What improvements can all electric injection molding machine bring to thin-walled parts?

2025/08/15 By le zhan

All electric injection molding machines replace hydraulic drives with servo-driven motors, fundamentally changing how the machine controls position, speed, pressure, and timing. For thin-walled parts, these control advantages translate into fewer short shots, a more uniform appearance, tighter dimensional tolerances, and higher production yields.

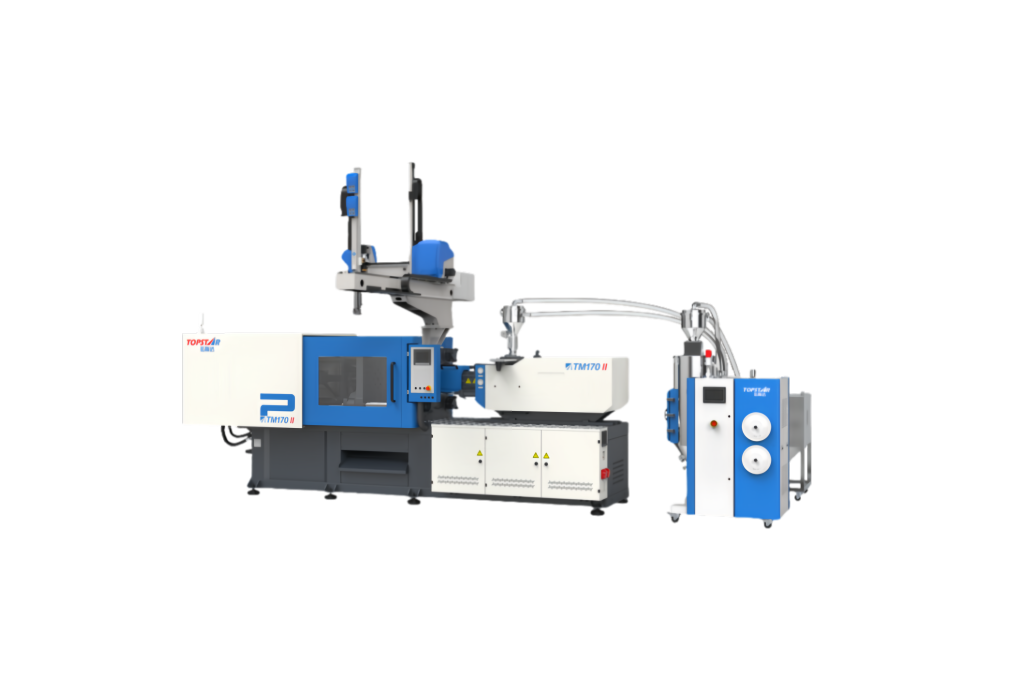

Specifically, Topstar’s all electric injection molding machines offer improvements in five practical dimensions: higher positioning and pressure accuracy; faster, repeatable injection and holding pressure profiles; greater energy efficiency and stability; cleaner operation and lower maintenance costs; and enhanced process monitoring and integration to ensure quality. These improvements enable faster operation of thin-wall molds with improved consistency.

All electric injection molding machines offer precise pressure and position control

Thin-walled parts require extremely high precision. During the short, high-speed filling process required for thin-wall injection molding, even slight deviations in screw position, injection speed, or holding pressure can result in visible weld lines, flash, or short shots. All-electric injection molding machines offer more precise position and pressure control because the electric drive provides direct, real-time control of the injection screw and clamping mechanism. In contrast, hydraulic systems rely on pressure-compensated flow and proportional valves, which introduce hysteresis and slow down the feedback loop.

Topstar’s all electric injection molding machines can achieve positioning repeatability of ±0.01 mm and pressure control resolution of less than 0.5 bar on the injection axis. In production, this accuracy reduces variations in shot weight and instantaneous cavity pressure. For example, in injection molding, migrating a 0.6 mm wall-thick PP container from a hydraulic to an all-electric machine reduced the standard deviation of shot weight by approximately 40% and the dimensional variation across 10 cavities by approximately 30%. These values were achieved only when the equipment was paired with a high-performance feed screw and optimized nozzle design.

Faster, Repeatable Injection Profiles and Cycle Optimization

Speed is also crucial for thin-wall injection molding. Thin-walled parts require extremely fast injection speeds to prevent premature solidification at the gate and ensure complete cavity filling before skin formation occurs. Here, all electric injection molding machines again hold the advantage. Electric screw and linear motors deliver high-speed acceleration and deceleration with precise timing, enabling controlled peak injection speeds and near-instantaneous changeovers.

Topstar TEll all electric injection molding machine typically achieve peak injection accelerations two to four times higher than comparable hydraulic presses while maintaining precise position control. This capability enables molders to use very short fill times without sacrificing repeatability. Furthermore, many hydraulic presses exhibit drift during the first few shots after a mold change or temperature fluctuation. All electric platforms recover setpoints within a few cycles, resulting in more predictable ramp-up and shorter run-to-quality times.

All electric injection molding machines offer greater energy efficiency, stability, and consistent melt conditions

Thermal management is critical for thin-walled parts, as melt temperature and viscosity directly impact fillability and skin quality. All-electric presses offer not only improved energy efficiency but, more importantly, improved thermal stability. From an energy perspective, servo-driven motors convert electrical energy into kinetic energy, consuming less energy than hydraulic pumps operating under continuous load. Our research data shows energy savings of 30% to 60%. In addition to lowering electricity costs, lower machine heat generation also reduces the heat load within the production cell.

On the other hand, thermal stability directly improves part consistency. When the injection molding machine‘s barrel, nozzle, and mold are thermally stable, the resin’s shear history and melt temperature remain consistent from shot to shot. Furthermore, without hydraulic oil, melt temperature deviation can be reduced from ±3–5°C with traditional hydraulic systems to ±0.5–1.5°C with fully electric systems. This reduces undershot shots and fluctuations in surface quality.

Cleaner operation, reduced maintenance, and lower contamination risk

Traditional injection molding machines consume large amounts of hydraulic oil, resulting in maintenance downtime and contamination risks associated with components such as pumps and valves. The oil circulating in the hydraulic system can leak, contaminating tools or generating fumes. All electric injection molding machines have fewer fluid interfaces, resulting in fewer leak points and reducing the potential for contaminants to transfer to the mold or molded parts. In the production of high-cavitation, thin-wall parts, such as food packaging or medical components, the reduced risk of oil or particle contamination is a significant quality advantage, simplifying certification and cleaning procedures.

Data from electric injection molding machines in production typically indicate that less preventive maintenance is required for the core motion system. In contrast, hydraulic presses require constant attention to seals, filters, and pumps to ensure optimal performance. As a result, average monthly maintenance hours for all-electric production lines are typically 20% to 40% lower.

Advanced Process Monitoring, Ensure Thin-Wall Quality

Topstar’s all electric injection molding machines, under a unified control system, capture higher-fidelity process data—screw position at millisecond intervals, cavity pressure and temperature synchronized with motion events, and energy consumption per shot.

For thin-wall parts, high-resolution cavity pressure sensors, combined with the injection molding machine’s fast response time, enable closed-loop cavity pressure control, allowing for adjustments to holding pressure and cooling on a shot-by-shot basis. This reduces wall thickness variation and minimizes warpage. At the same time, predictive maintenance and faster mould troubleshooting can be performed directly within the injection moulding machine’s control panel, allowing engineers to correlate environmental conditions, machine drift, and part geometry deviations, and make adjustments on the fly to ensure production quality.

Delivering thinner, higher-quality thin-walled parts

From a practical production perspective, manufacturers who switch to all electric injection molding machines for thin-wall production typically experience increased output, reduced cycle variability, and a lower total cost of ownership, thanks to energy savings and reduced maintenance costs. This allows them to produce thinner, higher-quality parts at competitive cycle times.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/08/15

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/08/15

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/08/15

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/08/15

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar