What kind of clamping system is needed for large injection molding machine with high clamping force?

2025/08/16 By le zhan

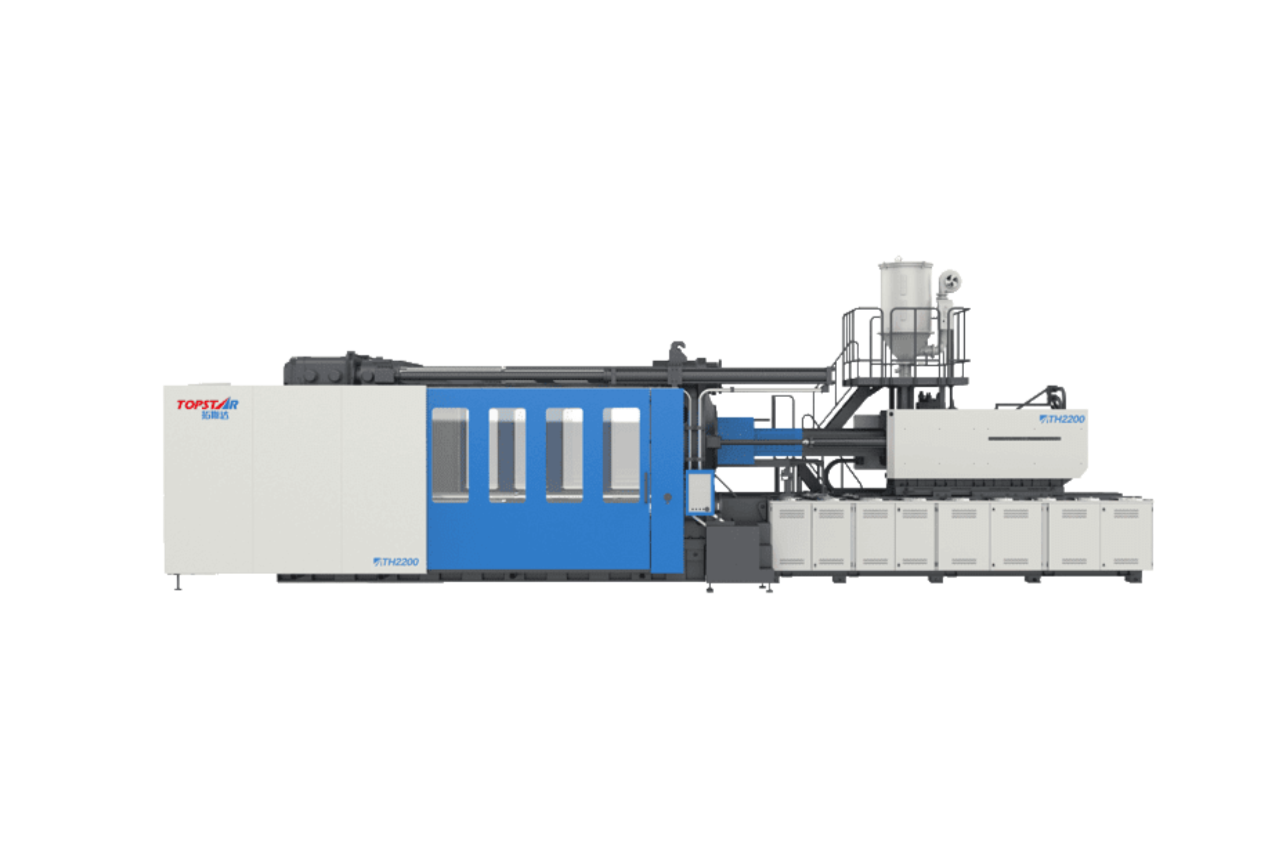

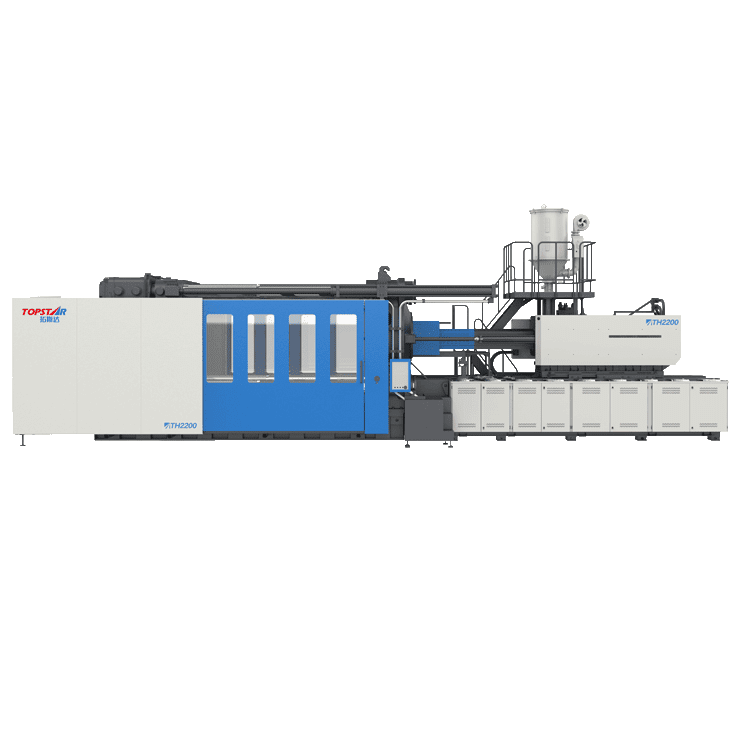

For the large injection molding machine that require high clamping forces, the clamping system has a significant impact on production accuracy, uptime, and safety. In fact, for large-tonnage, high-clamping-force injection molding machines, we utilize a multi-cylinder direct pressure clamping design. This approach expands clamping capacity without concentrating the load on a single actuator. It improves platen parallelism under extreme loads and provides the stability necessary for the injection molding machines to operate reliably with large, complex molds over millions of cycles.

Clamping Requirements for Large Injection Molding Machine

For large injection molding machines, the clamping system must provide consistent and uniform force across a wide platen area while maintaining platen stiffness and parallelism within very tight limits. It must be able to accelerate and stop the platen quickly, achieve repeatable positioning, and protect the mold by sensing and responding to anomalies within milliseconds. These technical requirements are crucial in large-scale production. They involve the interplay between platen design, guide rail selection, and other factors to control deflection under load. The control system must operate with high bandwidth and synchronized cycles to maintain repeatability. Integrated sensing technology is crucial for preserving process stability during the injection molding process and for promptly detecting and preventing jams or misalignments. In production, this combination reduces scrap, prevents mold damage, and maintains cycle-to-cycle consistency.

Why is multi-cylinder direct pressure clamping the preferred configuration for large injection molding machine?

Large injection molding machine place unique mechanical demands on themselves, including heavy mold weights, large projected areas that generate high separation forces, complex multi-cavity molds that require uniform clamping across a wide span, and frequent heavy-load cycles. In these environments, single-ram or single-toggle designs often concentrate loads and amplify platen deflection, resulting in uneven contact. Therefore, Topstar utilizes a multi-cylinder direct pressure clamping system, which applies clamping force more evenly. This makes it easier to maintain platen parallelism, avoiding minor misalignments that can lead to localized high stresses. In practical production, this can reduce scrap and unplanned downtime on large injection molding machines.

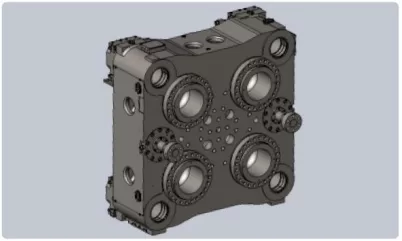

Furthermore, multi-cylinder systems offer greater scalability. Instead of designing a single, massive cylinder block and the associated structural reinforcement, engineers can choose multiple, medium-sized cylinder blocks, each with a combined capacity that achieves the required clamping force. This modular design reduces manufacturing and maintenance complexity, and also simplifies installation and transportation.

Structural Layout and Platen Design

The way the machine structure receives and transmits clamping force determines mold alignment and life. For multi-cylinder systems on large injection molding machines, Topstar designers optimized platen rigidity and support geometry so that each cylinder’s load path contacts the platen in a manner that minimizes bending and shear. Platen thickness was increased, ribs were added, and local reinforcement was implemented under each actuator to prevent stress concentrations.

Additionally, regarding tie-bar versus tie-barless configurations, both are compatible with multi-cylinder clamping; however, each has its advantages and disadvantages. Traditional tie-bar machines use cylinders to move the platen and transmit lateral loads via guide rods. Tie-barless frames provide complete contact with the platen, making mold loading easier, a significant advantage for large molds. Multi-cylinder clamping naturally integrates with tie-barless designs, as actuators can be positioned around the platen without interfering with each other. Regardless of the configuration chosen, the structural connection between the cylinders and platen must maintain precision.

Drive Technology—Hydraulic, Electric, and Hybrid

Hydraulic systems remain the primary drive method for the large injection molding machine due to their high power density and ruggedness; however, more modern designs are increasingly incorporating electric or hybrid systems where appropriate. Hydraulic cylinders offer compact energy storage and can deliver extremely high thrust at a relatively low cost per ton. Typical design port operating pressures range from tens to hundreds of bars, enabling multiple hydraulic cylinders to achieve thousands of tons of thrust on a single frame. Hydraulic systems also deliver smooth thrust and fast response when used in conjunction with proportional valves.

Electric drive mechanisms offer advantages in precision, energy efficiency, and cleanliness. For large-frame injection molding machines, fully electric clamping requires robust electric drives and large servo motors. Currently, cost and size limit this approach to the highest tonnages, but hybrid systems employ electric clamping assistance for fine positioning and utilize hydraulics to provide overall force.

Control, Safety, and Maintenance for Reliable Production

Rugged and durable multi-cylinder clamping systems also require modern control and safety measures. Closed-loop control utilizes feedback from pressure sensors and linear position sensors to synchronize cylinder pressure and displacement. In terms of safety, overpressure relief valves, mechanical locks for mold maintenance, and interlocks that prevent access to the mold under pressure protect personnel and equipment. Furthermore, real-time monitoring enables the analysis of clamping force trends, leak detection, and vibration/temperature monitoring—providing early warnings of issues before they cause production losses.

Maintenance in the hydraulic system requires timely filter and oil changes, seal inspections, and preventive inspections of the manifold and proportional valve cores. For electric/hybrid equipment, commissioning requires force mapping across the entire platen, checking platen parallelism under load, and running endurance cycles to verify thermal and mechanical stability. These measures ensure that multi-cylinder clamping systems provide consistent clamping force and part quality over years of high-load production.

What can the right clamping system offer?

Large injection molding machines that require high clamping forces necessitate a clamping system that provides a uniform, repeatable, and sustainable preload on wide platens and heavy molds. Multi-cylinder direct pressure clamping can distribute force, minimize platen deflection, provide redundancy, and integrate with modern closed-loop control to provide reliable, high-precision clamping for complex multi-cavity molds. These elements work together to maintain platen parallelism and achieve precise repeatability.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/08/16

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/08/16

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/08/16

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/08/16

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar