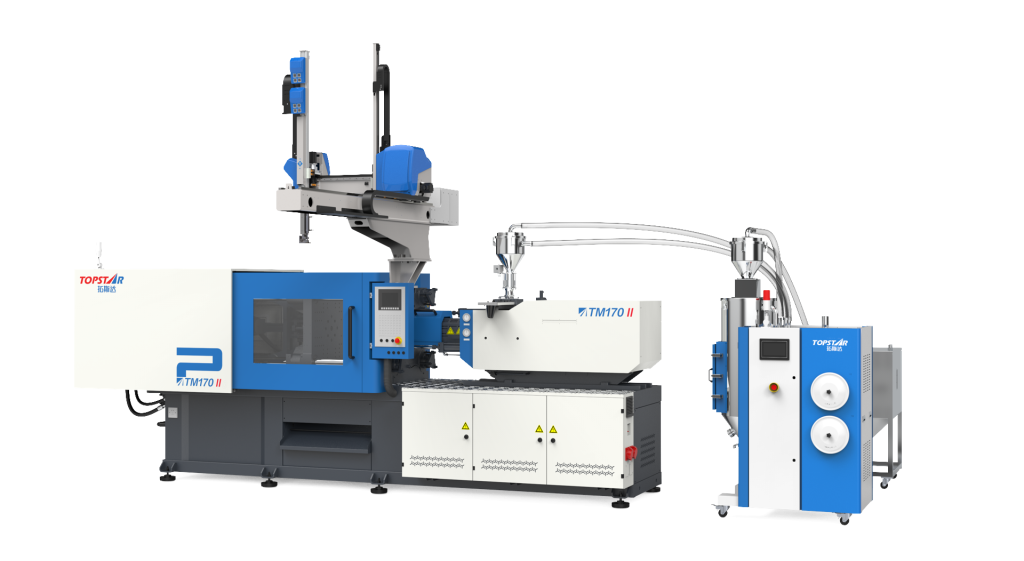

System compatibility: Topstar injection molding auxiliary equipment offers high integration for improved efficienc

2026/01/28 By le zhan

In today’s injection molding production, efficiency no longer depends solely on the injection molding machine itself, but rather on the coordinated operation of the entire production system. From material handling and drying to temperature control and automation, injection molding auxiliary equipment plays a crucial role in determining productivity, product consistency, and operating costs. However, many manufacturers still face challenges, including system fragmentation, complex interfaces, and poor data visibility between injection molding machines and auxiliary equipment. This is where the value of Topstar’s injection molding auxiliary equipment solutions lies. By designing auxiliary equipment that seamlessly connects with injection molding machines under a unified control architecture and using a unified control language, manufacturers can simplify operations, reduce downtime, and achieve higher overall efficiency throughout the entire injection molding process.

Integrated Control and Operational Visualization of Injection Molding Auxiliary Equipment

Topstar’s design places the injection molding machine at the center of a digital control ecosystem. In this integrated control model, key injection molding auxiliary equipment is not merely “connected,” but operates collaboratively. Integration begins at the hardware and protocol levels. It extends to the operator interface, allowing machine operators to view dryer dew point, chiller outlet temperature, loader status, and mold temperature stability via the injection molding machine’s HMI. This visualisation reduces the need for operators to switch between systems: they can diagnose slow cycles or quality fluctuations without walking between control cabinets or switching between multiple screens.

The advantage is that when the hopper dryer shows an increased dew point on the machine screen, the operator can pause production and clear the material before defects occur. When the mold temperature controller shows slow temperature recovery after demolding, the operator can adjust the cooling time without guesswork. Topstar uses standard industrial protocols—Modbus/RTU or TCP, CAN, and proprietary secure channels—to build a deterministic, low-latency control bus. Most importantly, this integration maps equipment data to machine-level recipes: temperature setpoints, regeneration cycles, and feeding speeds all become part of the mold recipe, so the corresponding auxiliary equipment settings are automatically recalled when changing molds. This ultimately reduces human error, speeds up mold changes, and improves part consistency.

Communication Protocols and Interoperability

To enable seamless integration of injection molding auxiliary equipment, choosing the proper communication standards is crucial. Topstar employs a layered approach: using reliable fieldbuses for fast control, standardized industrial protocols for interoperability, and secure IT-level connectivity for data analytics and cloud services.

At the field level, Topstar supports deterministic links, such as CAN bus for critical safety-related messages, and RS-485/Modbus for device telemetry. These protocols offer good noise immunity and are easy to use to build multi-device networks. For higher-level coordination and factory integration, Topstar utilizes Modbus TCP, OPC UA, and MQTT protocols, enabling auxiliary equipment to transmit data to SCADA, MES, or enterprise data lakes. Furthermore, to improve practical interoperability, Topstar provides pre-configured device profiles and standardized data models so that cooler temperatures, dryer dew points, and automatic loader status can be clearly mapped to the injection molding machine’s recipes and reporting systems. This reduces the need for custom wiring and programming during installation, thereby speeding up commissioning.

Driving Operations and Changeover Efficiency of Injection Molding Auxiliary Equipment

One of the most direct production efficiency improvements from integrated injection moulding auxiliary equipment is that users can adjust settings, including injection curves, holding pressure, as well as dryer dew point, hopper temperature, coolant setpoints, feeding speed, and mould temperature controllers, from a unified control interface. Topstar’s system centrally stores recipes and synchronizes them between the injection molding machine and auxiliary equipment.

Importance: Mold changes are no longer a series of manual adjustments; they are now a deterministic event. When the operator selects a mold program, the machine’s HMI triggers the auxiliary equipment to switch to the correct operating state—the dryer switches to the target dew point, the cooler heats up to the set temperature, the loader switches to the proper material line, and the mold temperature controller executes the preheating program. This coordinated operation reduces manual steps, minimizes preheating waste, and significantly shortens production time.

Energy Efficiency and Process Optimization

Through an integrated system, Topstar can coordinate auxiliary equipment and the injection molding machine to reduce energy consumption across the entire production unit. When equipment operates independently, unnecessary energy consumption peaks can occur: for example, the chiller runs at full capacity even when cooling demand is low; fans run continuously; and dryers regenerate according to a fixed timer instead of based on actual needs. Topstar’s integrated solution for injection molding auxiliary equipment implements an adaptive, on-demand control strategy, saving energy without compromising product quality.

For example, the chiller and mold temperature controller negotiate based on the heat load: during steady-state operation with stable mold temperature, the chiller reduces compressor capacity, allowing the thermal mass to handle transient loads. Conversely, during high-intensity, high-cycle production, the chiller actively increases its operating capacity. Similarly, Topstar’s hopper dryer switches from time-based regeneration cycles to dew point-based cycles. Instead of consuming regeneration energy on a fixed schedule, the system monitors the desiccant’s condition and only regenerates when the dew point reaches the required level. Beyond energy savings, process optimization also shortens cycle times through coordinated operation. For example, a faster mould temperature recovery strategy is achieved by coordinating the mould temperature controller with the injection moulding machine’s cycle scheduling.

High Reliability, Reduced Downtime

Topstar’s integrated solution makes maintenance of injection molding auxiliary equipment more innovative, shifting from reactive repairs to predictive and condition-monitoring maintenance, thus minimizing downtime. The integration generates a rich data stream: temperature, pressure, flow rate, motor current, vibration, and alarm history are all transmitted locally. This allows users to detect early signs of failure—such as a slight increase in chiller compressor current, gradually increasing dryer fan vibration, or a gradual drift in the mold temperature control loop.

Furthermore, a centralized dashboard aggregates auxiliary equipment and injection molding machine metrics into health scores and OEE calculations. Maintenance teams can prioritise work orders by urgency, avoid unnecessary preventive maintenance, and maintain a sufficient spare parts inventory based on actual consumption patterns. The integrated functionality also supports rapid fault isolation. When a part quality alarm occurs, engineers can replay relevant auxiliary parameters to find the root cause, reducing downtime.

Highly Integrated, Convenient, and Efficient Operation

Topstar’s integrated solution for injection molding auxiliary equipment bridges the gap between injection molding machines and auxiliary equipment, consolidating disparate equipment into a coordinated production platform. Topstar prioritizes secure and reliable communication, recipe management, energy-saving control, and predictive maintenance, helping manufacturers achieve higher throughput, better quality, and lower operating costs while simplifying daily operations for plant teams.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/01/28

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/01/28

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/01/28

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/01/28

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar